-

DEYING Rubber Compression Molding FAQ

1-How to get a quotation for a compression rubber molding? Please provide a drawing or a sample of your part for us check first. Alsto we need to know your estimated annual usage requirements and material of rubber part, if the material is unspecified or unknown, please ...Read more -

The benefit with DEYING Rubber Compression Molding

– Trusted experience to solve your problems from design to price to delivery – try us! – Fast delivery time(10-15 days) – Competitive pricing on a variety of rubber parts – We aggressively monitor raw material costs to maintain the lowest possible pricing – Green initiat...Read more -

DEYING Compression Moulding introduce

DEYING Compression Moulding introduce DEYING MOLD supplying Rubber Molding is a full-service rubber products manufacturer with more than 20 years of experience. Depend on our rubber product manufacturing capabilities to meet the needs of the transportation, medical, elec...Read more -

What are the advantages and disadvantages of rubber compression mould?

Advantages of Rubber Compression Molding Rubber Compression Molding offers advantages over other methods by providing: Tooling savings Short setup time (saves on short production runs) The capacity to process stiff, high durometer materials Ideal for large parts that re...Read more -

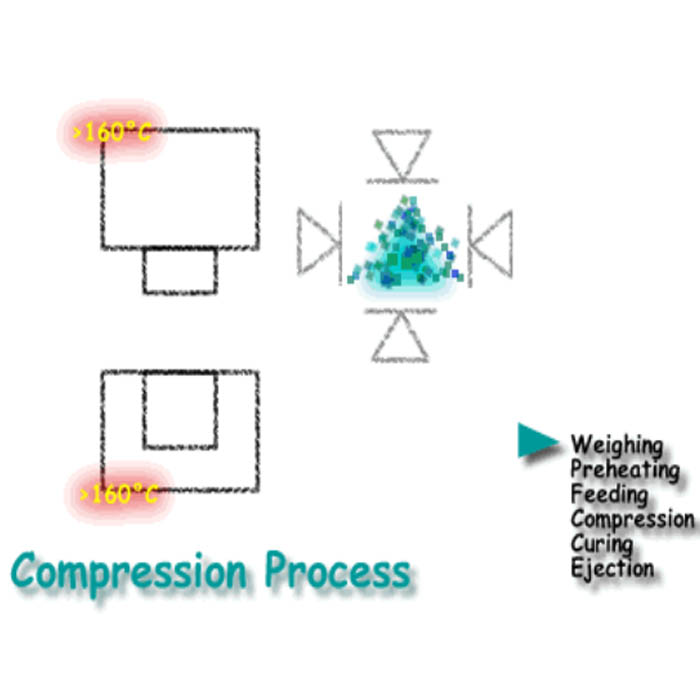

What is Process of Rubber Compression Molding ?

The rubber compression molding process uses a preformed piece of uncured rubber that is placed in an open mold cavity. The mold is preheated to an elevated temperature. As the mold closes in the press, the material is compressed and flows to fill the rubber mold cavity. ...Read more -

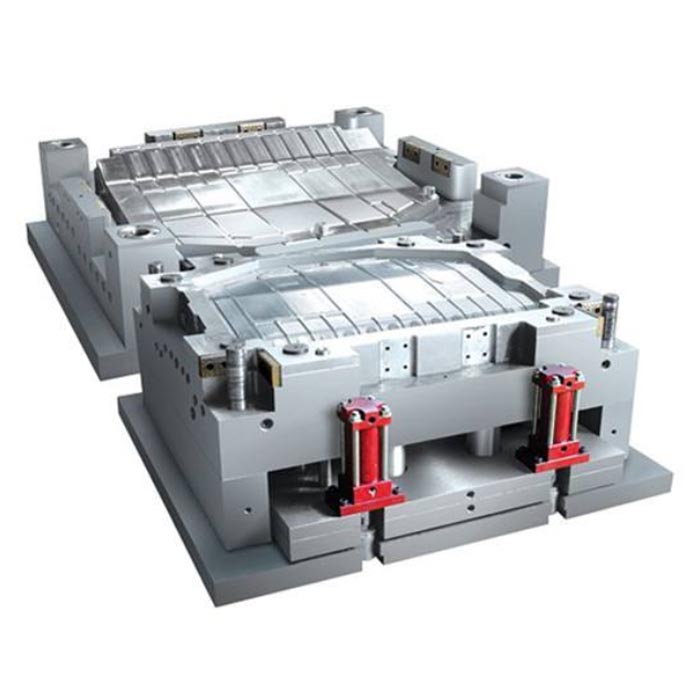

Rubber Compression Molding introduction

The first rubber molding process, rubber compression molding, is ideal for low to medium volume production of rubber products. Compression molding is a widely used economical production method for low volume production of medium to large parts. It is the best rubber mol...Read more -

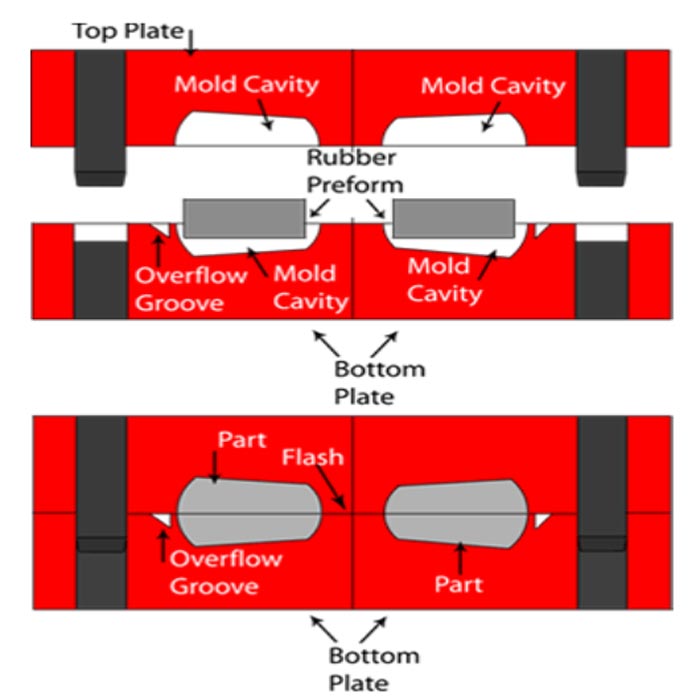

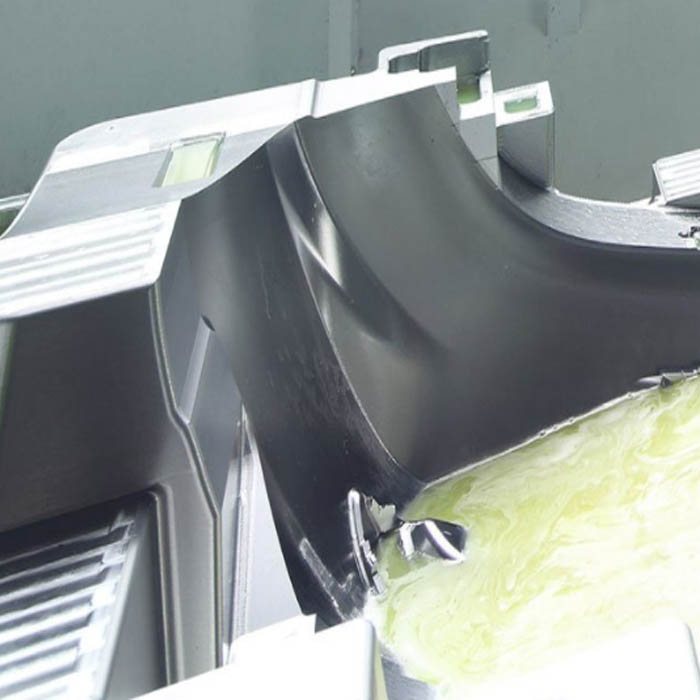

Rubber Compression Molding Process Description

The rubber compression molding process begins with a piece of uncured rubber which has been performed to a controlled weight and shape. This preform is placed directly into the rubber mold cavity prior to mold closure. As the mold is closed, the material is compressed be...Read more -

Advantages and Disadvantages of Rubber Compression Molding

Advantages of Rubber Compression Molding: Tooling can be less complex and lower cost to construct Lower percentage material runner scrape vs. traditional injection or transfer molding Process is suitable from most elastomers and cure systems Disadvantages of Com...Read more -

Rubber Compression Molding Steps

Want to know the production steps of rubber compression molds? Let DEYING MOLD come and chat with you today 1.) Uncured rubber is preformed to control weight, shape and specification 2.) Rubber preform is placed into the mold cavity 3.) Rubber molded is closed compressin...Read more -

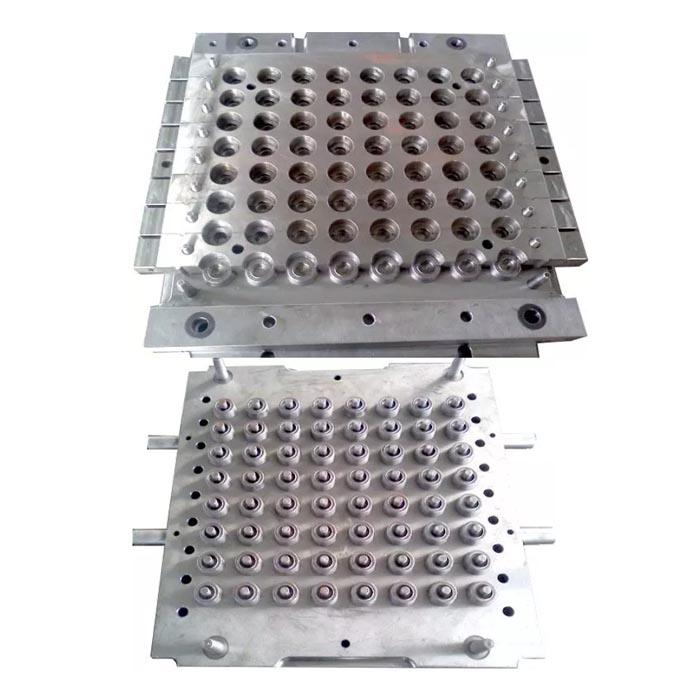

Is compression molding cheap?

Compression rubber molding is often the most cost-effective manufacturing method if you need to produce simple, mostly flat, large parts. ... To offset the cost associated with compression molding's long cycle times, manufacturers can use a mold with multiple cavities to...Read more -

What is rubber compression molding?

Compression rubber molding involves taking rubber compound or mixed raw material and making "pre-forms" that are close to the shape of the end product. These shapes are then loaded, typically by hand, into an open mold. The mold is closed, the rubber cured, and then de-m...Read more -

What are the commonly used rubber product molds?

At present, my country's rubber products industry is developing rapidly, the types of rubber products are increasing day by day, and the output is also increasing day by day. With the continuous improvement of rubber production equipment and production technology, the de...Read more -

Rubber product mold design and demoulding method?

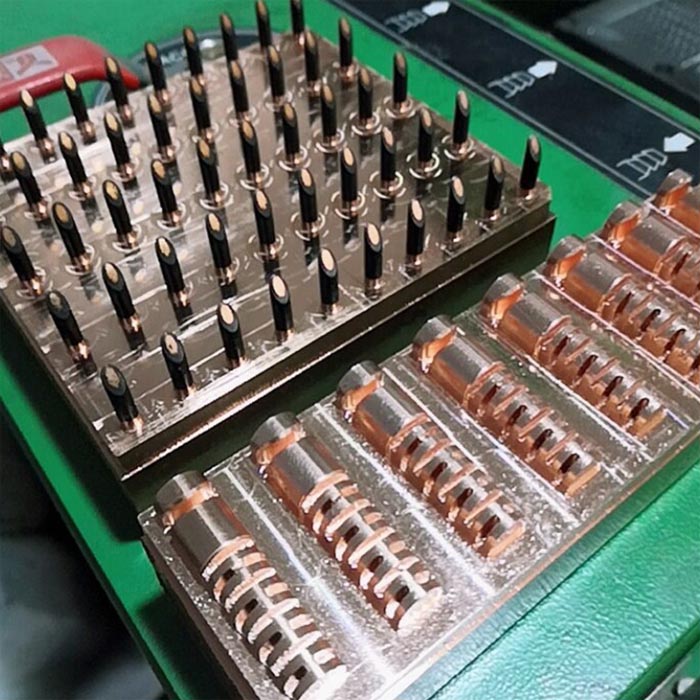

Rubber product mold design and demoulding method? 1. Rubber product mould (1) The rubber product mold must be easy to demold when designing, accurately conform to the contour and shape of the rubber product, and the structure must be simple, reasonable, easy to operate, ...Read more -

The difference between rubber product mold structure and plastic mold structure

Mass production of rubber products and plastic products requires molds to be produced. This is the principle of mass production. Rubber molds are mainly based on molded products, so what I will introduce next is molded rubber molds. Rubber molded products are widely used...Read more -

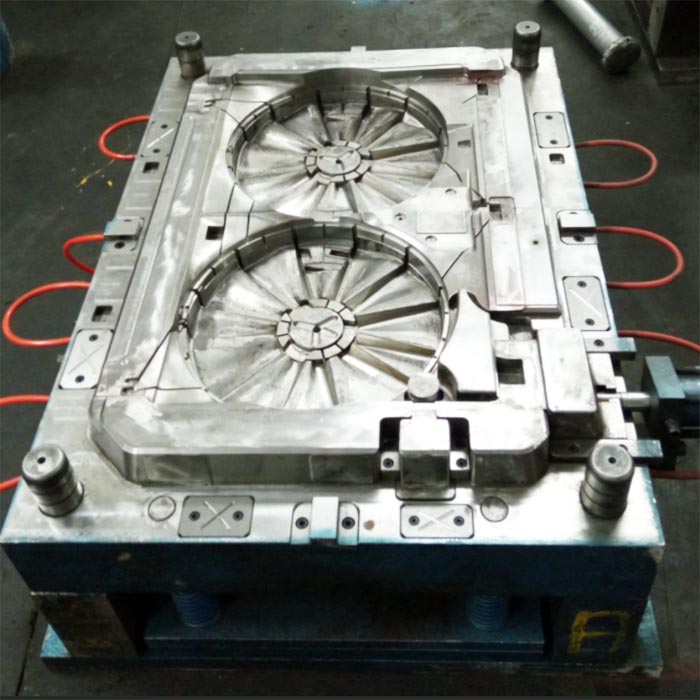

Rubber product mold classification

In order to vulcanize rubber products with accurate dimensions, mold designers must be familiar with the shrinkage of various rubbers with different hardness and rubber content. The different pressing principles of rubber products moulds can be divided into three main ca...Read more -

What is the difference between LFT mold and SMC mold?

1. LFT introduction: LFT, long fiber reinforced thermoplastic material, English is Long Fiber reinforced Thermoplastics, which is compared with ordinary fiber reinforced thermoplastic materials. Normally, the fiber length in fiber reinforced thermoplastic materials is le...Read more -

Why is the fiberglass mold deformed?

1. Fiberglass products have a certain shrinkage rate of about 3% when they are cured. If the strength of the FRP mold is not enough, the product may have a certain extrusion effect on it during the curing process and cause the mold to deform; 2. The glass fiber reinforce...Read more -

Thermoset plastic mould manufacturer

Place the molded plastic in the cavity of the metal mold, then close the mold under heating and pressurization to make the plastic melt, flow, and fill the cavity. After proper venting, the plastic will be fully cross-linked after the pressure is maintained. Cured into p...Read more -

Thermosetting plastic mold manufacturing features

(1) the cavity and core size of the compression mold is determined by the shape and dimensional accuracy required by the plastic parts. Because the mould is in heating (60 ℃ -- 150 ℃) conditions of the job, so when heated size will swell, and cavity after cooling, the si...Read more -

What is a hot press mold?

The hot pressing mold usually uses a hydraulic press, and the cavity and core are fixed on the upper and lower pressing plates of the machine. Once the material is placed in the open mold, the machine is turned off, the mold is heated, and then the pressure forces the ma...Read more -

How to choose thin wall lunch box mold steel material?

The thin-walled meal boxes for take-out packaging are very popular, and they are also indispensable products in life. The demand for one-time packaging meal boxes is very large, and the packaging box mold market has also caught up with the development trend. Disposable l...Read more -

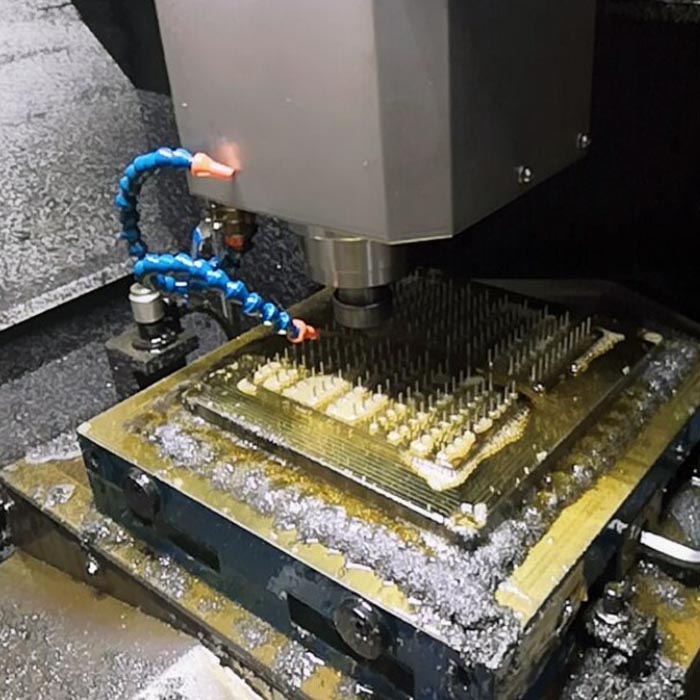

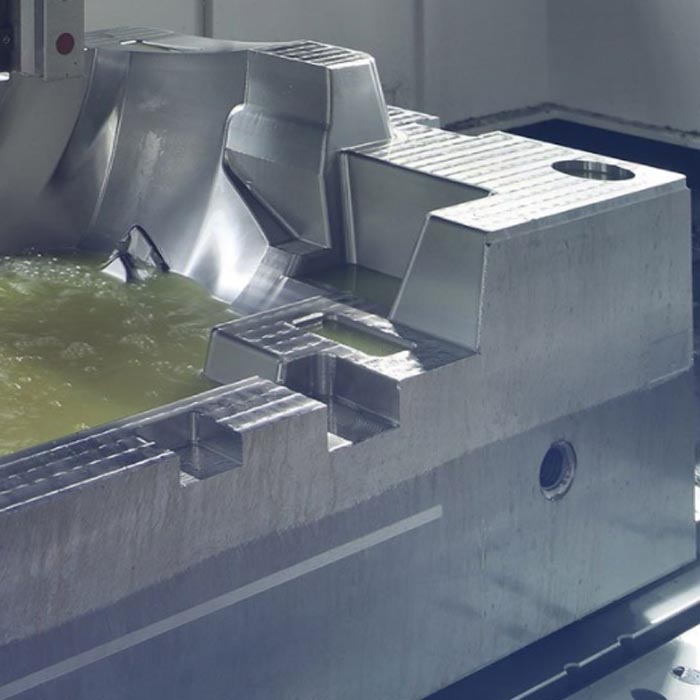

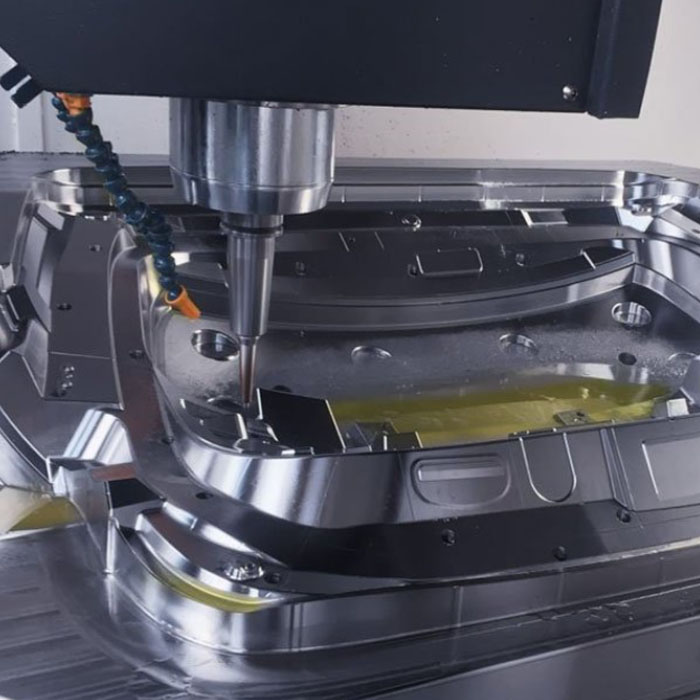

How to make a good mold?

DEYING is a manufacturer of plastic injection molds and compression molds, with unique management concepts and development directions, and is committed to becoming an innovative enterprise for injection molds and compression molding technology. How to make a good quality...Read more -

DEYING Plastic Battery Box Mould

Battery shells are widely used in electric cars, battery cars, electric motorcycles, electric logistics tricycles, etc. Different vehicle models use different models, such as L1, L2, L3, L4,... N70, N100, N150, N200 Wait. DEYING mold has rich experience in manufacturing ...Read more -

chinese national holiday 2021 Golden Week Holiday plan DEYING MOLD

Chinese National Day is celebrated on October 1st every year to commemorate the founding of People’s Republic of China. On that day, lots of large-scaled activities are held nationwide. The 7-day holiday from Oct. 1st to 7th is called 'Golden Week', during which a large ...Read more