The rubber compression molding process uses a preformed piece of uncured rubber that is placed in an open mold cavity. The mold is preheated to an elevated temperature. As the mold closes in the press, the material is compressed and flows to fill the rubber mold cavity.

The combination of elevated temperatures and high pressures activates the vulcanization process and curing of the rubber compound. Once an optimal cure is reached, the part hardens and cools then the mold is opened and the final part removed. The next rubber preform is inserted into the mold and the cycle repeats.

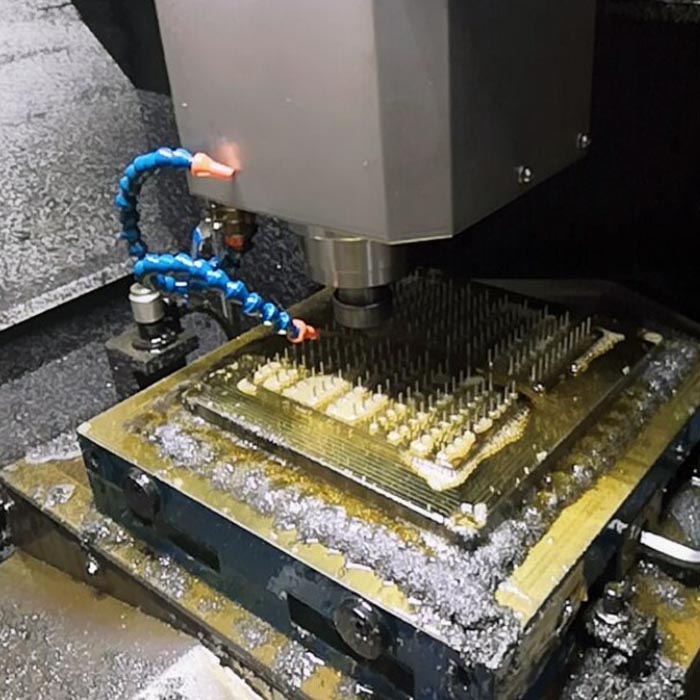

The basic compression mold is usually a two-piece construction consisting of a top and bottom plate. Half of the part cavity is usually cut into each plate of the mold. A trim area is created by grooves cut around each cavity which allows the excess rubber to flow out of the cavity. Compression molds are typically secured between heated press platens. The molded parts require trimming to remove the groove overflow. An additional bake cycle may be required for partially cured parts.

For more information on the rubber and plastic design processes please visit and contact us.

MB/Wechat/Whatsapp:+0086-13456489912

sophiemould@foxmail.com

Post time: Dec-19-2021