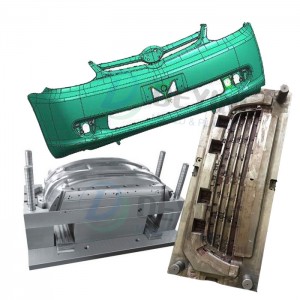

Plastic injection food containers are widely used in our daily life, various containers around us. From 100ml-20L. From 0.5mm to 1.5mm. From food to industrial use. Like ice-cream container, snacks container, oil package container ect.

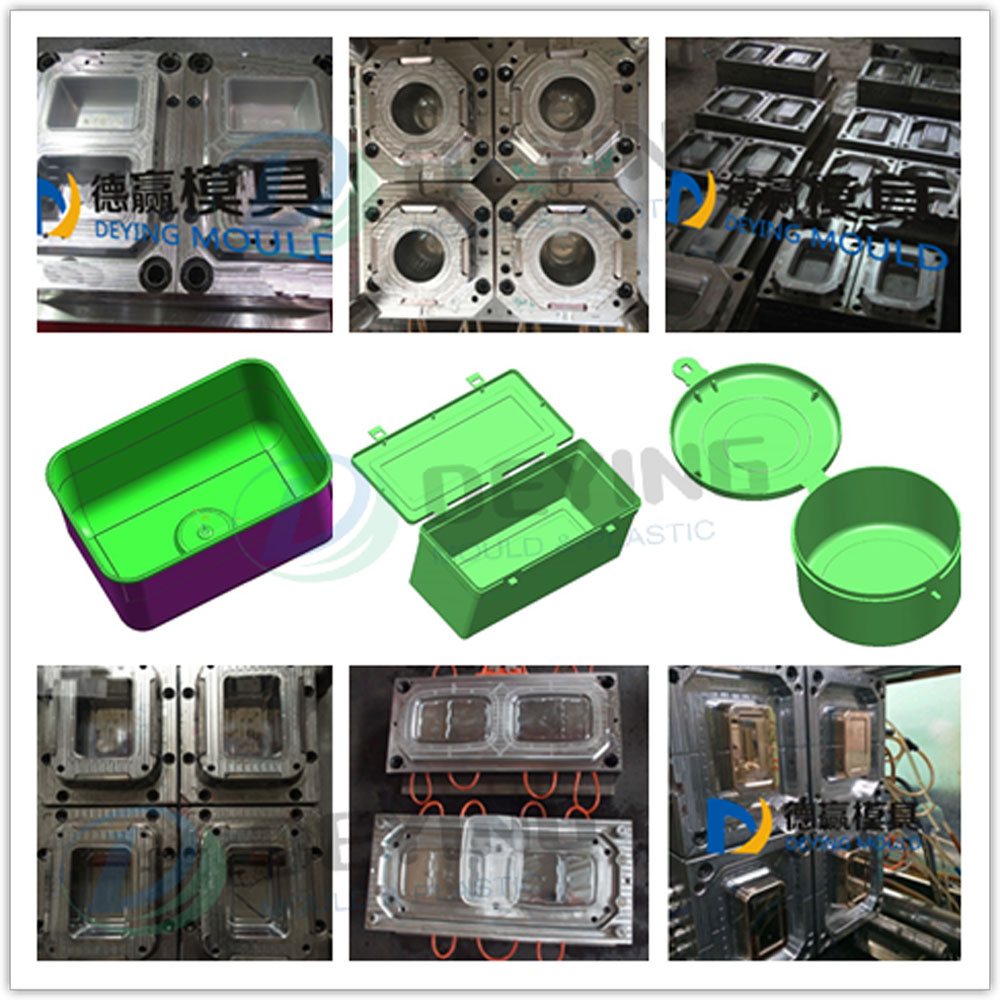

Mould Name:plastic food container mold thin wall container mould

Product Size:Various size

Mould Cavity: 1+1 cavities ,2+2 cavity ,4+4 cavities

Mould Main Material: S136 or H13

Mould Injection System: valve gate system + 8 tips hot runner

Mould Ejection System: air vent

Mould Cycle Time: 13-18 Seconds

Mould Running: 3M

Delivery Time: 50 working days

Mould Features: stacking mould with high speed molding

For food container molding, DEYING design multi-cavity container BOX in separate cavity molding inserts locking system, this can saving the tooling period time, also can avoid the tooling mistake risk for high precision mould process.

It have to use high speed milling machine, fast flow of the raw material inside cavity by valve gate system, effective cooling system for the mould temperature control and high speed moving of each step. We also offer IML molding system for food container molds.

From 100ml upto 1500ml box mould, round box mould, thinwall IML molding box get high production capacity for profit.

DEYING MOLD supplies a complete set of multi-cavity transparent container molds with different sizes. The capacity includes 100ml, 200ml. 250ml. 500ml, 1000ml, large like 18 l, 25 l, 60 l, 110 l and so on.

There are two types of transparent containers:

1. Single-use food packaging, usually single-use products are ultra-thin containers with a wall thickness of 0.4-0.6 mm. Xinuo mold can produce 4 cavity 1 l ultra-thin container mold with a wall thickness of 0.4 mm. It can run 10s/shots with 400 tons injection molding machine.

2. Not disposable. Another type of plastic container has a wall thickness of about 0.8-1 mm. At present, we have a set of container molds that can produce seven different sizes and shapes, which can be used with some container lids. The entire design can be stacked on each other, which greatly occupies the area of the container and also greatly reduces the logistics cost.

3. All transparent container molds need to be polished well. In order to make the container look shiny, we usually use DIN1.2738, DIN1.2344, S136 as the mold cavity steel. If the container wall thickness is thick, 718 h steel can be used to reduce mold costs. We provide molds according to our customers' requirements.

Deying Mold specializes in providing technical support for total molding line solutions. For more information, please feel free to contact us.