This article will introduce you some related molding methods, main molding principles and control factors

1. Molding method

Carbon fiber is a fiber material, so the formation process of carbon fiber is the formation of fiber. The fiber forming process is a process of placing pre-mixed or impregnated fiber forming materials in metal form under a certain temperature and pressure to form a composite product.

2. The main forming principle

The inheritance and behavior of the entire thermoset is far more than that of thermoplastics. Chemical reactions always occur during the entire molding process. In the first stage, that is, at the beginning of heating, the material viscosity and low molecular weight show good fluidity. The interaction with the functional group causes some components to crosslink and the fluidity is weakened and the material produces a certain degree of elasticity. When the material is in the gel state, the cross-linking reaction of the molecules will be more complete, changing from the gel state to the glass state. Regarding the glassy material that changes from the gel state, and the resin body presents a shape structure, the molding is completed.

3. Forming factor

The controlling factors formed, commonly known as the "three factors", namely temperature, pressure and time

1) Temperature: This process variable determines the heat transfer state of the mold to the material in the cavity, and has a decisive influence on the melting, flow and solidification of the material.

2) Pressure: Close the mold to make the material more dense, promote the flow of the melt, and balance the pressure generated by the volatilization of small molecules in the mold cavity.

3) Time: also called mold time, to ensure that the cavity has enough time to complete curing.

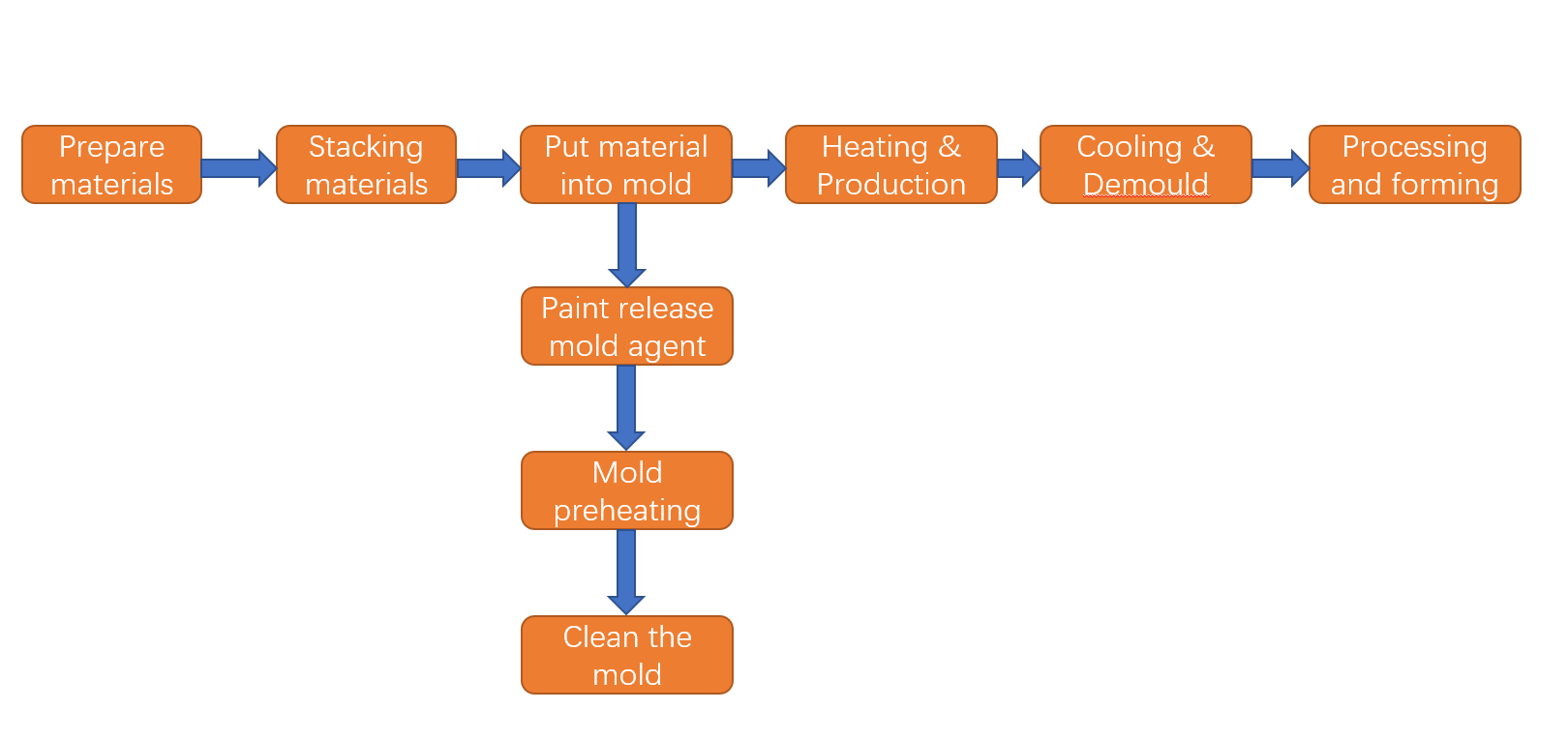

The following is the molding flow chart:

Step description:

1. Clean the mold: clean the resin and debris left in the mold last time, and keep the mold tools are clean and smooth.

2. Mold preheating: heat treatment of the mold.

3. Apply mold release agent: Apply a certain amount of mold release agent to the groove of the mold to prevent subsequent pre-treatment,the molded product and the mold stick together after the heat.

4. Material preparation: prepare the raw materials of the carbon fiber that will be made into the product, and calculate the raw materials,the area of material used, the number of sheets of material used.

5. Stacking: stacking the raw materials layer by layer, and pre-pressing the stacked materials at the same time,It is pressed into a dense entity with a regular shape and a certain quality.

6. Into the mold: Put the stacked raw materials into the mold, and put plastic gas inside at the same time,Bag, mold clamping, put the whole into the mold clamping machine, add a certain constant to the inner plastic airbag Material preparation, stacking, mold feeding, hot pressing, cooling, demoulding, processing and forming ,Apply release agent,Mold preheating,Clean the mold pressure, set a constant temperature, and set a constant time to make it solidify.

7. Cooling and demoulding: cool down the mold for a period of time after the hot pressing treatment for a period of time.Then uncover the mold for demolding treatment.

8. Processing and forming: the product after demolding needs to be cleaned, scraped with a steel brush or a copper brush,Remove the residual plastic and blow it with compressed air to polish the molded product to make the surface is smooth and clean.

MB/Wechat/Whatsapp:+0086-13456489912

sophiemould@foxmail.com

Post time: Jul-23-2021