Our friends often ask the editor about SMC materials, SMC molds and other related questions. The editor cannot answer them one by one. We can only briefly introduce the characteristics of SMC materials and the planning of SMC molded products through this article. , The content is as follows:

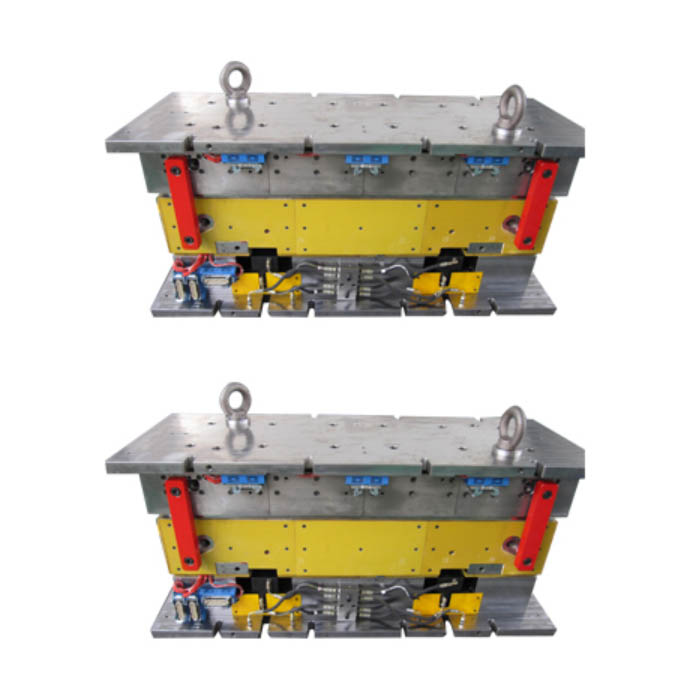

SMC mold molding product planning:

Regarding the planning of SMC molded products, it is not only necessary to determine the shape and structure of the finished product according to the application quality requirements of the SMC product and the working condition of the load, but also to carry out each procedure and each influencing factor in the process according to the practice of molding production. Necessary analysis and trade-offs are necessary to make the determined structure of the finished product meet the technical requirements of molding.

The impact of the SMC finished product planning structure on the future production process mainly reflects the difficulty of mold planning and the implementation of technical conditions in the molding process. The ideal structure of the molded product should be able to easily plan and produce the molding mold, and can smoothly produce an excellent SMC molded product.

The external shape planning of the SMC finished product is the basic link of the SMC molded product planning.

External shape of SMC finished product: The external dimensions and shape of the SMC molded product are obtained under the tolerance of the molded parts. The simpler the external shape of the finished product, the easier it is to process and manufacture the molded parts; the lower the precision requirements for the external dimensions of the finished product, the processing accuracy of the molded parts will decrease accordingly. Therefore, when deciding on the external structure of the finished product, it should be as simple as possible on the premise of satisfactory application quality.

In the planning of SMC molded products, full attention should be paid to the influence of the shape of the finished product on the technicality. For example, in many situations, the inevitably demanding grooves, platforms, and heights in the shape and structure will not only complicate mold production, but also affect the yield due to the inversion and bending of the molding material during molding. Therefore, in the SMC finished product shape planning ( Especially for high-strength finished products), it is necessary to minimize the flow direction reversal bending of the molding material during the molding process. Because the finished product has sharp corners, during the molding process, the SMC molding material is blocked by the sharp corners, resulting in uneven material flow. Often the sharp corners cause resin accumulation or lack of material, looseness, and simply cause uneven pressure on the finished product. After demolding, the finished product will be warped and deformed due to the existence of internal stress. In addition, disadvantages such as poor surface quality and reduced strength of the finished product will also occur.

Therefore, when planning the SMC molded product, the sharp corners should be rounded, and the radius should be as large as possible without affecting the appearance and application requirements.

I believe that seeing this, friends have a clear understanding of SMC materials and SMC products. I hope the above content is helpful to everyone, thank you for browsing!

SMC material characteristics:

1. Superior anti-corrosion function;

2. The advantages of light weight and simple and flexible project planning;

3. Its mechanical function can be comparable to some metal materials) It has the characteristics of good planability, high strength, waterproof, corrosion resistance, and resistance to pollution.

Therefore, the characteristics of the glass fiber reinforced plastic environmental protection air conditioner shell made of SMC composite materials are:

1. Light weight;

2. High specific strength;

3. Features of impact resistance.

The density of the glass fiber reinforced plastic environmental protection air conditioner casing is about 1/4 of the density of steel and 2/3 of the density of aluminum, but its strength is very large. Its tensile strength is close to that of ordinary carbon steel. The bending strength and bending elastic modulus are common plastic profiles. 8 to 10 times of that. Acid and alkali resistance, corrosion resistance, and aging resistance. SMC materials are excellent corrosion resistance materials. They have good resistance to acids, alkalis, salts, some organic matter, sea water and humidity. They also have the function of resistance to the effects of microorganisms. Its service life is long.

MB/Wechat/Whatsapp:+0086-13456489912

sophiemould@foxmail.com

Post time: Jul-01-2021