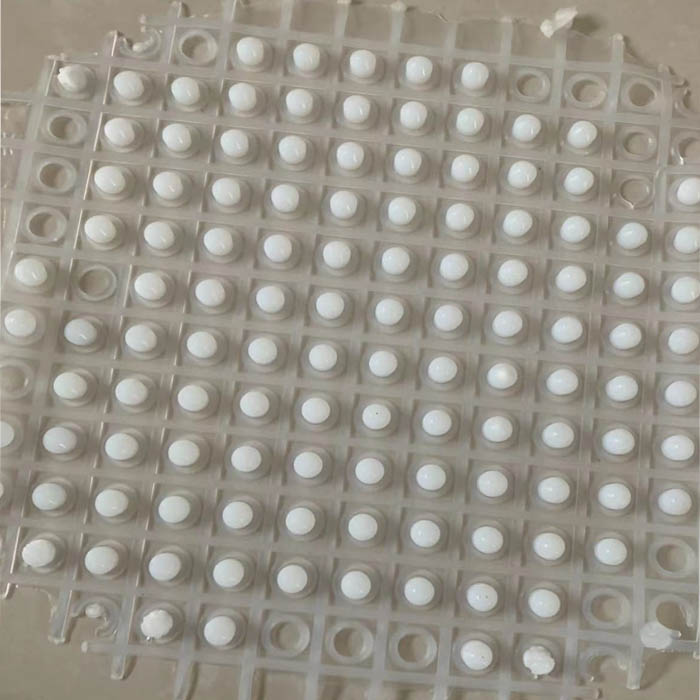

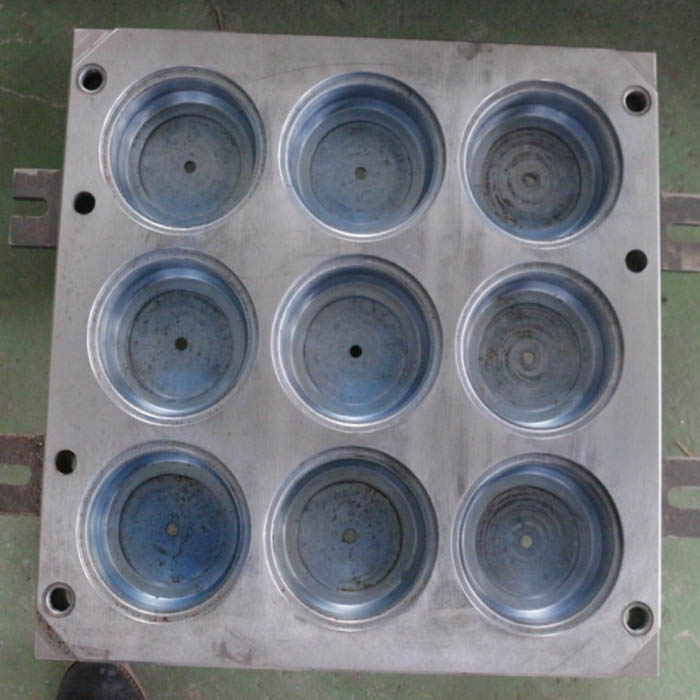

DEYING MOULD has rich experience in producing rubber molds. Can provide you with a variety of O-shaped, gaskets, miscellaneous parts, shock-absorbing parts, dust covers, self-adhesive foot pads, grip rubber parts, hardware rubber parts and other silicone and rubber product molds. At the same time, we can also make various special-shaped molds for you to meet your needs.Vulcanized Seal Rubber Products mould customized production, fast delivery

The product made from rubber as raw material and vulcanized under high temperature and high pressure with a mold is called a rubber model product. The larger one has automobile tires, and the smallest one has a lighter sealing ring with a diameter of only 50 millimeters. The mold material, dimensional accuracy, exhaust and mold opening difficulty, etc. all directly affect the quality, labor intensity, and production efficiency of rubber products. At the same time, the selection of mold material, heat treatment and other manufacturing processes, as well as the quality of mold assembly, directly affect the service life of the mold. Therefore, when designing the mold, firstly, we should carefully analyze and study the characteristics of the shape and structure of the rubber parts, and use this as a basis to select and design a reasonable mold structure, reasonable material and heat treatment process to meet the requirements of rubber products and the use of molds. It is required that the mold is easy to open after vulcanization, which can provide the production efficiency and the service life of the mold, thereby improving the economic benefit.

MB/Wechat/Whatsapp:+0086-13456489912

sophiemould@foxmail.com

-

Customized FRP SMC Steel Mold for Manhole Cover...

-

taizhou SMC BMC DMC FRP square energy gas meter...

-

salad box molds plastic bento lunch box mould

-

Hospital laboratory medical Disposable urine sa...

-

SMC BMC manhole cover mould FRP compression com...

-

wall Mounting household commodity junction box ...