BMC Mould> Compression Mould / BMC Mould

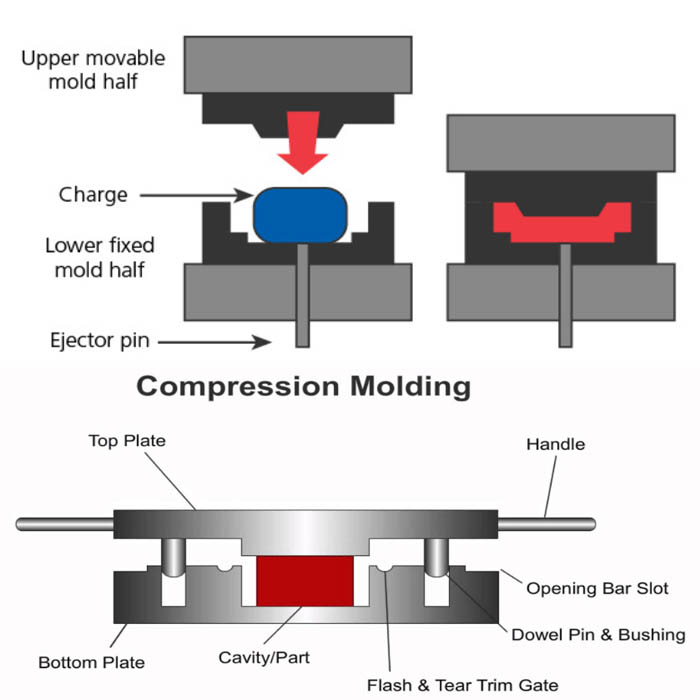

BMC is the abbreviation of Bulk Molding Compounds, that is, bulk molding compound. It is often referred to as unsaturated polyester agglomerate molding compound in China. Its main raw material is a dough-like prepreg that is fully mixed with GF (chopped glass fiber), UP (unsaturated resin), MD (filler calcium carbonate) and various additives.

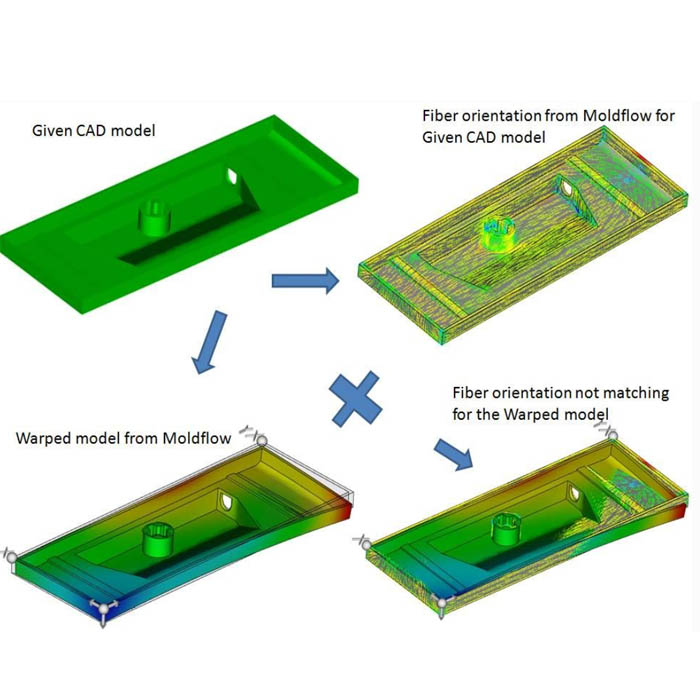

BMC is a kind of thermosetting plastic, mixed with various inert fillers, fiber reinforced materials, catalysts, stabilizers and pigments, etc. According to the final application, the compound can be formulated to achieve strict dimensional control, flame retardancy, and high dielectric. Strength, corrosion and stain resistance, and color stability. The excellent flow characteristics of BMC molds make it ideal for various applications that require precision and dimensional accuracy. The material is available in a variety of colors. BMC has many unique characteristics, such as high hardness, light weight, corrosion resistance, UV resistance, good insulation, and excellent thermal properties, which make BMC more satisfactory than thermoplastics. At the same time, since many components can be molded simultaneously with these components, no post-processing is required, which is more economical from a production point of view. Currently, BMC molds have been used in areas such as automobiles, energy, electrical appliances, catering services, household appliances, optical instrument components, industrial and construction supplies.

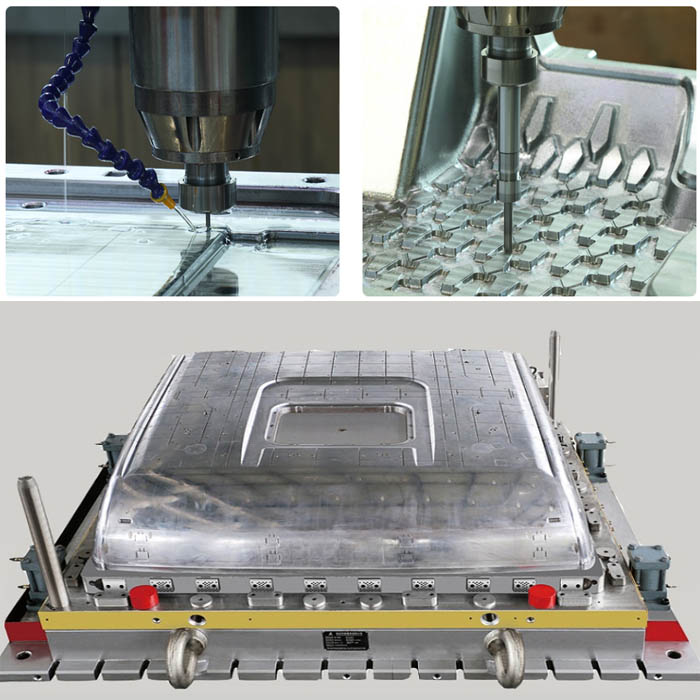

DEYING Mould is a BMC mould supplier. It is engaged in the design and manufacture of BMC moulds. It has a matching test mould assembly line for BMC moulds and has developed many BMC products, such as BMC car tail lamp covers, BMC electrical boxes, BMC meter boxes, BMC manhole covers, etc . BMC mold is suitable for compression molding or injection molding. Because of its short glass fiber characteristics, this BMC composite material is more suitable for complex components, such as electrical equipment, automotive components, electrical energy parts, etc. Some BMC products require high precision , The quality and appearance requirements meet the A-level surface requirements, the construction period is completed on time, and the quality and construction period are unanimously praised by the OEM.

MB/Wechat/Whatsapp:+0086-13456489912

sophiemould@foxmail.com

Post time: Jul-08-2021