Manhole cover molds are widely used in urban roads and are indispensable supplies in people's lives. The manhole cover mold is a traditional road equipment, which has always occupied a major position in manhole covers, etc. However, in recent years, with the design and production of more and more new materials of manhole covers, the manhole cover mold has received unprecedented severe impact. The main reason is It is due to some shortcomings of the manhole cover mold itself. The manhole cover mold has a good anti-theft effect, but the disadvantage is that it is too bulky, and the manhole cover mold must be made first. After construction, the base is fixed by concrete and the groove opening is closed. Only the upper cover can be opened and closed, and cannot be easily removed. The above reasons have hindered the development of the manhole cover mold. If the manhole cover mold is not eliminated in the future development, it must continue to make progress, develop new technologies, overcome its own shortcomings, and seek its own development.

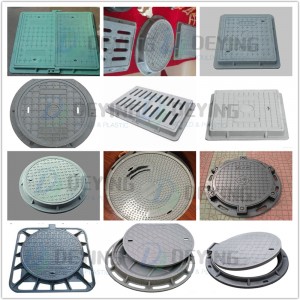

The manhole cover mold can be used in city construction tap water, municipal sewage pipeline inspection wells, heating, gas inspection wells, postal, telecommunications, communication optical cable pipeline wells, power pipeline wells, street lamp wells, fire wells, various valve wells, and anti-corrosion projects. , Rainwater well grate, open ditch cover plate, and can be manufactured according to the special needs of users.

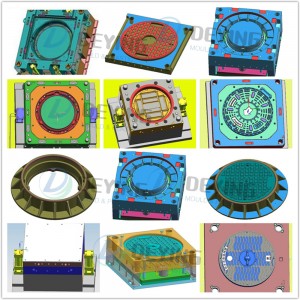

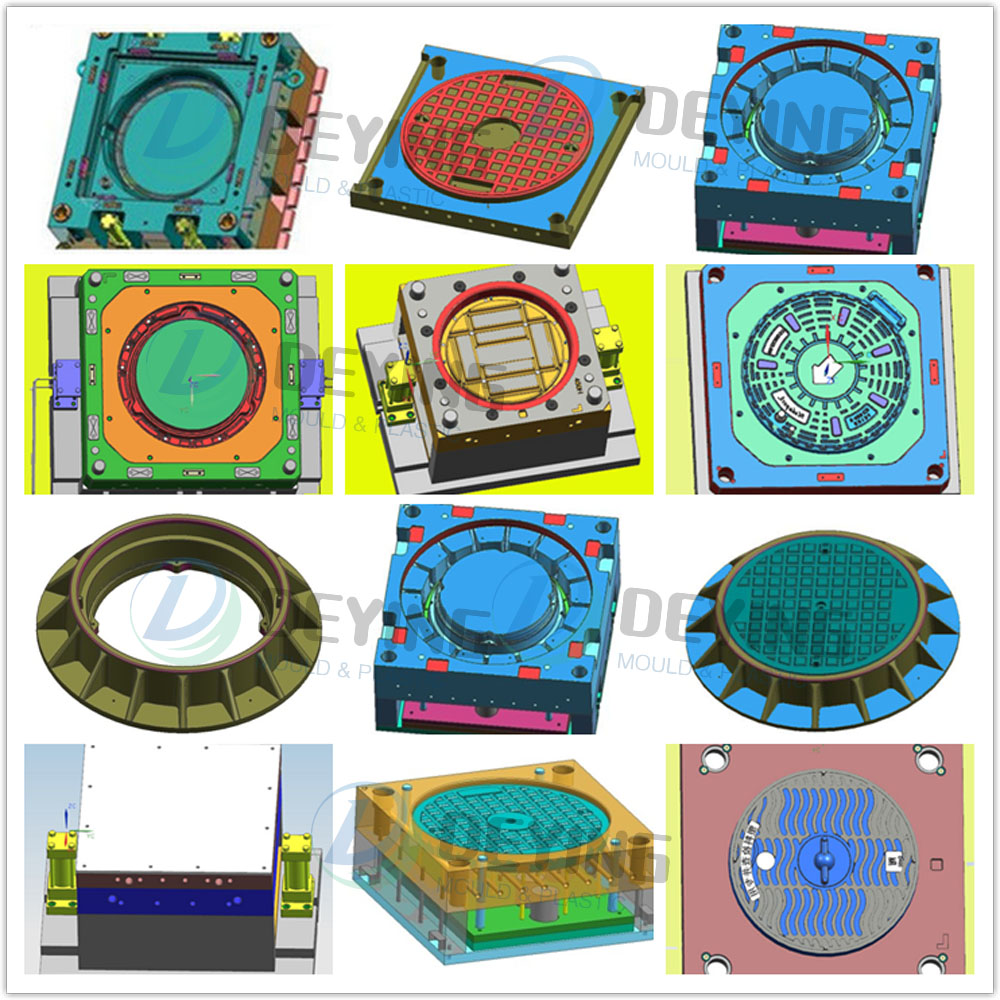

The types of manhole cover molds are: cement round manhole cover mold, county municipal manhole cover mold, inspection manhole cover mold, cement water manhole cover mold

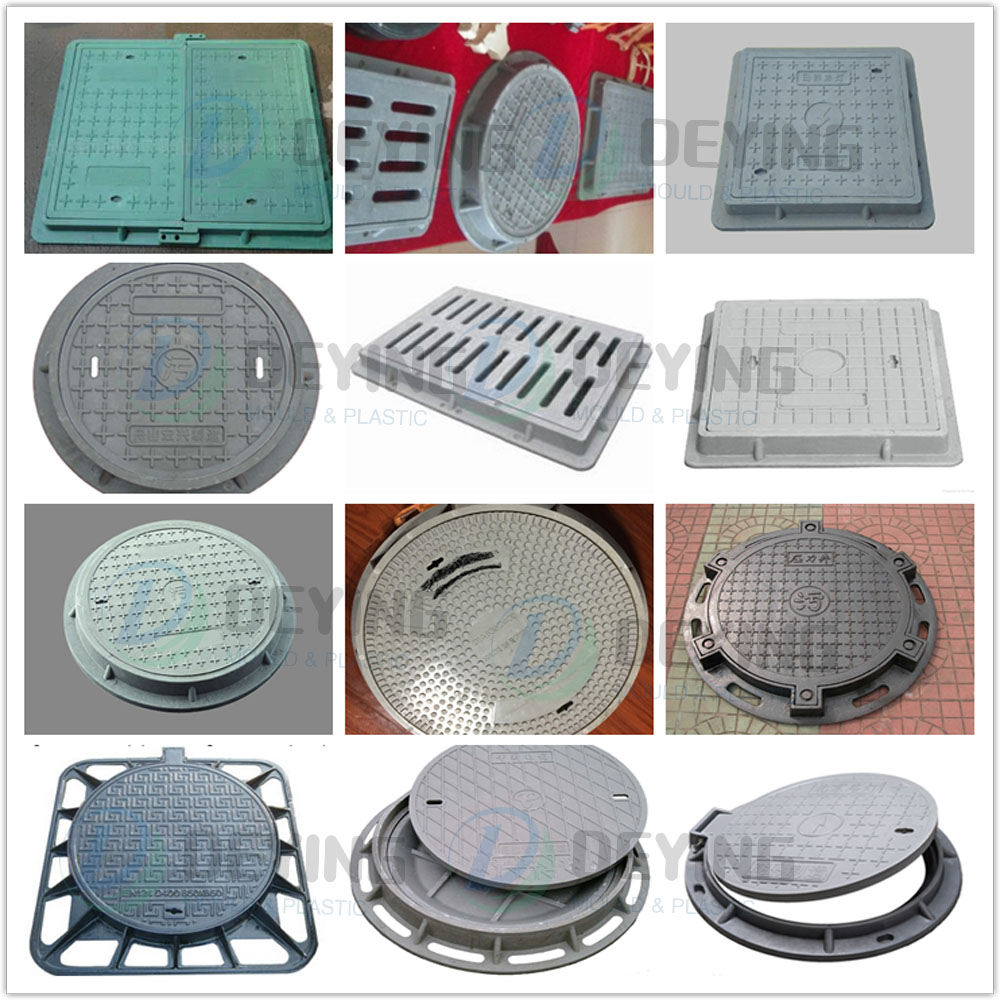

In recent years, composite manhole covers have become one of the important equipment for urban construction! The manhole cover mold avoids some of the defects of traditional cement manhole covers, and is safer and more convenient to use! Since the composite resin manhole cover has become a new manhole cover material, the life of the resin manhole cover has always been the core content of everyone's attention. In order to ensure the service life of the composite resin manhole cover, the manhole cover is divided into two: "manhole cover bottom plate" and "manhole cover surface cover plate", which are produced separately and then combined into one.

In view of the practical functions of the resin manhole cover, the materials are technically targeted to prescribe prescriptions. For the resin manhole cover material, we uniformly select new composite resins suitable for high, medium and low temperature areas, and the material has good toughness. In principle, no brittle materials are used. When brittle materials are crushed by heavy vehicles, they are prone to cracking. The water vapor in the well evaporates and the cracked materials are easily absorbed. After the materials absorb water and hydrolyze, the service life of the product is greatly reduced. In addition, in recent years, a layered composite manhole cover uses unsaturated polyester resin as the matrix material, glass fiber as the reinforcing material, and supplemented by a certain rigid material. The structure adopts the pot bottom structure, the bottom tensile material is evenly stressed; the material is divided into upper and lower layers, and the upper part is made of wear-resistant and aging-resistant materials, and the product has a long service life.

The lower part is reinforced by continuous glass fiber, which can make the manhole cover have sufficient load-bearing capacity without any reinforcement by steel bars. It is a material manhole cover with better comprehensive performance among several composite material manhole covers. The layered composite manhole cover has the advantages of high surface hardness and slightly higher brittleness; anti-theft and high carrying capacity!

MB/Wechat/Whatsapp:+0086-13456489912

sophiemould@foxmail.com