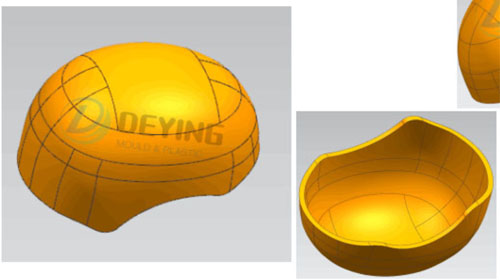

The quality of FRP helmets is very good. fiberglass helmets have high strength, good flexibility and strong impact resistance. It is a better helmet in the market today, and has advantages in all aspects than plastic helmets.

Professional glass fiber reinforced plastic helmet mold production plant,welcome contact .

Commonly used FRP mold positioning mechanism types

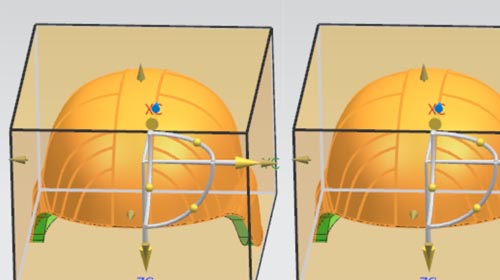

Organizations with lateral parting and core-pulling are collectively referred to as row-position mechanisms. There are many types of travel agencies and various classification methods. According to the usage characteristics of various types of position structures, the commonly used position structures can be summarized into the following categories:

(1) Front mold positioning mechanism of FRP mold

(2) Rear mold positioning mechanism

(3) Insider institution

(4) Hafuma mechanism

(5) Inclined top and swing rod mechanism

(6) Hydraulic (pneumatic) positioning mechanism

Design requirements for glass fiber reinforced plastic mold position

Each component of the positioning mechanism should have reasonable processing technology, especially the forming part. General requirements:

A. Try to avoid line clamping. If it is unavoidable, the clamping position should be located in a position where the plastic part is not obvious, and the clamping length should be as short as possible. At the same time, a combined structure should be used as much as possible so that the line clamping position and the cavity can be processed together.

B. In order to facilitate processing, the forming part and the sliding part should be combined as much as possible. The components of the travel mechanism and its assembly parts should ensure sufficient strength and rigidity.

The positioning mechanism is generally designed based on experience, and it can also be simplified. In order to ensure sufficient strength and rigidity, the general situation is:

A. Large structure size. In the case that the space position can be satisfied, the row component adopts a large structure size.

B. Optimum design structure of glass fiber reinforced plastic mold. For example, the following situations 1) Position the end of the longer needle to avoid bending the needle

MB/Wechat/Whatsapp:+0086-13456489912

sophiemould@foxmail.com

Post time: May-08-2021