In the production process of SMC and BMC products, the way the raw materials are laid is also very important. The paving material needs to adjust the cutting method, size, weight, etc. of the raw material according to the structure of the product, considering the fluidity of the raw material, and the welding position. Improper spreading of materials can cause nicks, cracks and other problems in the product.

All SMC or BMC products have a process of cleaning flash. If it is a high-quality mold, the flash will be very thin, and the cleaning process is very simple. The flash cleaning process can be automated or manually operated by machines.

Summary: Regardless of any mold production process, there will be some problems more or less, the problem is not terrible, just solve it. That's it for the flash treatment of SMC molds. DEYING MOULD strictly controls the production process of products, and each link is followed by professionals to ensure that problems are found and resolved early. Safe production, efficient production, mutual benefit and win-win! If you want to know more about mold manufacturing, please bookmark this site and pay attention to the update of this site in time.

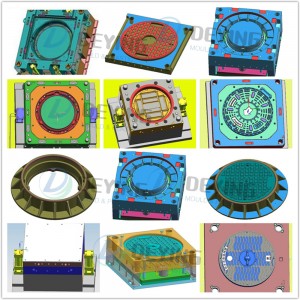

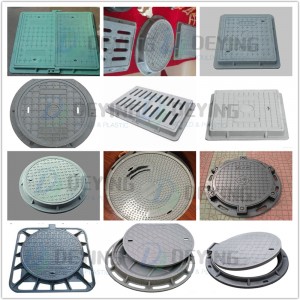

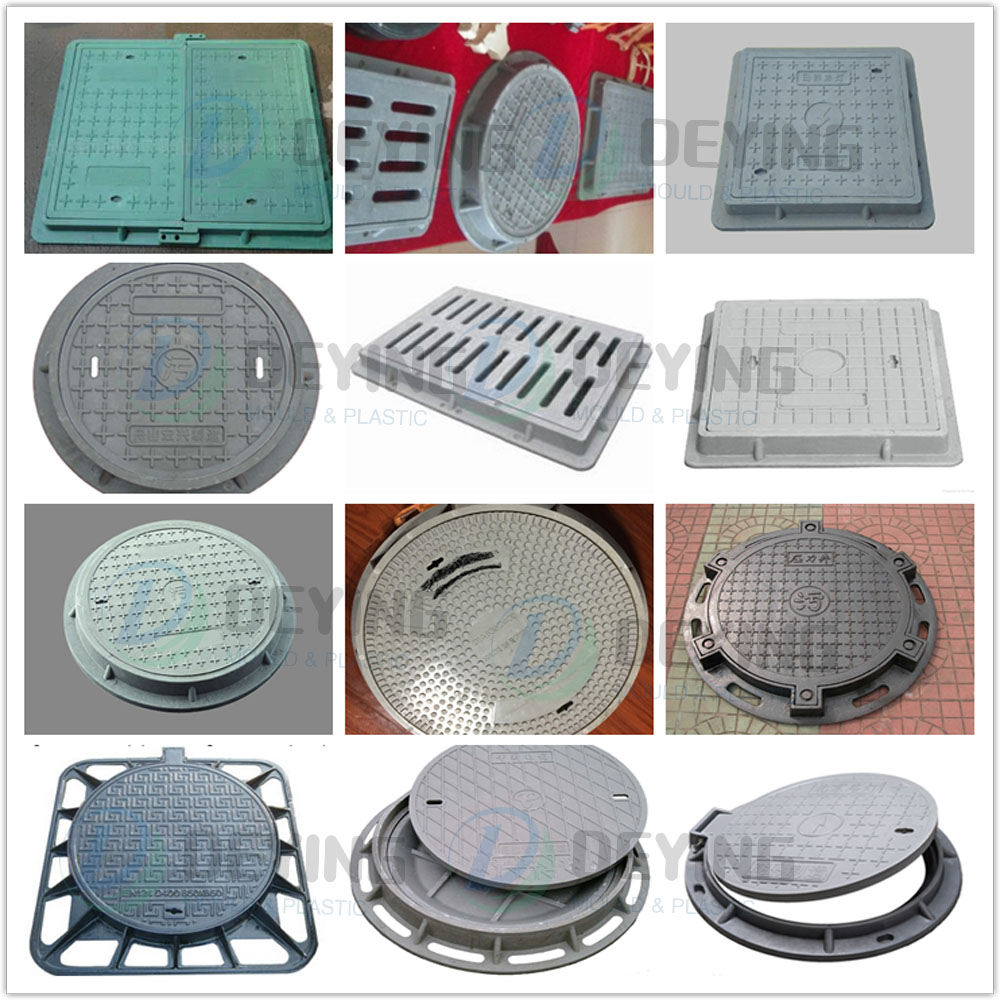

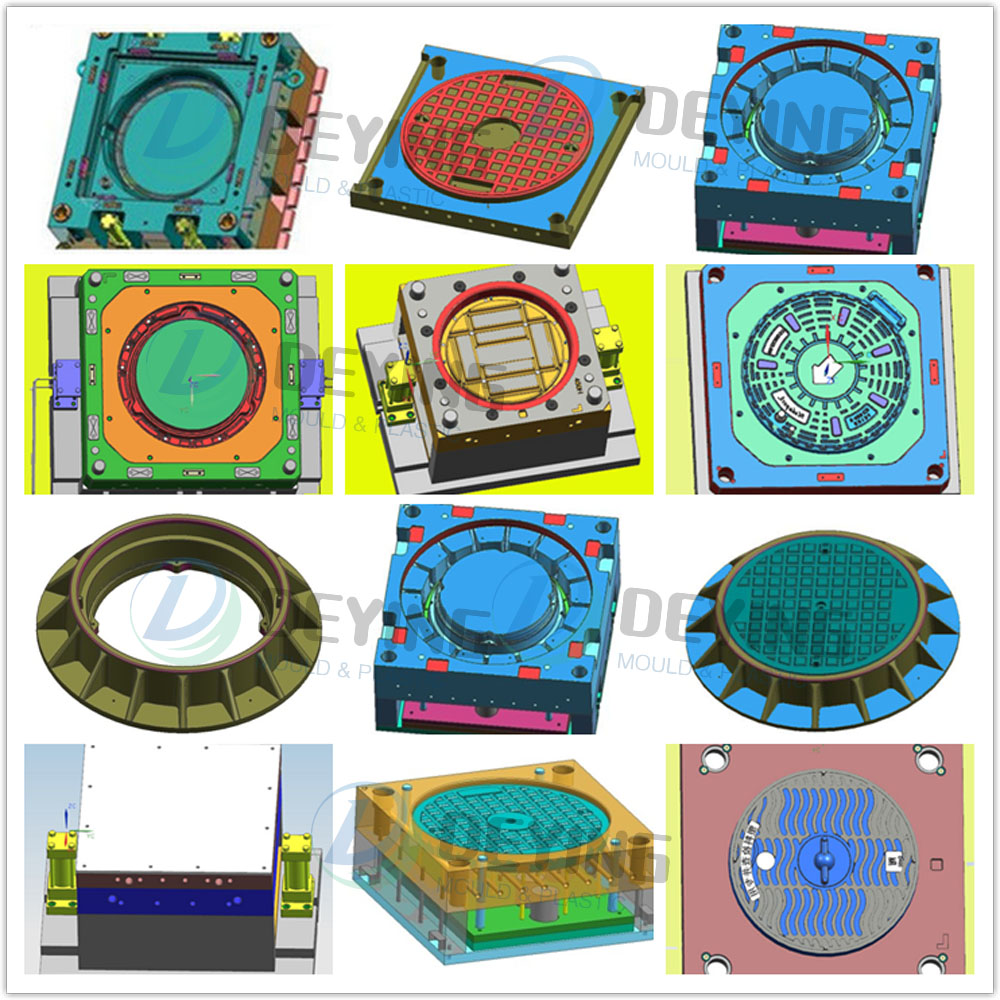

The manhole cover mold of the new composite material is different from the old manhole cover mold. The new product adopts polymer composite material, which is more robust and durable, and has an exquisite appearance, which is conducive to the decoration of the manhole cover and has a great advantage in weight.

The types of manhole cover molds are: cement round manhole cover mold, county municipal manhole cover mold, inspection manhole cover mold, cement water manhole cover mold

Manhole cover molds have also made a good development, and the mold industry has made considerable progress. Plastic molds are mainly divided into compression molding, extrusion molding, blow molding and other processes, which can be processed into molds of different shapes and sizes. At the same time, with the advancement of science and technology, the mold industry is now developing by leaps and bounds, precision and strength have also been developed, and the quality of molds is also improving from time to time.

The quality of the manhole cover mold determines the service life of the manhole cover mold. Major consumer manhole cover manufacturers choose one of the most important elements of the mold. However, when using the manhole cover mold, you should pay attention to the method and method of use, which is also one of the ways to extend the life of the part 1. Pay attention to the following points when using plastic molds. First, before using plastic molds, check whether the appearance of the mold is smooth and whether the plastic mold can be smooth. Then, place the mold in the flat center before filling the cement. It can not only produce high-quality blocks, but also maintain the appearance and shape of plastic molds, and extend the service life of plastic molds.

MB/Wechat/Whatsapp:+0086-13456489912

sophiemould@foxmail.com