Details determine success or failure, and I believe my friends will all understand this truth. This is especially true in industrial production. This is especially true for the production of SMC FRP molds, otherwise the slightest error will be too far, and the impact will be the entire product quality in the later period. Today, the editor of DEYING Mould is here to give my friends a brief introduction to the details that need to be paid attention to in the manufacture of this kind of FRP moulds, as follows:

1. The silicone rubber material is in a fluid state before use, with good fluidity and filling properties. After being formulated, a rubber elastomer is formed through cross-linking reaction, which can have greater elastic deformation, and the water in the original mold has no effect on its cross-linking reaction. The cross-linked silicone rubber has good sealing performance and does not adhere to the original mold and glass fiber reinforced plastic. Using it as the surface layer material of the glass fiber reinforced plastic mold can not only produce the shape of the work with high quality, but also ensure smooth demoulding. However, the silicone rubber cross-linked body is easy to deform, and when used as a mold, a support carrier is required. It can be used as the carrier material of the mold by taking advantage of the easy forming characteristics of FRP.

2. The specific method for making FRP molds is: apply the prepared silicone rubber to the original mold several times, and the silicone rubber layer should be more than 1mm behind (note the details, not too thick).

3. After the silicone rubber is cross-linked, a glass fiber reinforced plastic layer with a thickness of about 3mm is formed on the silicone rubber.

4. After the glass fiber reinforced plastic is cured, cut the overall mold along the divided unit blocks, and pay attention to cutting the glass fiber reinforced plastic layer and the silicon rubber layer at the same time when cutting. The connecting ribs are made between the unit blocks, and a slot should be set at the connecting ribs to ensure that the unit block molds are combined into a whole through the connecting ribs.

5. After the above work is completed, demould the glass fiber reinforced plastic unit block, then remove the silicone rubber layer, and put the removed silicone rubber block back into the glass fiber reinforced plastic unit mold immediately.

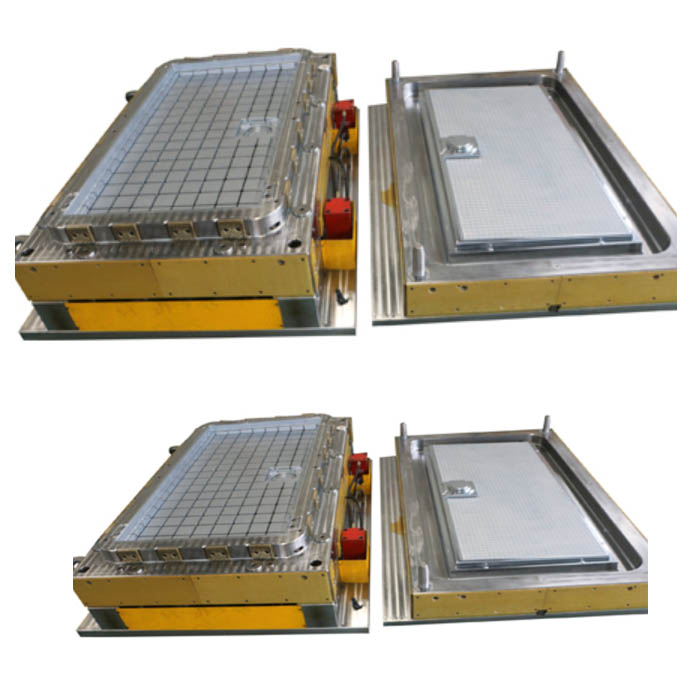

In general, the main process of making FRP molds is as follows: Dust removal from the original mold → Silicon rubber preparation → Silicon rubber layer production → FRP layer production → Die segmentation → Connection rib production → Demolding and assembling the mold. Every link needs to pay attention to details to ensure the results of the entire FRP mold.

Summary: The above is the entire content of "Details determine success or failure: FRP molds need to pay attention to details" compiled by DEYING mold editor for friends. I hope it will be helpful to friends. If you need more detailed information about the production process of SMC FRP molds , Please pay attention to the update of this site in time.

MB/Wechat/Whatsapp:+0086-13456489912

sophiemould@foxmail.com

Post time: Jul-01-2021