Deying Mold Making Process Flow

1. Sawing machine cutting

2. Milling machine processing

3. External vacuum heat treatment

4. Grinding machine processing

5. CNC machining (programming)

6. W/C (wire cutting)

7. EDM (spark machine)

8. Polishing

9. The fitter assembles OK, tryout

Checkpoints after mold assembly is completed

1. Check the list to see if all the parts have been loaded.

2. Check each part and mark it clearly marked according to the drawing.

3. Check if every part that needs to be moved on the injection molding machine is lubricated or not.

Check the position and orientation of each component against the drawing or 3D image. After the mold parting surface is blown with an air gun, it is confirmed that the mold is smoothly closed before the mold can be tested.

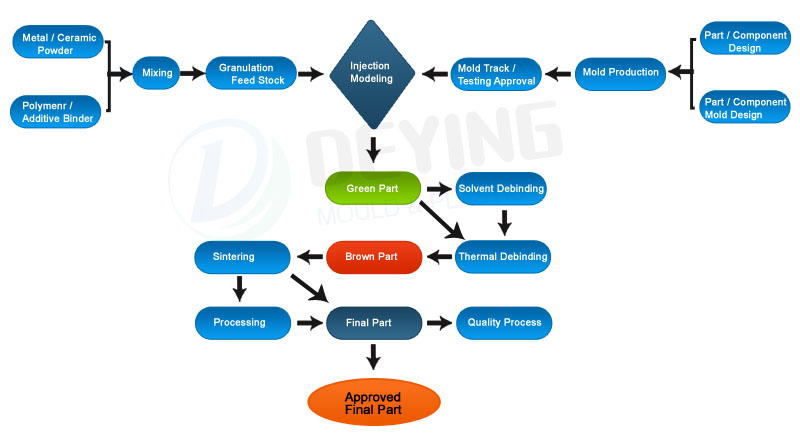

Injection Moulding Metal Injection Molding Process Flow Diagram Flowchart

Post time: Aug-15-2019