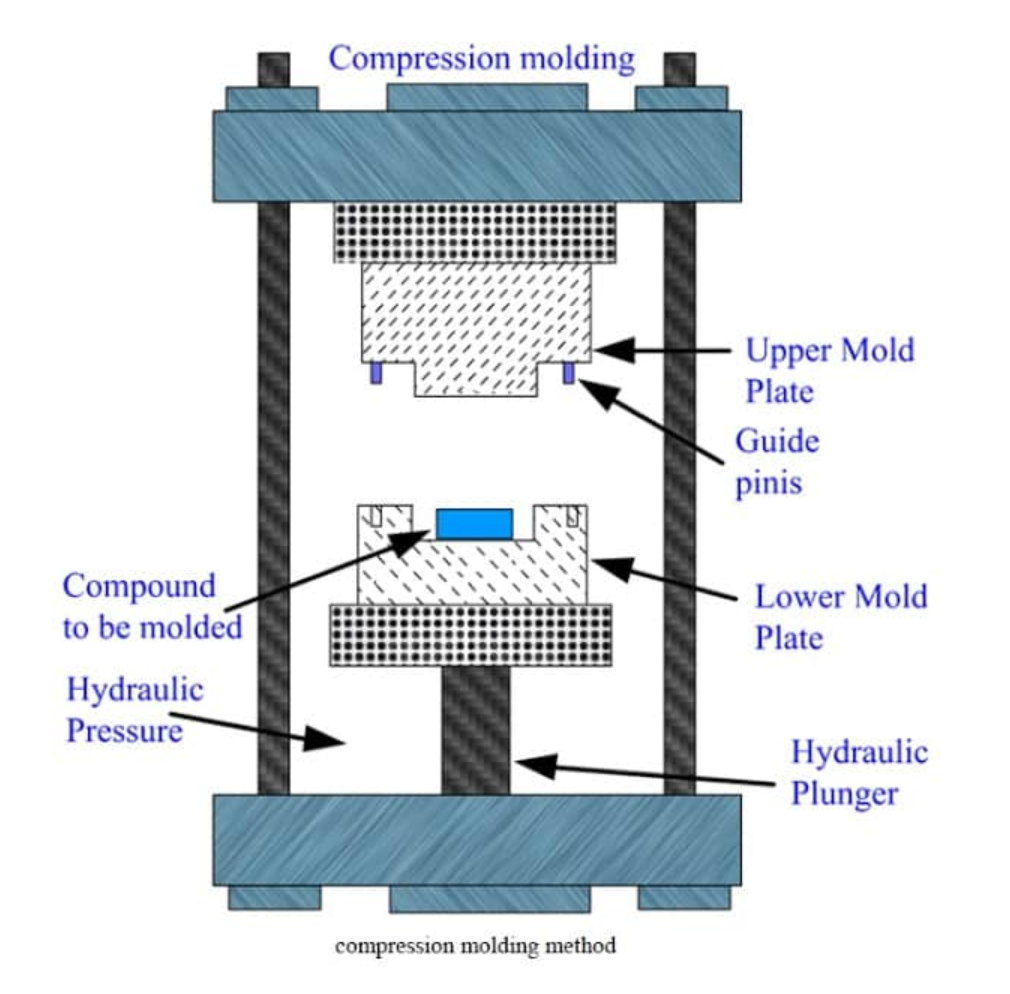

The bulletproof shield is produced by heat compression produced by bulletproof shield mold, which is a compression molding process.

tactical shield is a highly maneuverable micra shield, which is lightweight, weighing just 3.7lbs, and ergonomically designed to ensure maximum protection in all tactical situations. The shield has an integrated weapon mount, allowing one handed operation of rifles and hand guns.

COMPRESSION MOLDING

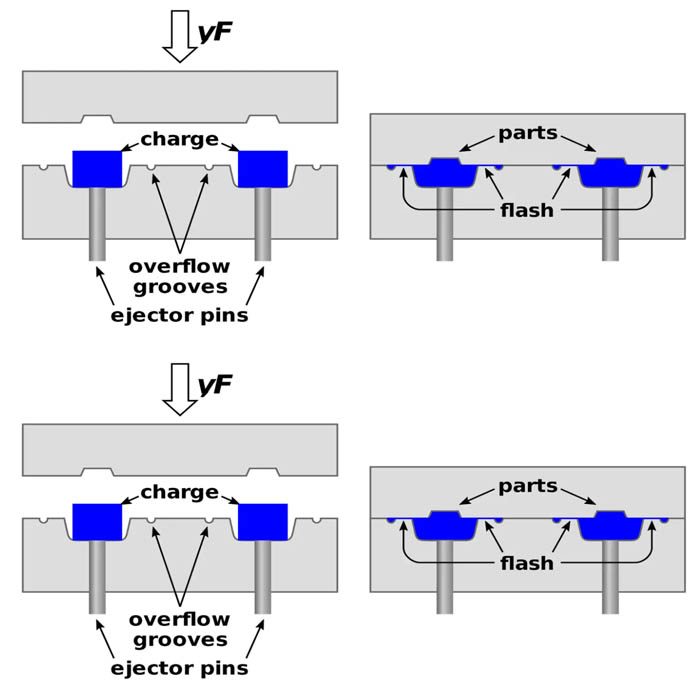

Compression is a molding process in which the required material is placed in an open, heated mold cavity. The mold is then closed and pressure is applied to the mold with a large hydraulic press to make the material contact all areas of the mold. Presses are divided into mechanical and hydraulic types, currently hydraulic type is the main type.

Compression molding is the most common manufacturing process for thermoset and thermoplastic polymer composites. Usually used to produce high-volume composite parts, such as automotive parts. There are two types of compression molding process, namely cold pressing and hot pressing.

The advantage of compression molding is that it is widely applicable to various compounds. Since devices can be made for certain polymers at room temperature, the problem of mutual reactions between polymers can be alleviated. The compression molding process can help keep the overall project cost to a minimum. Although compared with other technologies, the cost of a single part may be higher. When choosing the most suitable production solution, all aspects of the product, performance and life cycle must be considered. The right solution may not require expensive injection molds, so even if the cost of the parts is higher, overall, the compression molding solution is still as important as ever.

MB/Wechat/Whatsapp:+0086-13456489912

sophiemould@foxmail.com