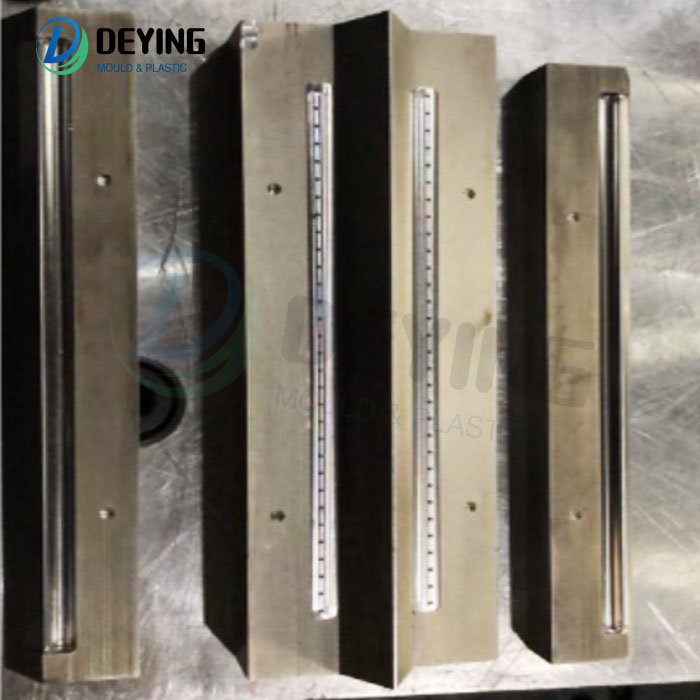

Melt blown cloth is the "heart" of masks, so meltblown die head molds are also used to produce melt blown cloth, which is also called melt blown cloth nozzles or spinnerets in the industry. The melt blown cloth mold is made of YK30 (SK3) carbon tool steel and other steel materials. In the die of meltblown cloth, the diameter of the spinneret is very small, mostly 0.1-0.3mm, with a pitch of 0.6-0.7mm. For example, a 550mm die has close to 1000 holes, and the 0.2mm hole is vertical. Degree is the key, using laser perforation, the precision is higher.

Factory direct supply of non-woven meltblown mold

This mold is a precision mold with a hole diameter of 0.2 wire, and the sprayed polypropylene wire can meet the requirements of medical disposable mask N95 mask.

In terms of mold material, mold design and precision, our mill has the following advantages:

1; Our mold materials are not available on the market, and the mold processing technology and abrasive tool processing are all technical experience for many years.

2; Mold design is the key, which determines the spinning technology of meltblown equipment. Our mold design and precision can ensure that your meltblown is not drawn, waste, and even meltblown.

3; The polypropylene filament sprayed by our mold can guarantee to meet the requirements of medical disposable mask N95 mask

Melt blown cloth mould

The melt-blown production line uses synthetic polymers as raw materials, which are melt-spun and directly formed into a web to form a performance melt-blown non-woven fabric (melt-blown fabric), which is used in filter materials, insulation filling materials, and sanitary materials (such as masks, etc.) , Wipe materials, etc.

Due to the current shortage of masks in the market, melt blown cloth, the core raw material of masks, can no longer meet market demand. Some qualified domestic enterprises have begun to switch to melt blown cloth production, which has stimulated the market's demand for melt blown cloth production line related equipment.

The core raw material of masks---melt blown cloth production process is: raw material---->melt extrusion---->filtration (melt blown cloth change screen filter) ---->metering (melt blown cloth melt Pump)---->air heating and compression---->melt blowing---->netting---->rewinding.

Our company is a professional equipment supplier that provides melt-blown cloth production lines and various parts. Products include but are not limited to extruders, melt pumps, heating pipes, melt-blown cloth molds, melt-blown cloth winders, etc.

Our company’s melt blown cloth molds are all processed by imported high-speed processing equipment. The holes produced have no oblique holes. The hole walls are smooth and do not need to be polished. The verticality and straightness are very good. Wire and broken wire cause serious phenomenon of "material point" floating wire, which is resistant to pressure, corrosion and sufficient mechanical strength.

MB/Wechat/Whatsapp:+0086-13456489912

sophiemould@foxmail.com