China Uhmwpe Ballistic Shield moulding manufacturers from taizhou DEYING mold,Spectra Shield is a composite material (specifically, an ultra-high-molecular-weight polyethylene (UHMWPE) fiber) used in bulletproof vests and vehicle armour

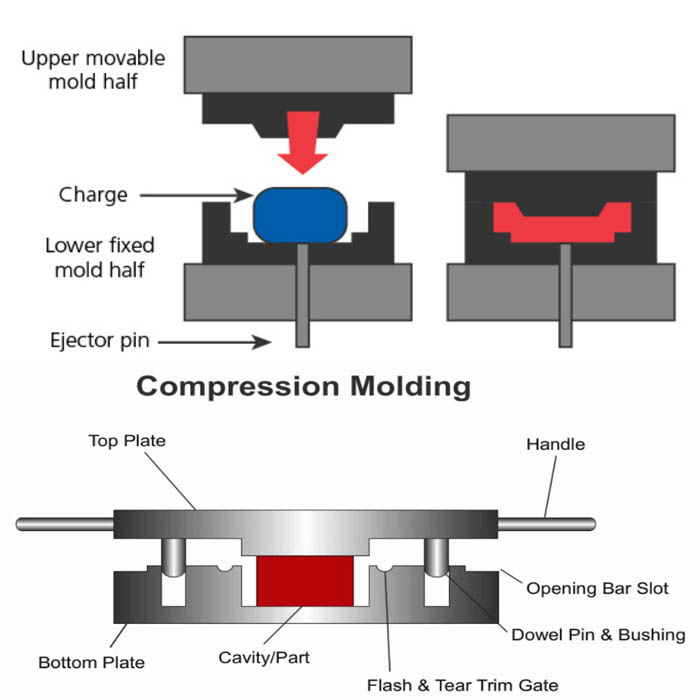

COMPRESSION MOLDING

Compression molding is the process of molding in which a preheated polymer is placed into an open, heated mold cavity. The mold is then closed with a top plug and compressed in order to have the material contact all areas of the mold. This process is able to produce parts with a wide array of lengths, thicknesses, and complexities. The objects it produces are also high in strength, making it an attractive process for a number of different industries.

Thermoset composites are the most common type of material used in compression molding.

Compression molding is a versatile manufacturing process used by small and large production companies alike for creating a wide variety of parts.

What Is Compression Molding?

Compression molding is a manufacturing process where a measured amount of molding material that’s generally preheated (typically referred to as a charge) is compressed into the desired form using two heated molds.

MB/Wechat/Whatsapp:+0086-13456489912

sophiemould@foxmail.com