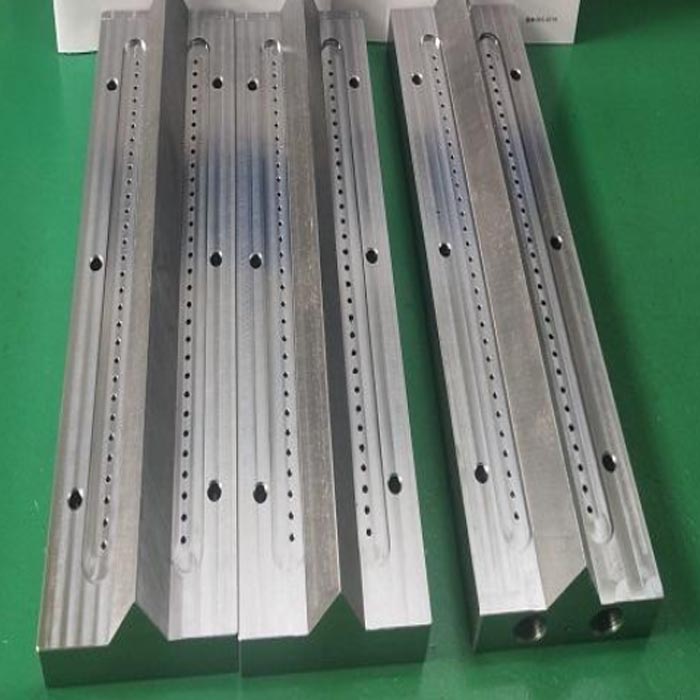

The mask non-woven fabric is made of polymer chips with high melt index, which are extruded and heated and melted into a high-temperature melt with good fluidity. The melt will be sprayed from the spinneret using high-temperature, high-speed hot airflow. A production process in which the thin stream is blown into very fine fibers, gathered into a fiber web on a receiving device (such as a web forming machine), and bonded to each other to form a cloth using its own waste heat. However, the spinneret using the melt blown line is easy to be blocked, which affects the quality of the melt blown cloth.

What should I do if the spinneret is clogged? There are actually many ways to clean the plugging of the spinneret, but the one that has little effect on the material of the spinneret is the vacuum high-temperature calcination cleaning. This method effectively avoids the damage and oxidation of the metallographic structure of the workpiece, and maintains the original good quality of the workpiece. Metallic luster. Next, we will introduce the vacuum high-temperature calcination cleaning equipment of the spinneret-vacuum cleaning furnace.

1. The composition of the vacuum cleaning furnace

The vacuum cleaning furnace is mainly composed of a vacuum sealed furnace, a stainless steel electric heating tube heater, a waste collection tank, water, a water ring vacuum pump, a work basket, and a temperature automatic program control system that serves it, a vacuum pump automatic opening and closing system, and water circuits, instruments, etc. composition.

2. Working principle of vacuum cleaning furnace

The vacuum cleaning furnace uses plastic chemical fiber polymer polymer that can be melted at about 300℃, and can be cracked and coked by isolating air above 300℃, and produce a variety of pyrolysis products. Above 400℃, under the condition of a small amount of oxygen and a certain degree of vacuum It can be completely oxidized. Using this feature, first heat the workpiece to about 300°C, so that more polymer on the surface of the workpiece melts and flows into the waste collection tank at the bottom, leaving only a small amount of polymer and ash in the micropores on the surface of the workpiece. At this time, the furnace temperature is raised to 400~500℃ (the temperature can be determined according to the process requirements), and the vacuum pump is turned on, and a small amount of air is introduced to fully oxidize the remaining high molecular polymer to generate carbon dioxide and water. The ash and water vapor floating in the furnace are sprayed and washed by a water spray scrubber and then taken out of the furnace and taken away by the water. During the whole working process, no polluting gas, smoke and ash are discharged indoors, and even a small amount is discharged outdoors. Carbon dioxide, the ash taken away from the water is also very small.

3.the characteristics of vacuum cleaning furnace equipment

1). The vacuum cleaning furnace adopts high temperature resistant sealing ring and does not need water cooling protection. Therefore, the equipment has low heating power, high thermal efficiency, fast heating speed, good temperature uniformity, heater inspection and maintenance, and is more convenient than external heating The heater saves a lot of electricity and water, and overcomes the defects of poor temperature uniformity in the furnace caused by water cooling and poor local cleaning effects.

2). Integrated design of electromechanical and instrument, easy to install. The furnace body is integrated with the control cabinet, which reduces the equipment area and simplifies the on-site installation workload of the equipment. The volumetric equipment using industrial elevators can be easily installed at designated locations without destroying existing buildings.

3). The equipment has complete automatic working performance. As long as the program temperature controller is input to the proposed working program, the equipment can perform automatic cleaning work without manual intervention in the middle, and has the alarm function of over-temperature, lack of items and water cut or low water pressure. .

MB/Wechat/Whatsapp:+0086-13456489912

sophiemould@foxmail.com

Post time: May-27-2021