The four stages and seven precautions for the development of FRP septic tanks are described.

Due to the particularity of raw materials, light weight, high strength, no corrosion, no leakage, good water treatment effect, and convenient construction and installation, only digging and burying can make up for the shortcomings of traditional septic tanks. Its development has gone through four stages:

In the first stage, the product is square, which can be seen as two trapezoids. Although this product is not resistant to corrosion, it has the disadvantage of insufficient sealing.

In the second stage, the product is basically a horizontal cylinder with good compression resistance, but the processing process is complicated and it is difficult to improve and produce.

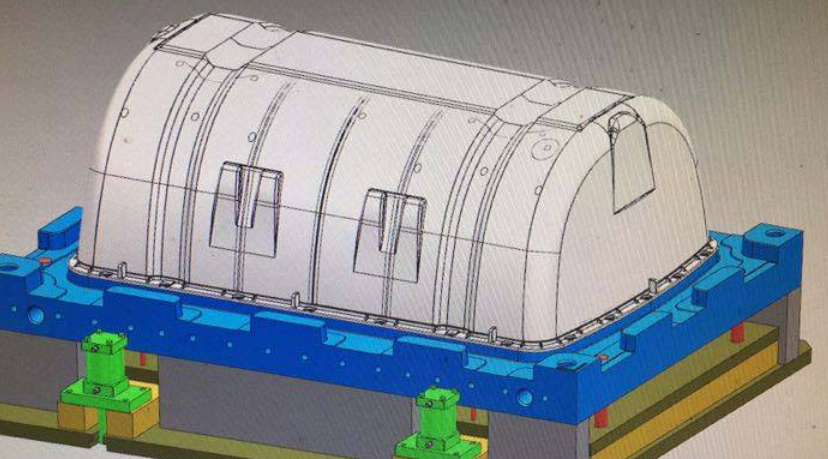

The third stage is a corrugated glass fiber reinforced plastic septic tank, which has good sealing and pressure resistance. This technology has been applied so far.

The fourth stage is the inner corrugated glass fiber reinforced plastic septic tank, which is currently widely used. The product has a smooth cylindrical shape, which reduces the force-bearing area of the product. However, the square steel embedded steel bars are used at a certain distance inside, which is similar to the wave undulation, so it is also called the inner corrugated glass fiber reinforced plastic septic tank.

Precautions on how to construct FRP septic tanks:

1. First, determine the length, width and width of the groove. According to the size of the installed FRP septic tank, the notch is enlarged by 700mm, and the depth is determined by the municipal elevation and the position of the inlet pipe (the distance between the upper wall of the inlet pipe and the tank top is 50mm, and the distance between the upper wall of the outlet pipe and the tank top is 50mm) . Is 100 mm).

2. The ground durability should be greater than 10 tons, otherwise a 100mm thick concrete cushion should be made.

3. When there is groundwater, it is necessary to lay a 100mm pebble layer first, then a 100mm concrete cushion and a 100mm sand cushion.

4. In the absence of groundwater, when the ground surface durability is greater than 10 tons, only 100mm sand pads are needed.

5. The breccia must be removed during backfilling. At the same time, the backfill compaction is also particularly important, which directly affects future use.

6. The depth of the overlying soil layer is greater than 1200mm, and the road load is steam -15. If it is less than 1200mm, it needs to cross the pavement structure. If the load is greater than 15 tons, pavement construction is required. The manufacturer can provide a road structure reinforcement map.

Post time: Mar-10-2021