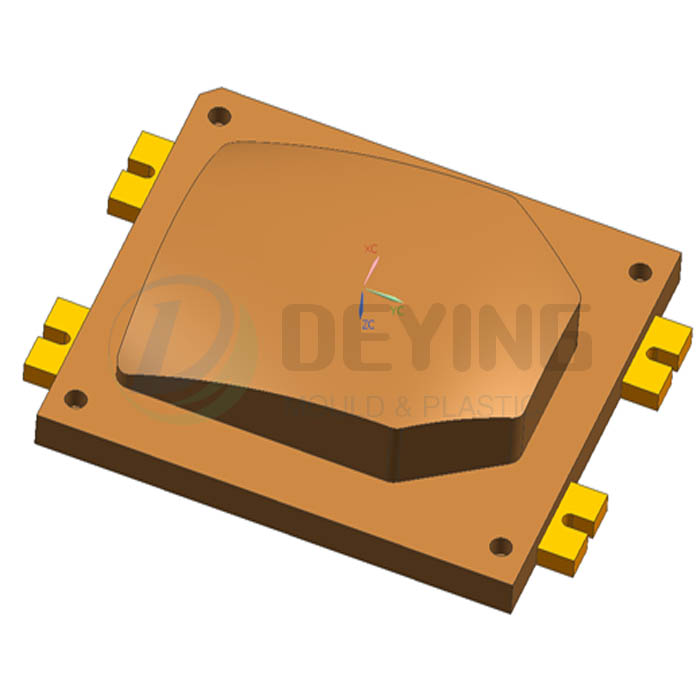

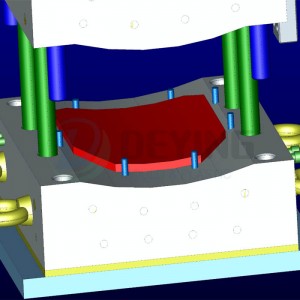

We have very mature technology to produce ballistic Ceramic Insert Plate mould,achieve pressing of different thickness plates through spacers.revolutionary technology—DEYING MOLD brings Mutual benefit.Please select a specification you need and send me a mail. DEYING will contact you as soon as possible.

Compression molding is a method of molding in which the molding material, generally preheated, is first placed in an open, heated mold cavity. The mold is closed with a top force or plug member, pressure is applied to force the material into contact with all mold areas, while heat and pressure are maintained until the molding material has cured.

MB/Wechat/Whatsapp:+0086-13456489912

sophiemould@foxmail.com

-

Army Multi-Curve UHMWPE Ballistic plate mould

-

China Supplier Customized Mold Pressed UHMWPE p...

-

High Quality PE Material Bulletproof Plate mold...

-

Body Armor Plate molding DIY Homemade curved Ba...

-

Bulletproof Army Plate mould Military armor Pla...

-

Armor Plate mouldings Ballistic Helmet molds fa...