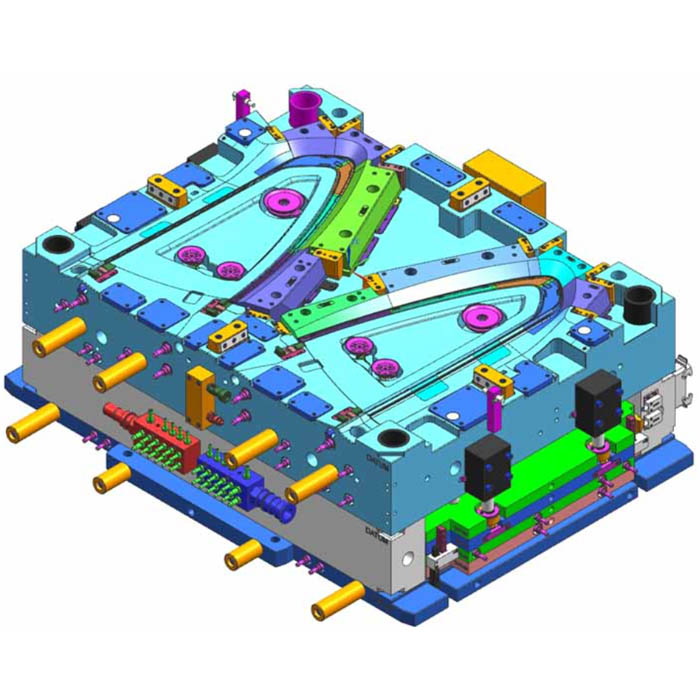

The manufacturing of many products is a very important part of the early mold design. Imagine if the product mold has a design flaw, then the product is naturally flawed. Today, the editor of DEYING Mould came to talk to my friends briefly about several key points of SMC mould design. The details are as follows:

SMC mold design and manufacturing points

The main points of SMC mold design and manufacturing cover SMC mold product classification, processing accuracy, demoulding, cutting edge, fillet, heating method, mold material, surface treatment and other common problems, etc. Some small details of SMC mold design are for everyone It is very important. This article provides a comprehensive reference for mold manufacturers to make SMC molds.

1. SMC mold ejection plate thickness

The thickness of the ejector plate should be determined according to the size, shape and weight of the mold, and its thickness is generally not less than 30mm, otherwise the ejector plate deformation and other problems will easily occur.

2 SMC mold heating hole distribution

SMC mold heating hole distribution requirements are that the heating hole should not be too close to the cavity, nor too far away, it is best to keep 40~80mm; the distribution of heating holes should be thin in the middle and dense at both ends; if the SMC mold uses electric heating, the heating holes That is, the number of electric heating tubes is preferably a multiple of 3 to facilitate the connection of electricity, and the electric heating tubes at both ends must be a certain distance beyond the edge of the cavity; d) The distribution of heating holes should follow the shape of the mold.

3. SMC mold side drawing mechanism

When the side of the product has holes or convex and concave sides, a side-shaped core must be used to meet the requirements of the product. The side core must be drawn out before the product is demolded. SMC mold should avoid side core pulling mechanism as far as possible. If side core pulling cannot be avoided, make core pulling as short as possible.

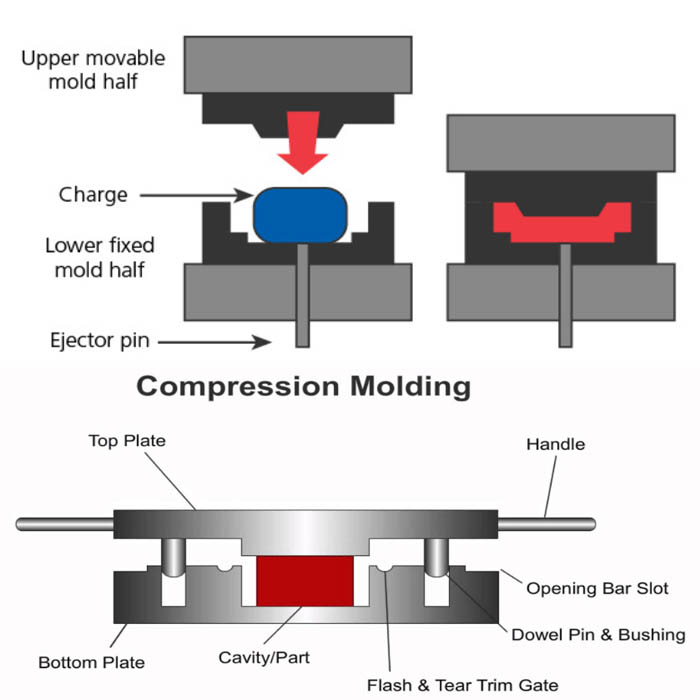

4. SMC mold ejection method

The selection of SMC mold ejection system is mainly to separate the product from the mold when the press is turned on after the product is formed, so as to facilitate the removal of the product. The ejector rod is located in the SMC mold and is driven by some mechanical (or hydraulic) means. These systems include hydraulic systems and mechanical action systems. There are two types of commonly used hydraulic systems, one is the hydraulic system inside the press, and the other is the hydraulic system that is separately connected to the ejector plate on the mold. Among them, when the oil cylinder is installed on the mold ejector plate, the ejection imbalance will often occur. The solution is to connect a gear oil separator. The above two systems are very suitable and have good effects. Each production unit can choose a suitable ejection method according to its actual situation.

MB/Wechat/Whatsapp:+0086-13456489912

sophiemould@foxmail.com

Post time: Jul-01-2021