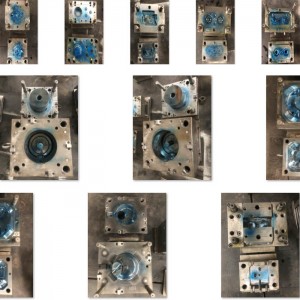

With the improvement of the quality of life, consumers’ mentality has shifted from the most basic life needs to a nutritious and healthy lifestyle. This makes it possible for the juicer to become more popular. DEYING MOLD conforms to the market trend and provides the design of the juicer mold and produce them.

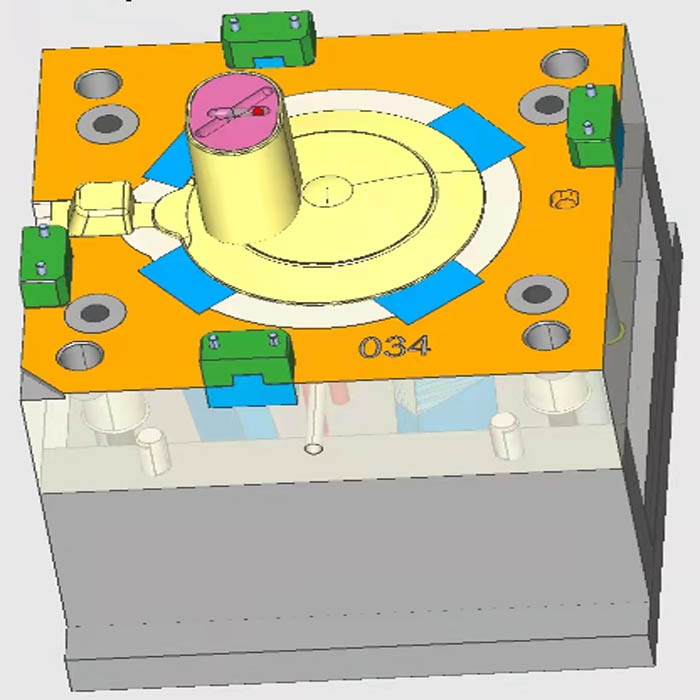

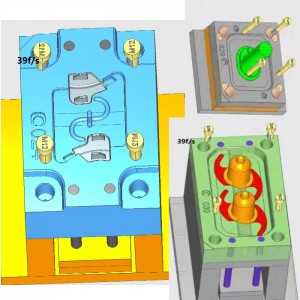

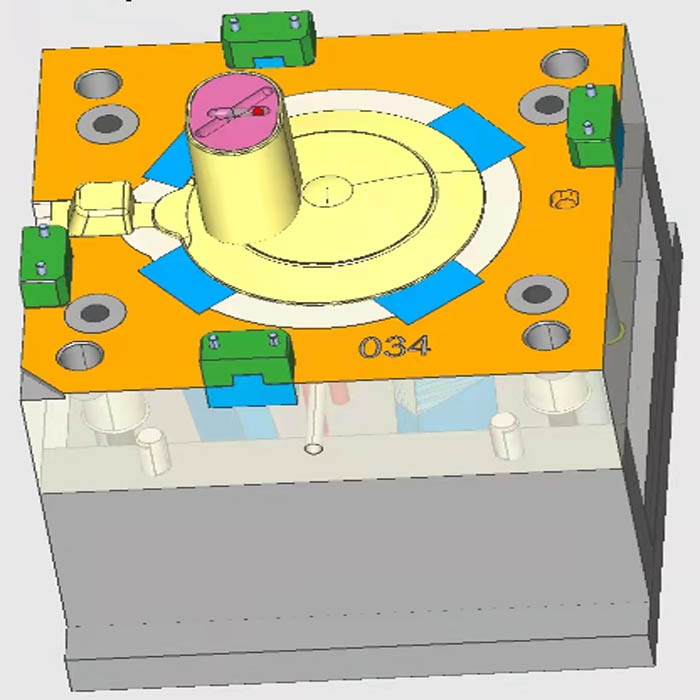

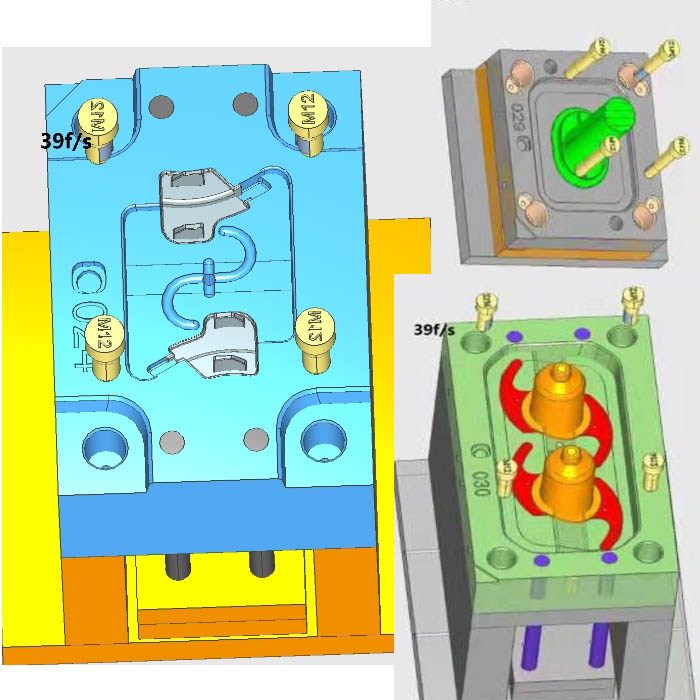

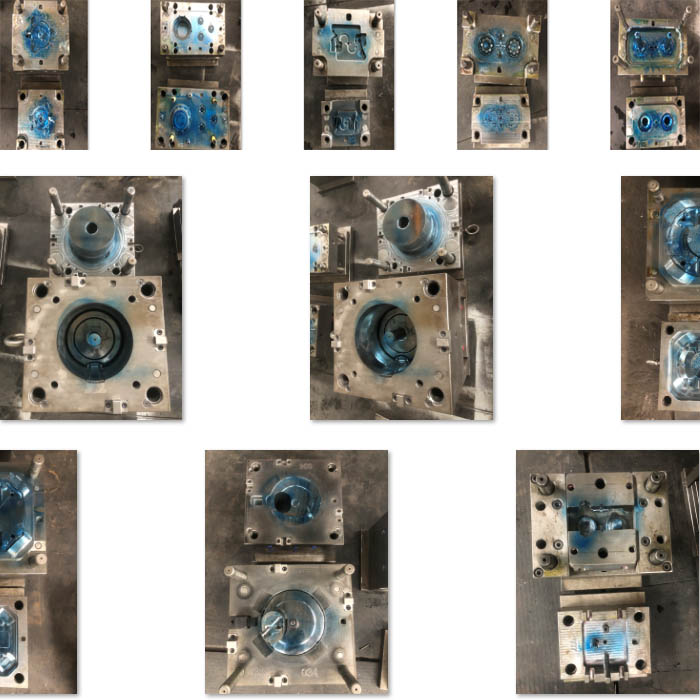

How can I make a mold for an injection molding juicer? First, select the right steel material for the mold base and the mold core cavity. In addition, you must use high-hardness steel as the mold base, and then select the appropriate mold standard parts. A good plastic material filling system requires special hot runner system assistance. Forming, and to ensure that the cooling system achieves the best results. For injection molds, Taizhou DEYING MOLD is a plastic mold manufacturer that specializes in manufacturing and processing injection molds. It also provides plastic product processing services, high-speed milling external processing services, and we pay great attention to the quality of molds.

MB/Wechat/Whatsapp:+0086-13456489912

sophiemould@foxmail.com

-

disposable thin wall Rectangle Compartment tran...

-

plastic injection Baby bath mold child bathtub ...

-

food grade yogurt thin wall Bucket Mould HDPE P...

-

oval 1000ml Lunch box moulding 3-compartment Hi...

-

Factory Direct Sell Fruit and Vegetable Juicer ...

-

China plastic injection kids Children toy mould...