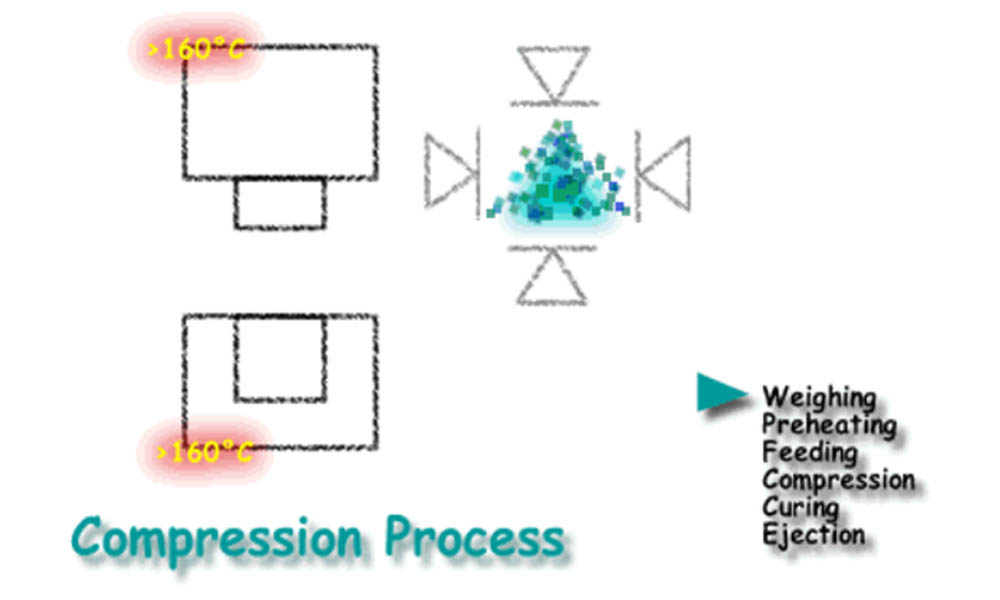

1. Fiberglass products have a certain shrinkage rate of about 3% when they are cured. If the strength of the FRP mold is not enough, the product may have a certain extrusion effect on it during the curing process and cause the mold to deform;

2. The glass fiber reinforced plastic mold itself also has a shrinkage rate of about 3% when it is made. It is a common phenomenon that the size after curing is deformed compared with the design. It is a very common phenomenon to add a low shrinkage agent or simply add a filler to reduce the shrinkage.

Fiberglass molds include female molds, male molds, paired molds, etc. The specific internal type to be selected depends on the structure, process, and quality requirements of the product. No matter which type of internal type is used, analyze the product structure before doing it, and consider how to divide it to facilitate demoulding.

After the mold is finished, some need to make stiffeners. If possible, the mold can be placed in the drying room (temperature around 40) for 24 hours. Demoulding, cutting off burrs, sanding, (Eagle brand water sandpaper), generally start from 600 to 2000 according to the surface of the mold, (pay attention to the directionality when water sanding) check the interval. For polishing, use No. 1 polishing agent first, and then use No. 3. Waxing or release agent after treatment.

MB/Wechat/Whatsapp:+0086-13456489912

sophiemould@foxmail.com

Post time: Dec-01-2021