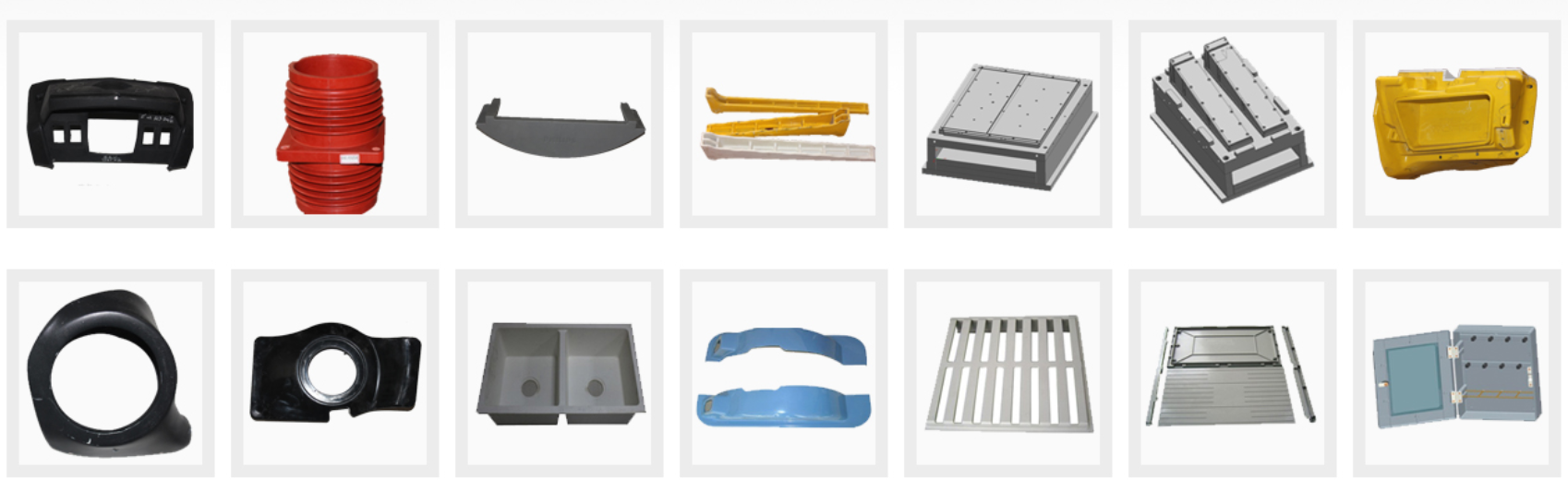

The SMC mold is a combined plastic mold for compression molding, extrusion, injection, blow molding and low foam molding. It mainly includes a concave mold combined substrate, a concave mold component and a concave mold combined card board. The concave mold of the variable cavity is a convex mold with a variable core composed of a convex mold combined base plate, a convex mold component, a convex mold combined card board, a cavity cut-off component and a side cut combined board. Coordinated changes of mold convex, concave mold and auxiliary molding system. Series of plastic parts of different shapes and sizes can be processed. In the plastic processing industry, it is matched with plastic molding machines to give plastic products a complete configuration and size tool.

Due to the wide variety of plastics and processing methods, and the complex and simple structures of plastic molding machines and plastic products, the types and structures of plastic molds are also diverse.

I have made a unique summary of the layup of SMC FRP molds, and provide thoughtful service to our customers, improve our theoretical knowledge and practical operation capabilities, and let our customers simply understand SMC FRP molds.

Laying steps of SMC FRP mold:

One: After the SMC glass fiber reinforced plastic mold gel coat starts to solidify, it can start to lay up. Laying process can not be too fast, usually 2-3 layers of glass fiber cloth or glass fiber felt a day.

Two: A certain amount of mold resin should be used for paving. The function of this resin is better than that of ordinary resins. During the laying process, the workers must mix glue, that is, add an accelerator and a curing agent to the resin.

Three: Use a glue tool to apply glue, spread a layer of glass fiber fabric and apply a layer of glue, and use an iron roller to flatten the fabric to remove air bubbles and make the glue even. After reaching the specified thickness, the laying is complete.

Under normal circumstances, the thickness of the mold should reach 3-5 times the thickness of the product. So the laying time is usually longer, it can continue for 6-7 days.

Post time: Mar-10-2021