Carbon fiber is a high-performance structural material with many performance advantages, such as light weight, high strength, high temperature resistance and corrosion resistance. Therefore, carbon fiber has been used in aerospace, medical equipment, rail transit, automobile industry and other fields with its outstanding performance advantages. Carbon fiber compression molding is a commonly used carbon fiber product molding process. During the molding process of the carbon fiber compression mold, the required carbon fiber products can be made by adjusting the pressure, temperature and time. The products produced by the compression molding method have high carbon fiber content, and the surface of the products is smooth and flat with high strength.

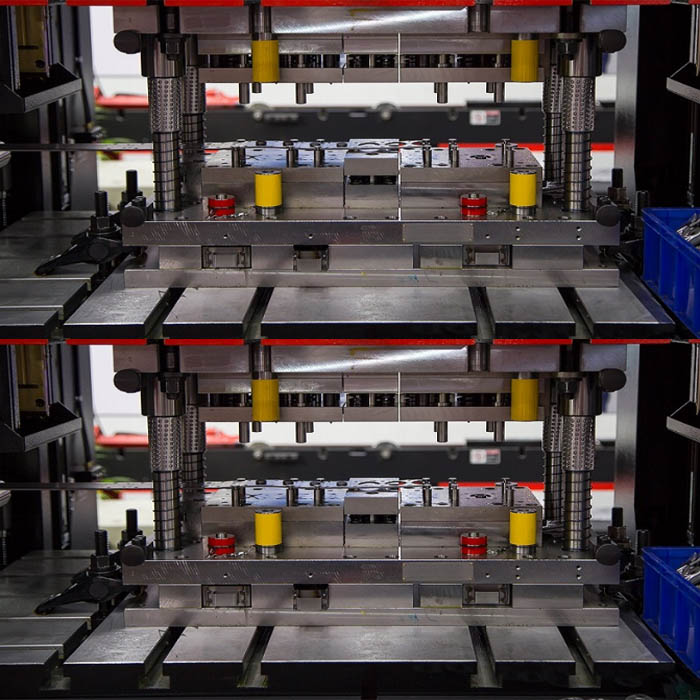

The main process of carbon fiber compression molding: Before starting, clean the mold to keep the mold smooth, and then preheat the mold to a certain degree to ensure that the carbon fiber prepreg can fit the mold. Then a certain amount of release agent is applied to the cavity of the carbon fiber compression mold to prevent the carbon fiber product from adhering to the mold. Lay the cut carbon fiber prepreg on the mold. Under the pressure of hydraulic equipment, the temperature will continue to rise after closing the mold and keep it warm.

The pressure in compression molding is mainly used to overcome the vapor pressure generated by volatile substances in the material, thereby avoiding defects such as product delamination, bubbles and loose product structure. At the same time, the pressure can also enhance the fluidity of the material and promote the carbon fiber to better fill the mold. In the carbon fiber compression molding process, the time for applying pressure also has certain requirements. If the pressing time is too early, the cross-linking reaction of the material will decrease and the fluidity will increase. However, when the pressure is applied too late, the degree of crosslinking reaction of the carbon fiber material is high, the fluidity becomes poor, and it is difficult to fill the mold, and the quality of the obtained carbon fiber product will also be reduced. For some thick products, appropriately increasing the pressure is conducive to forming.

In compression molding, temperature has a greater impact on the melting, flow and solidification process of the material. Temperature control during molding mainly refers to molding temperature, heating rate, molding curing temperature and holding time. An excessively high molding temperature will promote the cross-linking reaction of the material, which will cause the resin in the prepreg to be inconsistently cured inside and outside, and the resulting carbon fiber product is prone to cracking and deformation. In the production process, it is necessary to control the temperature of the mold, combine with the temperature of the resin curing point, and adjust different temperatures in different time periods. In order to prevent undesirable phenomena such as warpage, the mold must also be cooled. If the temperature is too low, the fluidity of the material will become poor, and the crosslinking reaction will not proceed sufficiently, which will result in a decrease in the strength of the carbon fiber product.

DEYING has carbon fiber processing technologies such as carbon fiber compression molding and autoclave molding. We provide a full set of solutions for carbon fiber compression molds, carbon fiber auto parts, and so on.

Application of compression molding

Compression molding has countless applications. The following are many parts and products with compression molding that we interact with:

Vehicle parts-Many large parts and panels of cars, tractors and other vehicles are made using compression molding. Many plastic parts used in vehicle interiors and engine parts can also be compression molded.

Kitchenware-Many kitchen tools, utensils and parts of household appliances are molded. Tableware including bowls, cups, plates, etc.

Electrical components-Compression molding is often used to make power sockets, switches, panels and metering devices.

Medical and dental equipment parts-Many plastic and silicone parts used in the medical industry are compression molded, including syringe plugs and gas masks.

MB/Wechat/Whatsapp:+0086-13456489912

sophiemould@foxmail.com

Post time: Aug-06-2021