Many companies in the aerospace, automotive, construction, and electronics industries are using composite materials to reinforce plastic parts or replace metal stamping parts. The composite material can be glass, thermoplastic, phenolic or epoxy. When thermosetting resins melt, they form permanent heat-resistant materials that cannot be modified without degradation. When thermoplastic resins melt, the materials they form will soften or melt when heated, and harden again when cooled. Thermoplastics have strong and lasting adhesion at room temperature, and can be softened by heating without losing strength or degradation.

The main process for forming thermoset and thermoplastic parts is thermoforming. What is hot press forming?

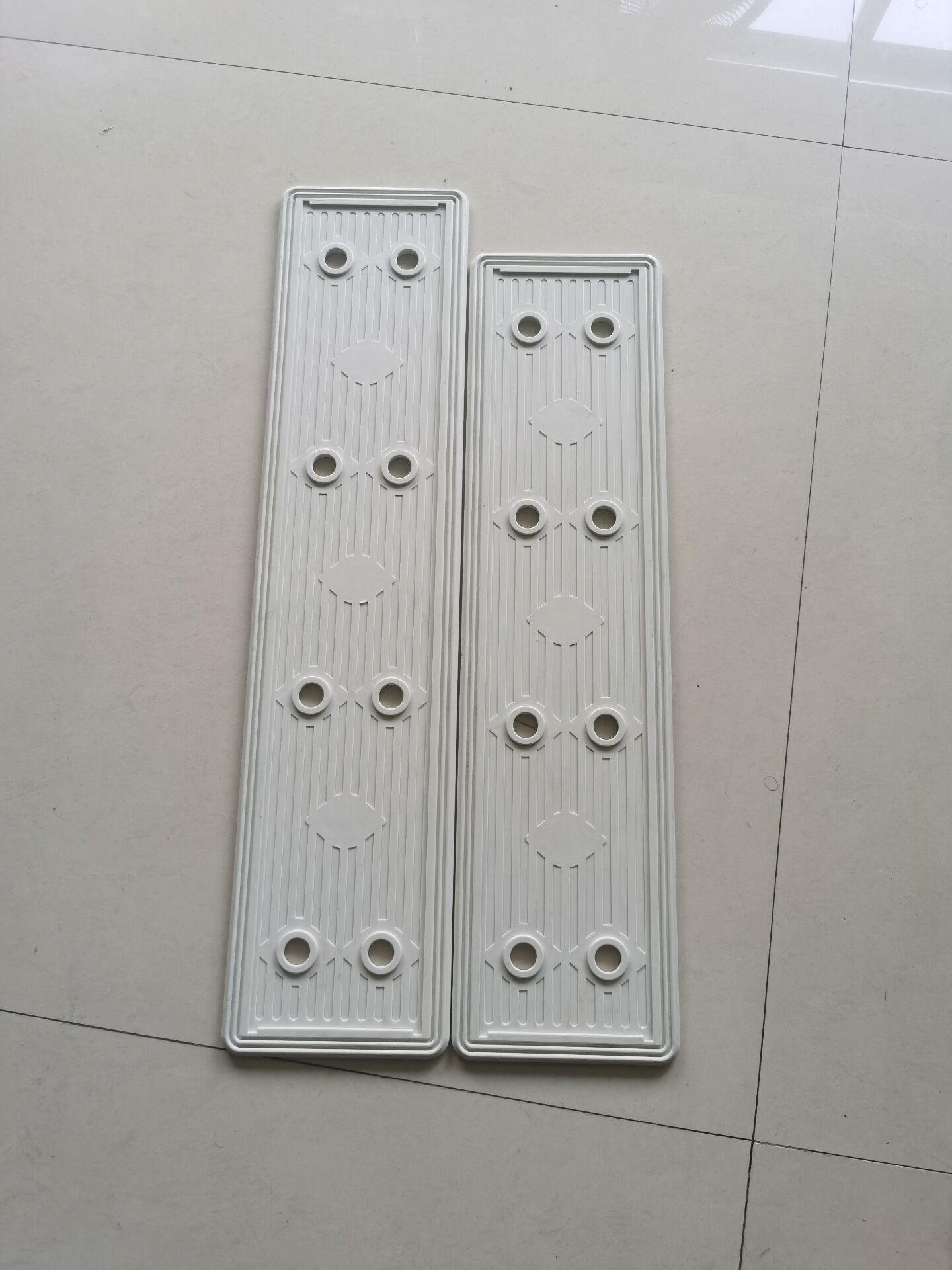

Compression molding is a method that uses pressure and heat to form large parts. Generally, the hot press forming mold needs to withstand a constant pressure and maintain it for a period of time to form a part. First, the material is preheated and placed in the heated mold cavity. Close the mold, apply pressure to fill the cavity with the material, and maintain the heat and pressure until the molded material solidifies. Commonly used heating for thermoforming molds includes electric heating, steam/hot water heating and oil heating. Since hot press molding uses heat and pressure to change material properties, it is suitable for molding complex, high-strength compounds for custom applications. Generally, these parts are lighter than metals and have an equal or greater strength-to-weight ratio.

Advantages of hot pressing compression mould:

Single-step forming process

Short curing time

Reduce investment (compared to injection molding process)

Highly automated.

DEYING has been engaged in the hot press forming mold industry for more than 20 years. We design and manufacture hot press forming molds for customers, and continue to accumulate experience in hot press forming technology.

MB/Wechat/Whatsapp:+0086-13456489912

sophiemould@foxmail.com

Post time: Sep-03-2021