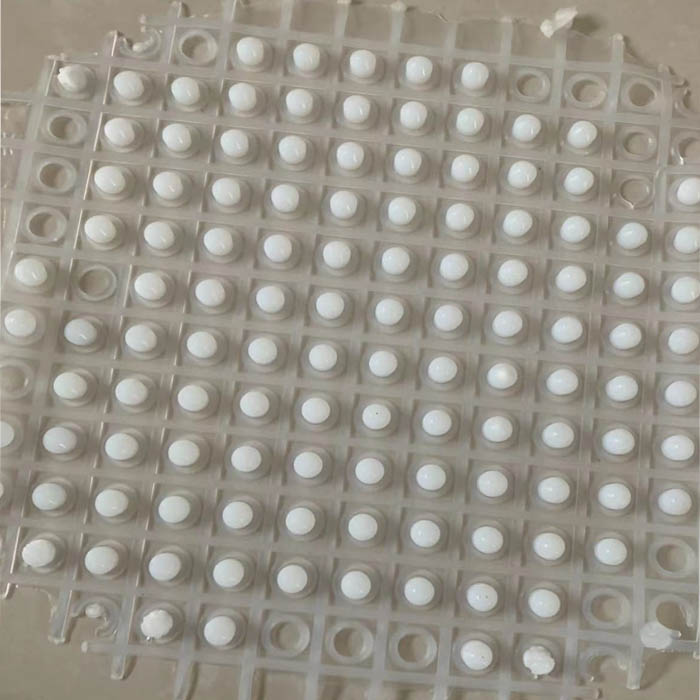

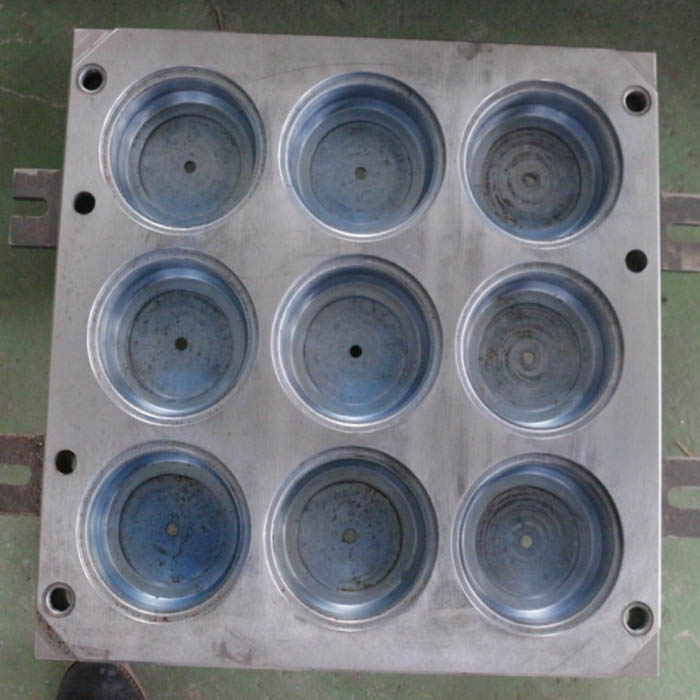

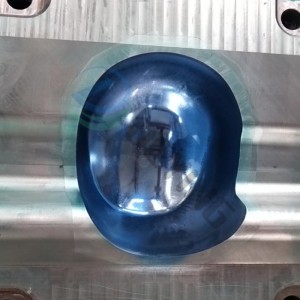

Flat vulcanization is a widely used process method for molded rubber products. Many rubber products are produced on flat vulcanizers. DEYING produces various rubber product molds, such as O-ring rubber molds, piston cups, industrial gasket rubber molds, and electrical Connectors, rubber sheets, shock-absorbing springs, medical products, bottle stoppers, drainage devices and other rubber product molds.SBR NBR EPDM Vulcanized Gasket Customized production, welcome to contact.

The product made from rubber as raw material and vulcanized under high temperature and high pressure with a mold is called a rubber model product. The larger one has automobile tires, and the smallest one has a lighter sealing ring with a diameter of only 50 millimeters. The mold material, dimensional accuracy, exhaust and mold opening difficulty, etc. all directly affect the quality, labor intensity, and production efficiency of rubber products. At the same time, the selection of mold material, heat treatment and other manufacturing processes, as well as the quality of mold assembly, directly affect the service life of the mold. Therefore, when designing the mold, firstly, we should carefully analyze and study the characteristics of the shape and structure of the rubber parts, and use this as a basis to select and design a reasonable mold structure, reasonable material and heat treatment process to meet the requirements of rubber products and the use of molds. It is required that the mold is easy to open after vulcanization, which can provide the production efficiency and the service life of the mold, thereby improving the economic benefit.

MB/Wechat/Whatsapp:+0086-13456489912

sophiemould@foxmail.com

-

Round Telecom Composite Manhole Cover mould Pro...

-

plastic injection Maintenance free Dry charged ...

-

taizhou Household commodity plastic injection a...

-

High quality compression SMC kitchen sink mould

-

Special Forces Ballistic Protection Helmet mould

-

Composite Cable Trench Cover Plate mould FRP Ma...