Compression molding process:

(1) Feeding: Add a specified amount of material to the mold as needed, and the amount of feed directly affects the density and size of the product. If the amount of feed is large, the product will have thick edges, poor dimensional accuracy, difficult to demold, and may damage the mold; if the amount of feed is small, the product will not be tight, the gloss will be poor, and even cause shortage of materials and waste products.

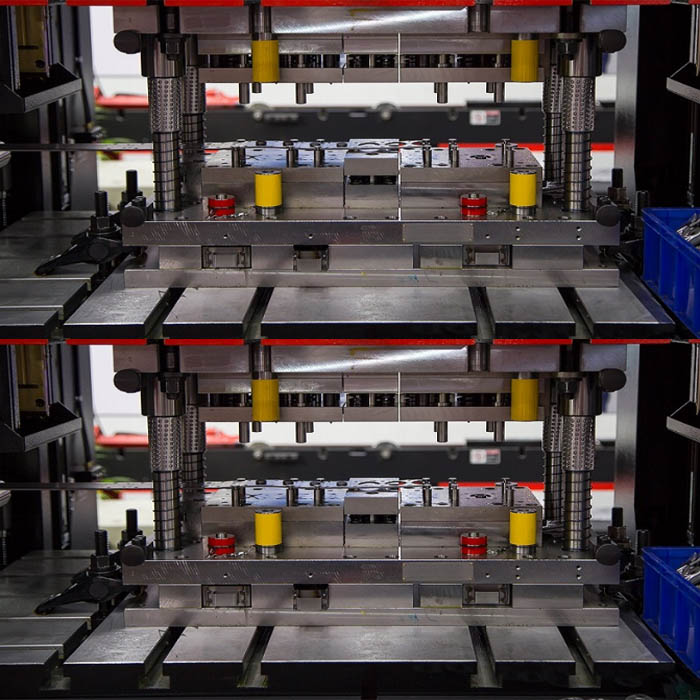

(2) Mold closing: even if the male and female molds are closed after feeding. When closing the mold, use fast speed first, and change to slow speed when the male and female molds are in quick contact. The quick first and slow operation method is beneficial to shorten the non-production time, prevent the mold from scratching, and avoid the raw material in the mold cavity from being carried out by the air due to the rapid clamping, and even the displacement of the insert and the destruction of the molding rod. After the mold is closed, the pressure can be increased to heat and pressurize the raw materials.

(3) Exhaust: When molding thermosetting plastics, moisture and low-molecular substances are often released. In order to remove these low-molecular substances, volatiles, and air in the mold, after the plastic reaction in the plastic mold cavity proceeds to a proper time, It can release pressure and exhaust for a short time. Exhaust operation can shorten the curing time and improve the physical and mechanical properties of the product, and avoid stratification and bubbles inside the product; but too early, sooner or later will not work, too early to achieve the purpose of exhaust; too late, because the surface of the material is already The curing gas cannot be discharged.

(4) Curing: The curing of thermosetting plastics is to keep them at the molding temperature for a period of time, so that the polycondensation reaction of the resin reaches the required degree of crosslinking, and the product has the required physical and mechanical properties. Plastics with a low curing rate can also be cured temporarily when the product can be completely demolded, and then post-processing is used to complete the entire curing process; in order to improve the utilization rate of the equipment. The molding curing time is usually the holding pressure and holding time, generally ranging from 30 seconds to several minutes, and most of them do not exceed 30 minutes. Too long or too short curing time will affect the performance of the product.

(5) Demoulding: Demoulding is usually done by ejector rods. Products with molding rods or some inserts should be removed first with special tools, and then demolded.

(6) Mold blowing: After demolding, the mold cavity and mold surface are usually blown with compressed air. If the fixation on the mold is tight, it can also be cleaned with a copper knife or a copper brush, or even a polishing agent brush, etc. .

(7) Post-treatment: In order to further improve the quality of products, thermosetting plastic products are often post-treated at a higher temperature after demolding. Post-treatment can make the plastic curing more complete; at the same time, reduce or eliminate the internal stress of the product, reduce the moisture and volatile matter in the product, etc., which is beneficial to improve the electrical performance and strength of the product.

MB/Wechat/Whatsapp:+0086-13456489912

sophiemould@foxmail.com

Post time: Jul-11-2021