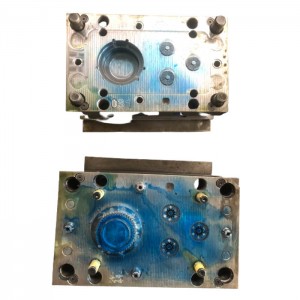

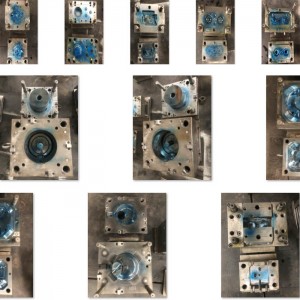

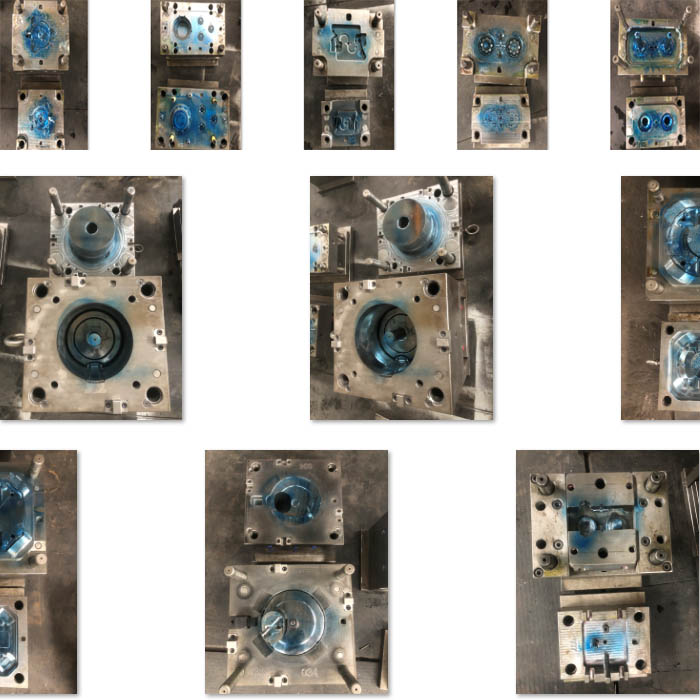

DEYING produces injection molds with many years of experience in processing and production, and can be customized according to needs. The service is thoughtful, the price is reasonable, the quality is reliable, and it supports wholesale and retail. For details, please inquire.

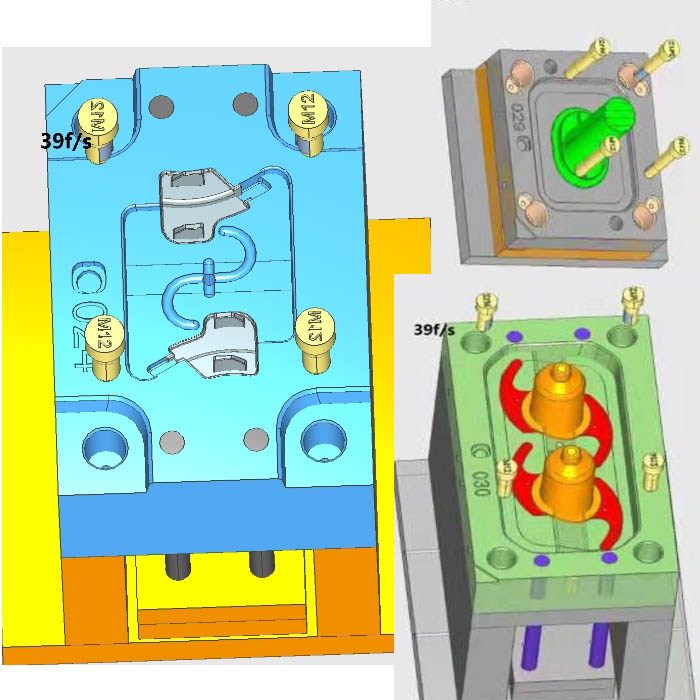

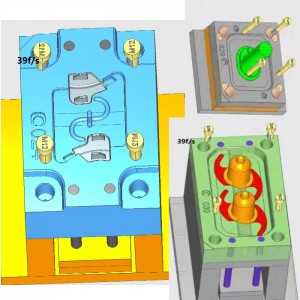

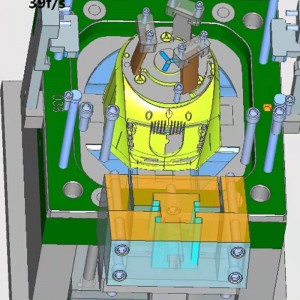

The juicer mold is injection molded. The so-called injection molding is the plastic material in the barrel of the injection molding machine through external heating and the shear heat generated by the rotation of the screw to plasticize the resin material into a melt, and then apply a certain pressure , The product produced by injecting the melt into a cavity with a certain shape after cooling and shaping is injection molding.

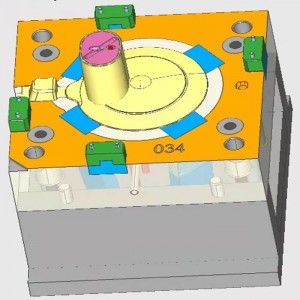

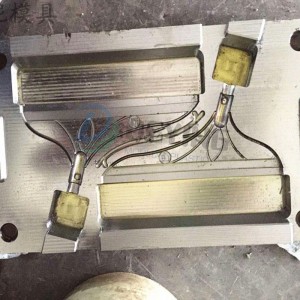

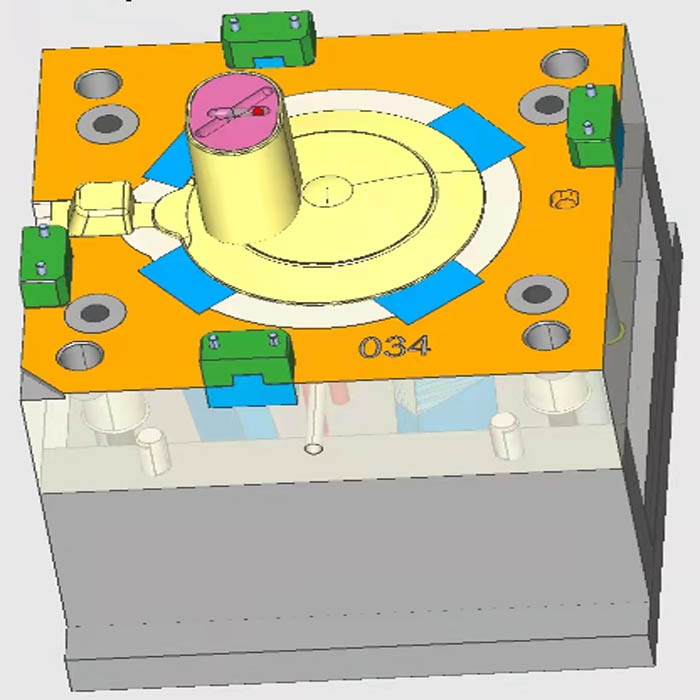

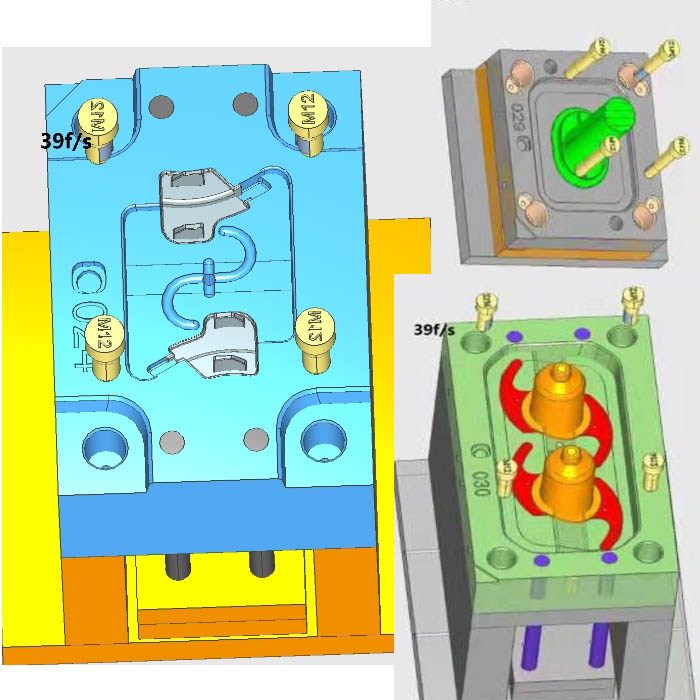

How can I make a mold for an injection molding juicer? First, select the right steel material for the mold base and the mold core cavity. In addition, you must use high-hardness steel as the mold base, and then select the appropriate mold standard parts. A good plastic material filling system requires special hot runner system assistance. Forming, and to ensure that the cooling system achieves the best results. For injection molds, Taizhou DEYING MOLD is a plastic mold manufacturer that specializes in manufacturing and processing injection molds. It also provides plastic product processing services, high-speed milling external processing services, and we pay great attention to the quality of molds.

MB/Wechat/Whatsapp:+0086-13456489912

sophiemould@foxmail.com