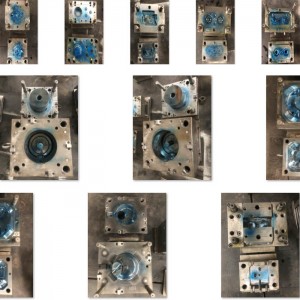

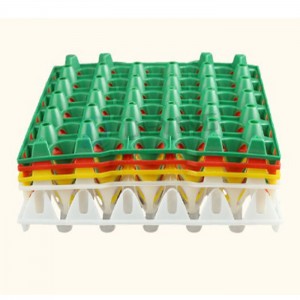

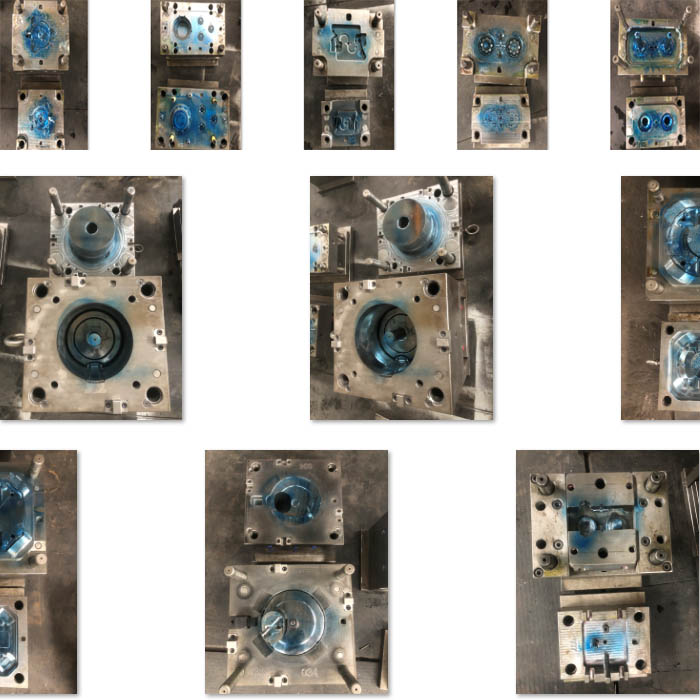

Make juicer molds to DEYING MOULD, with superb craftsmanship and rich experience. One-stop mold service, high precision, parts mold, lower price, higher precision, the choice of 6000+ customers.

There are two main consumer groups for juicers: one is for families with children or the elderly, children are prone to picky eaters but the elderly have bad teeth, and their own juice can satisfy them to get enough nutrition; the other is for the pursuit of fashion and life Tasteful young people, the juicer meets their needs for advocating individual taste.

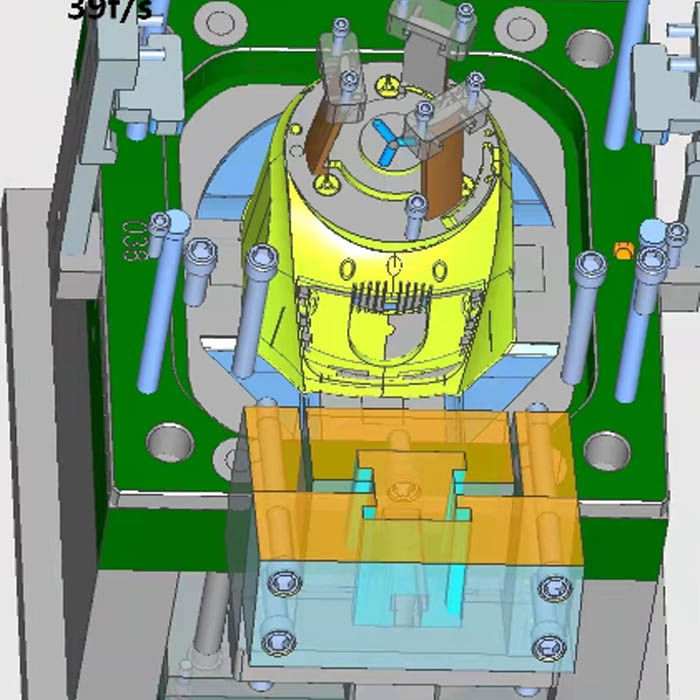

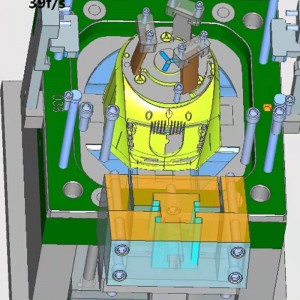

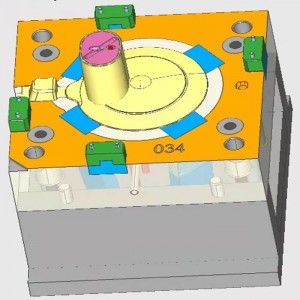

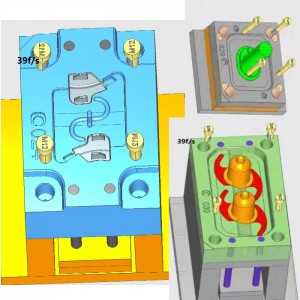

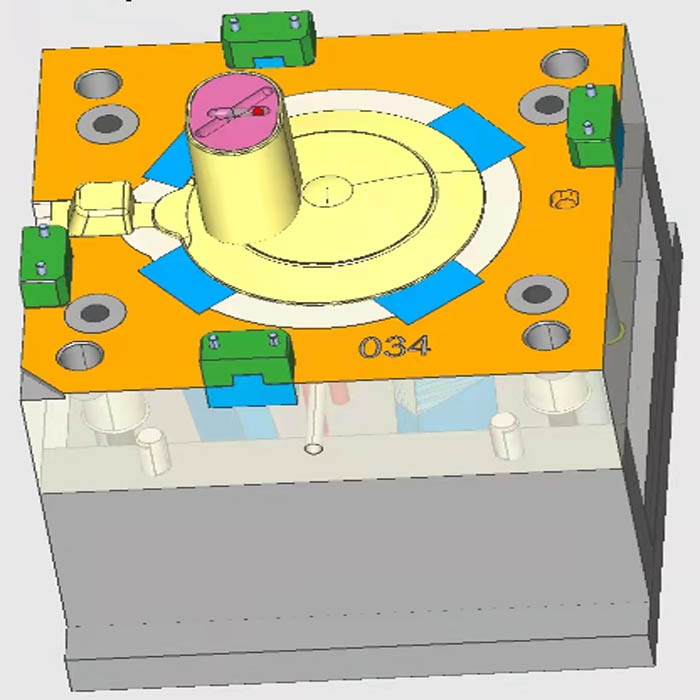

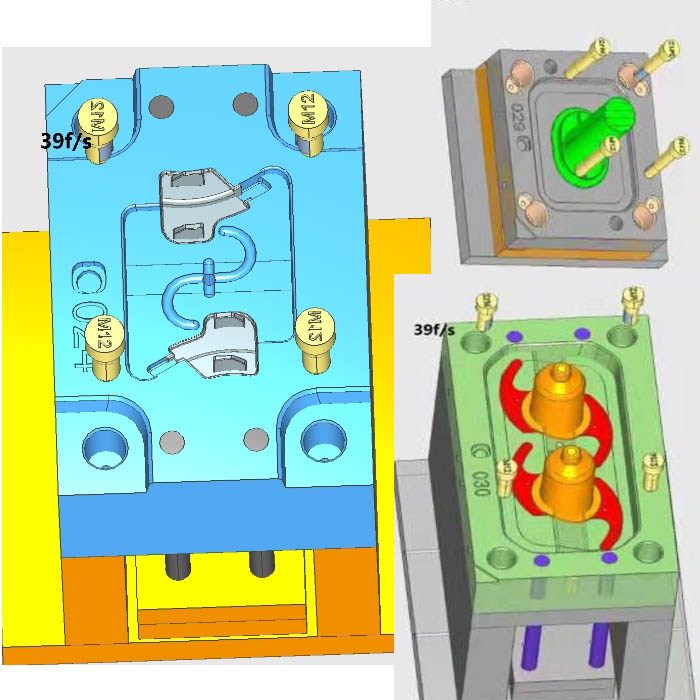

How can I make a mold for an injection molding juicer? First, select the right steel material for the mold base and the mold core cavity. In addition, you must use high-hardness steel as the mold base, and then select the appropriate mold standard parts. A good plastic material filling system requires special hot runner system assistance. Forming, and to ensure that the cooling system achieves the best results. For injection molds, Taizhou DEYING MOLD is a plastic mold manufacturer that specializes in manufacturing and processing injection molds. It also provides plastic product processing services, high-speed milling external processing services, and we pay great attention to the quality of molds.

MB/Wechat/Whatsapp:+0086-13456489912

sophiemould@foxmail.com