Under normal circumstances, it is a problem with the data of the main working parts of the manhole cover mouldings. Any mold problem has a certain reason. Improper selection of materials, poor performance of the data, non-wearing, unrefined mold steel, and a large number of smelting defects, craftsmanship It is not perfect, and there are hidden dangers of heat treatment. Or it is the problem of mold structure design. Excessive unloading force will increase the alternating load of the punch. The molding process is imperfect, the heat treatment technology and craftsmanship are problematic, the soft point and hardness are uneven, microcracks or even cracks occur, the grinding and polishing are not in place, and the surface roughness.

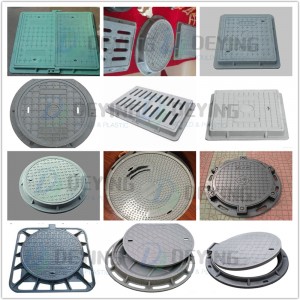

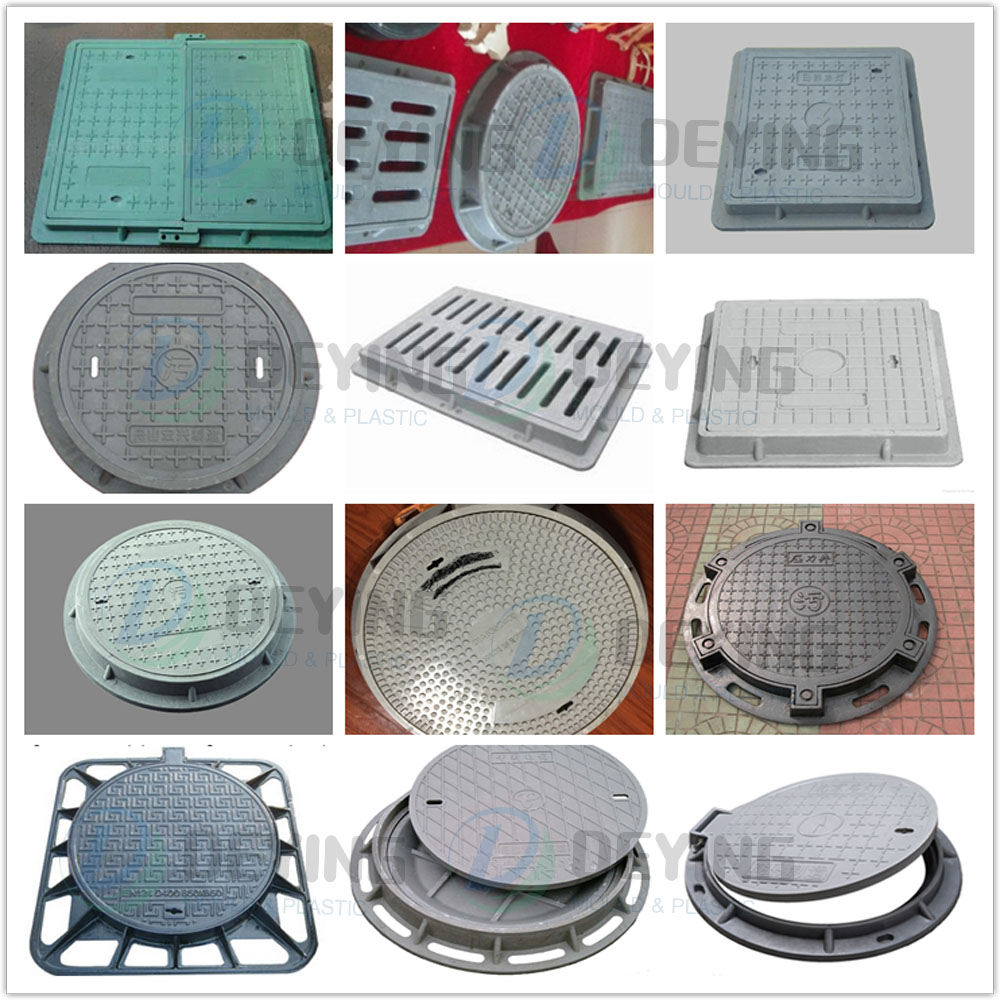

Molds are driven by high-tech and pillar industries to form an industrial chain, involving equipment, building materials, municipalities and other industries. The trend of the domestic manhole cover mold market continues to rise, and the proportion will continue to increase.

After a period of application, the manhole cover mold should be sharpened, and then demagnetized, otherwise it is prone to blockage. In the application, the punch is easy to be broken. When replacing, the punch and the punch sleeve must be exchanged with the same specifications. In the usual maintenance, check whether the accessories of each part are in good condition. If there are abnormal places, they should be replaced in time to avoid affecting the later use.

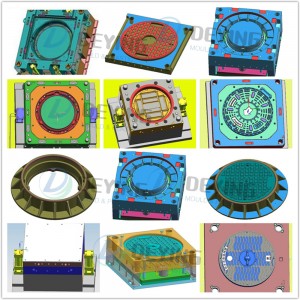

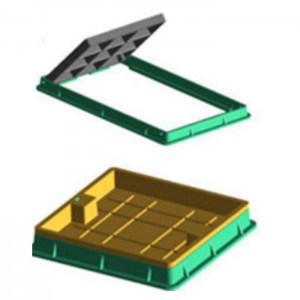

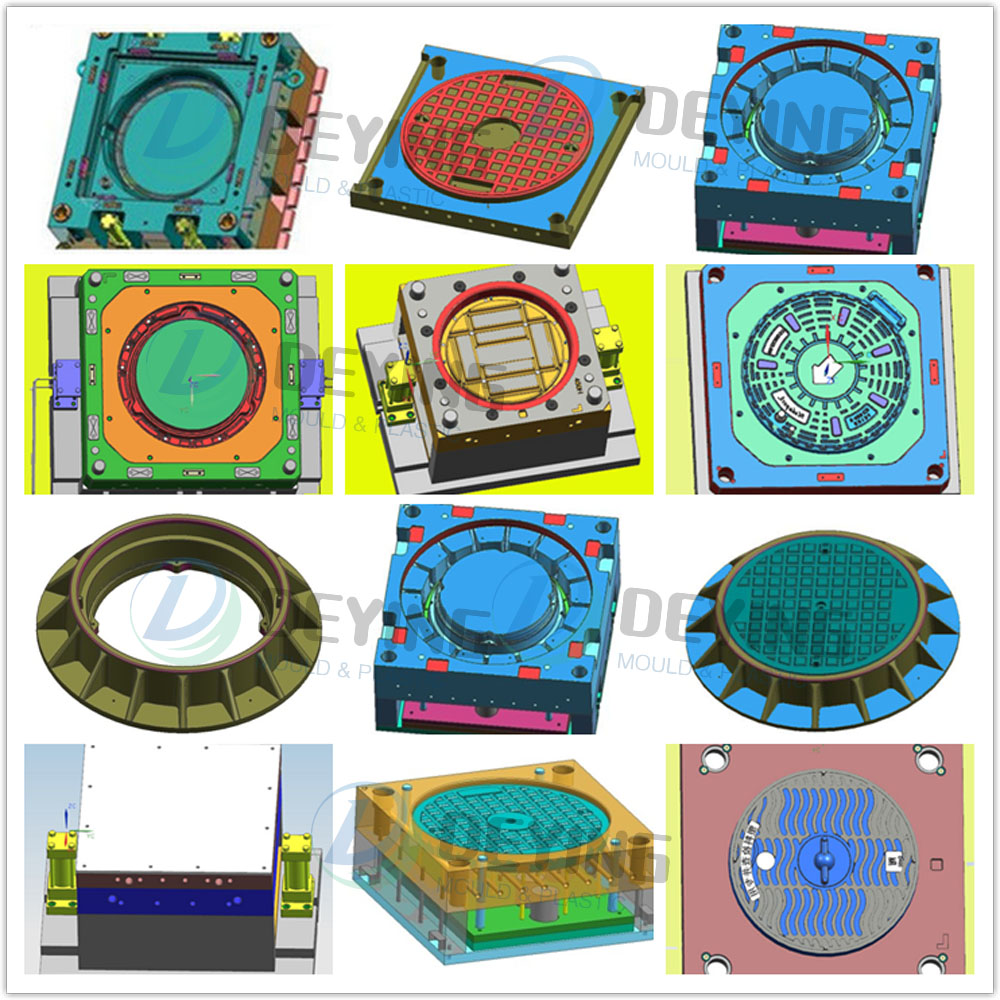

The composite molds we produce have been effectively optimized, have a longer service life, lower manufacturing costs, and their products can achieve higher precision.

DEYING MOLD adheres to the tenet of "survive by quality, development by science and technology, benefit by management, and market by reputation", and constantly strengthen technological innovation, improve management, improve quality, provide customers with the best quality products, and strive to be first-class Our company and brand! Our factory provides first-class services for municipal construction and beautification of the urban environment! Sincerely welcome friends from all walks of life to call or write to negotiate business!

MB/Wechat/Whatsapp:+0086-13456489912

sophiemould@foxmail.com