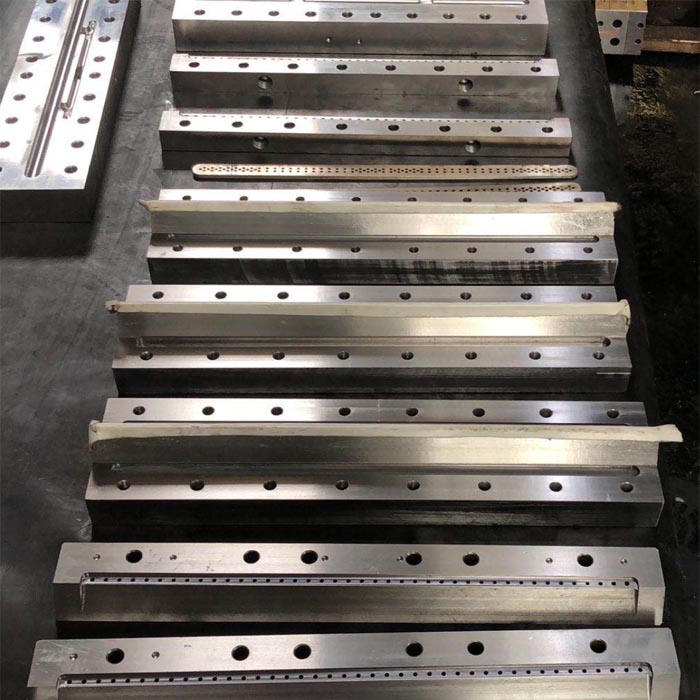

Spinneret micro-hole processing, using ultra-precision ultrasonic tool holder, to deal with 4 major pain points

Can filter bacteria and prevent the spread of viruses

Meltblown cloth is called the "heart" of masks!

Then why is the spinneret called the "heart" of the "heart"?

Because the production of melt blown cloth is formed by blowing high-speed hot air from the micro-holes of the spinneret: the viscous polymer melt is transformed into a small stream with a specific cross-section through the micro-holes, and solidified by the solidification medium. achieve.

Therefore, the spinneret is the core of the melt blown cloth production line, and the quality of the melt blown cloth is closely related to the uniformity and stability of the spinneret discharge, and it has high requirements for its micro-hole processing!

However, in stainless steel materials, there are only 2-3 micropores of the thickness of the hair, and there are multiple (aperture diameter Φ0.1-0.3mm, spacing less than 1mm), the difficulty can be imagined!

Spinneret maintenance

There has the following methods:

1. Regular maintenance (grinding/polishing the surface of the spinneret, how to clean the spinneret, and recalibrate the pores);

2. Repair damaged capillaries or spinning plates;

3. Correct and optimize the spinneret, increase how to clean or plug the spinneret hole;

After the spinneret is repaired and maintained, the spinneret can be put into a new round of use. How to clean the spinneret.

MB/Wechat/Whatsapp:+0086-13456489912

sophiemould@foxmail.com

Post time: May-27-2021