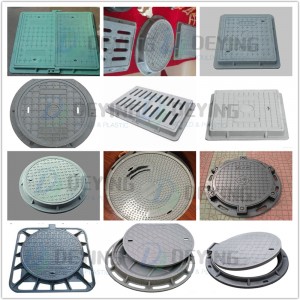

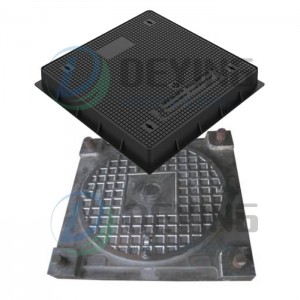

DEYING has always been committed to the development and application of composite materials. Its main product "new open-air fiber glass manhole cover molds" has been widely promoted, applied and recognized at home and abroad.

The company always adheres to the tenet of "science and technology, quality, and integrity", takes "focus on science and technology, and benefits the human society" as its mission, constantly develops and creates advanced equipment that meets the national conditions, and makes unremitting efforts to promote development,SMC Composite Manhole Cover Mouldings maker in taizhou.

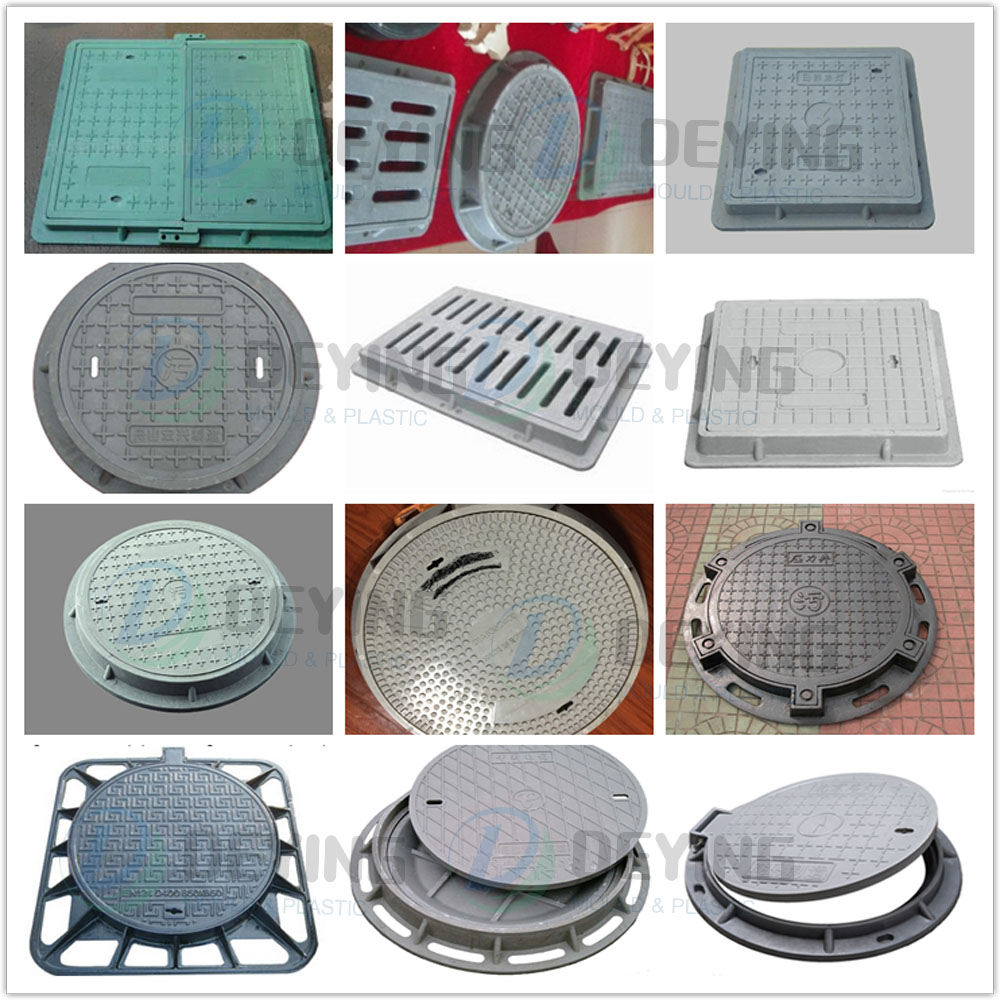

The fiber-reinforced plastic manhole cover uses resin and fiber as the main raw materials, and the product is easy to transport. This product is within the range of -50 degrees -160 degrees, and is resistant to corrosion by various chemical media such as acid, alkali and salt. Aprons and heat are used between the drainage pipes Linking methods such as shrinkage have good adaptability to uneven settlement of the pipe base and resistance to thermal expansion and contraction of materials.

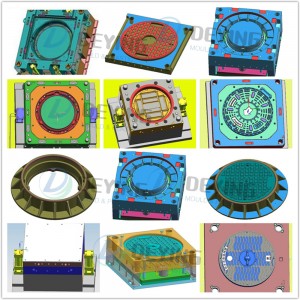

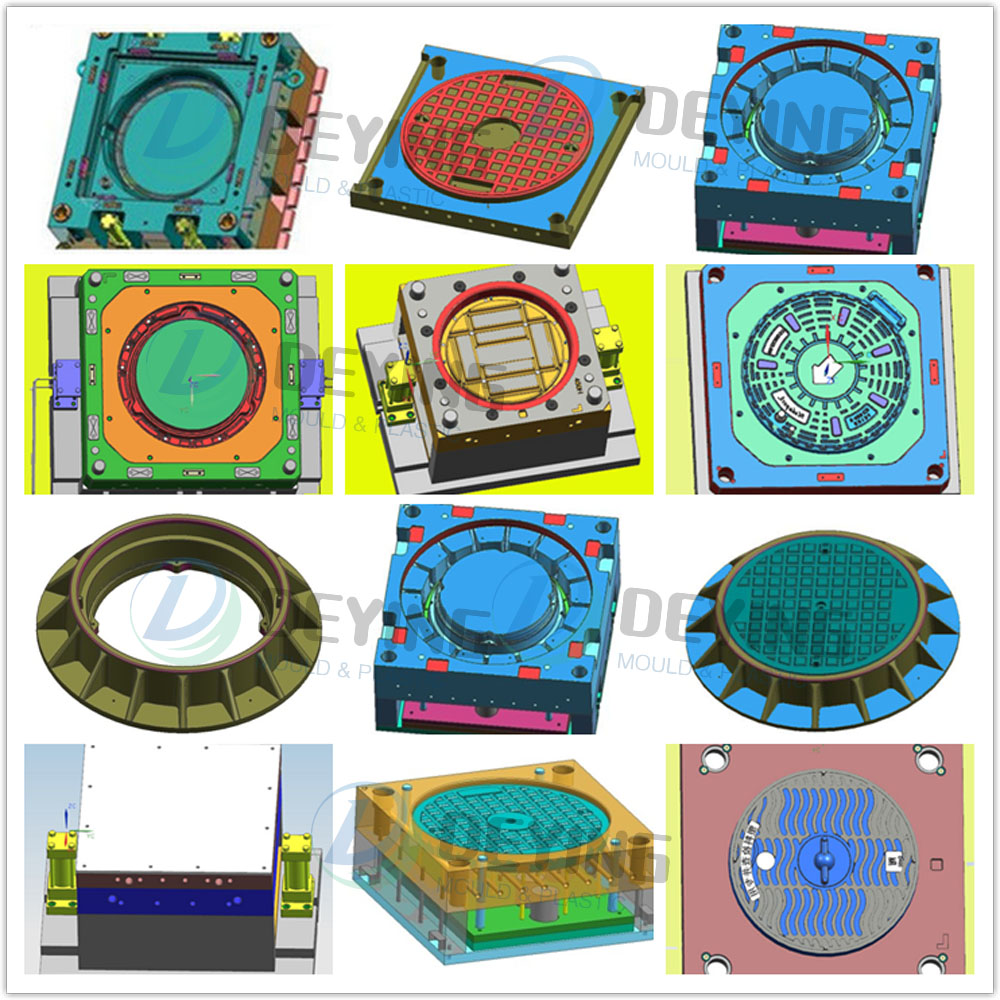

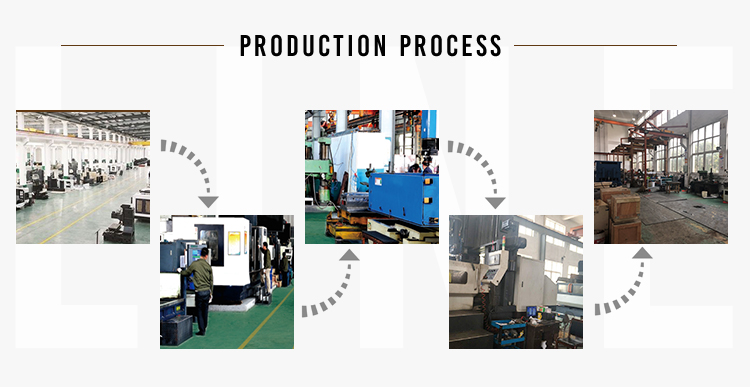

The composite molds we produce have been effectively optimized, have a longer service life, lower manufacturing costs, and their products can achieve higher precision.

Although China is a big country in mold making, it is not a powerful country. To seize the opportunity in the face of the new challenge and achieve sustainable development in the more fierce market competition, we must attach great importance to energy-saving and consumption-reducing operations.

Chinese mold companies will also actively respond in the rapidly developing mold market, expand China's mold market, and become a world mold power. Harmony with service, manhole cover molds should survive on quality. Create brand with after-sales service, and forge ahead from innovative research and development from time to time, so as to build the first brand of molds.

MB/Wechat/Whatsapp:+0086-13456489912

sophiemould@foxmail.com

-

En124 Standard D400 Square and Round Sewer Manh...

-

Hot sales Composite Round Resin FRP Manhole Cov...

-

High Quality and Low Price Fiberglass Plastic S...

-

Composite Round and Square FRP Manhole Cover mold

-

SMC BMC manhole cover mould FRP compression com...

-

New Design Manhole Cover Moulds Plastic with Hi...