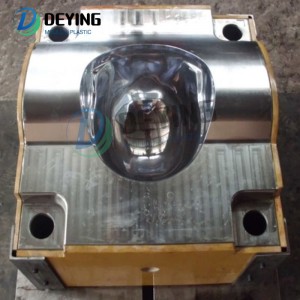

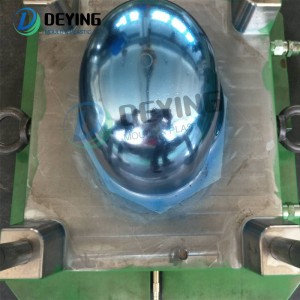

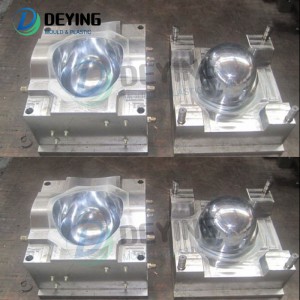

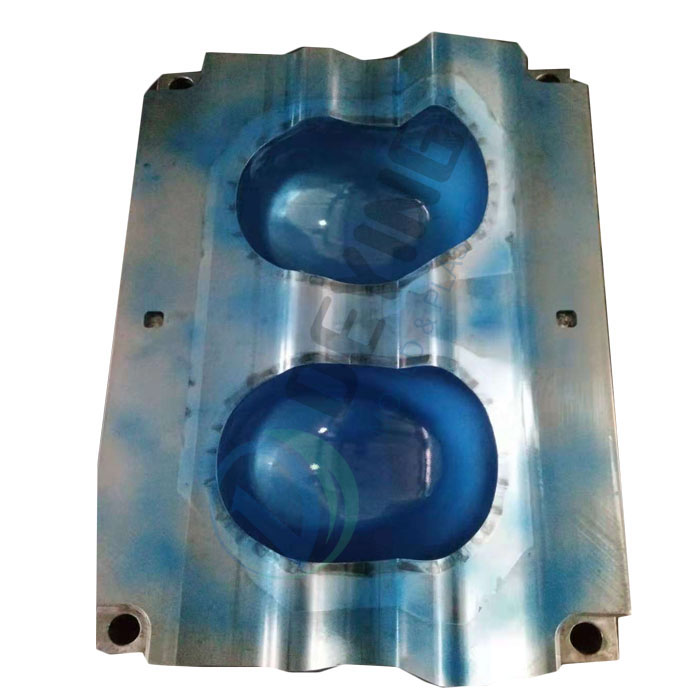

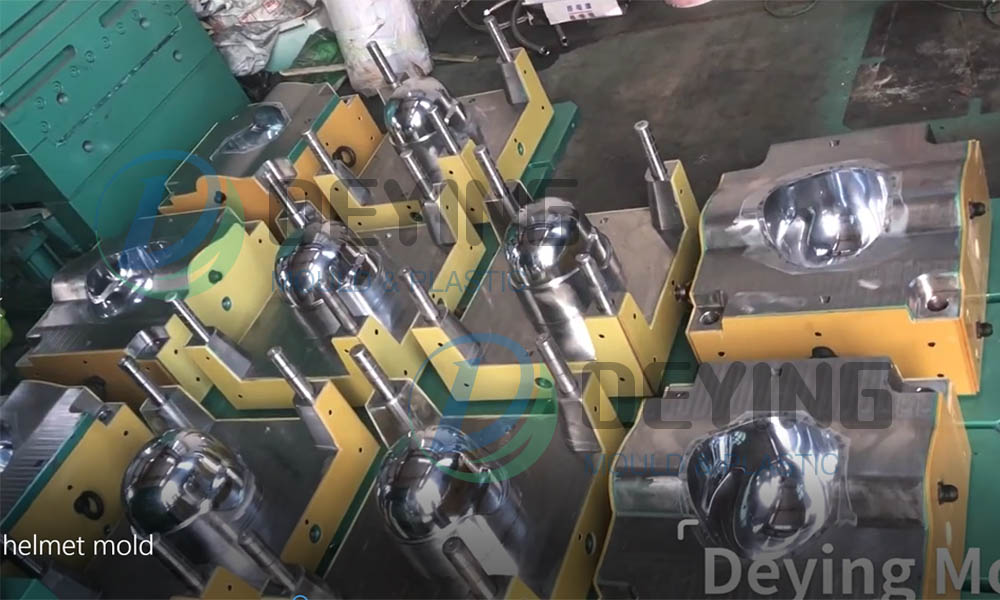

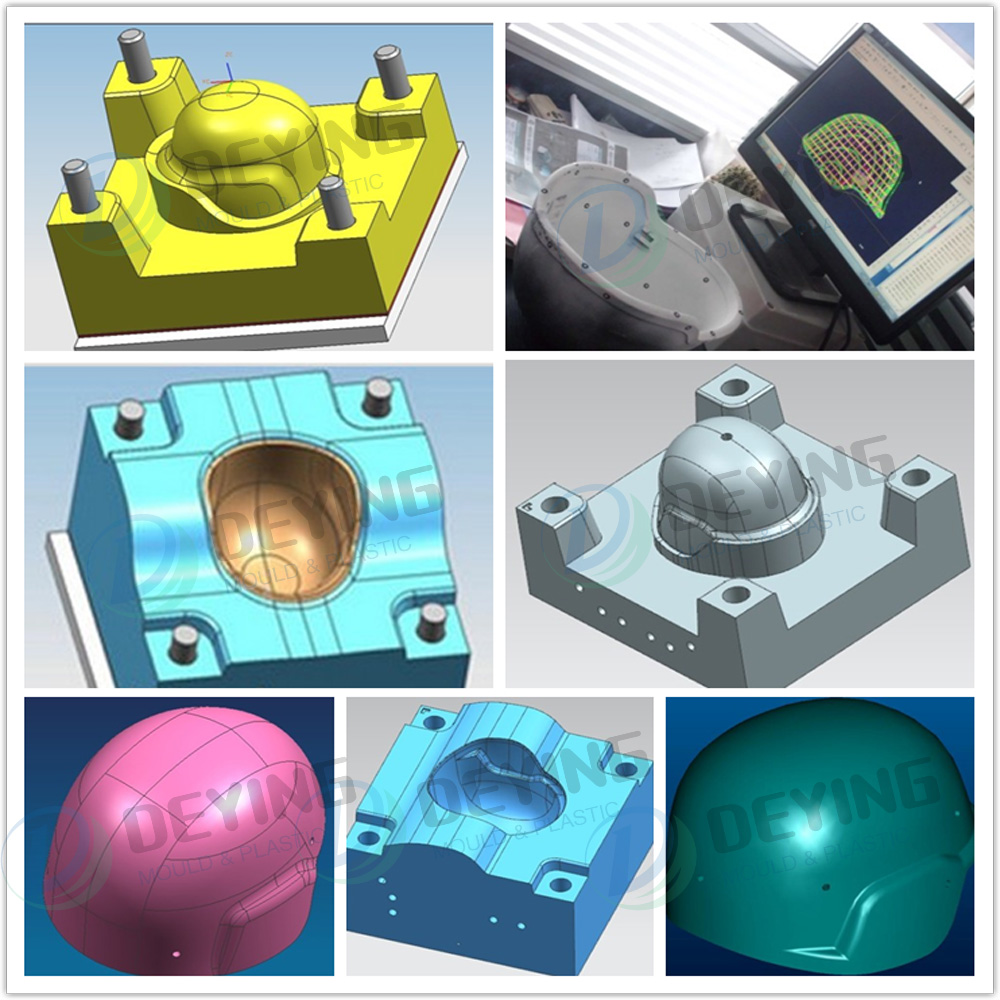

China's mold supplier specializes in producing various types of military helmet molding and various of specifications aramid Bulletproof Helmet moulds,we also supplying Armor helmet mold Solutions.

PE/KEVLAR ballistic bulletproof helmet, bulletproof armour, bulletproof shield, missile wing, transmitter support, tear gas shell etc.mold

With these new polyethylene composites being used in bulletproof helmet. What’s the downside? The cost of these polyethylene helmet is quite a bit more than the cost of kevlar.

The Compression Molding Process

Compression molding requires a mold, which will be machined from steel or aluminum and will be designed to satisfy dimensional and tonnage requirements.

As material properties are of great importance in the compression molding process and the establishment of process parameters, the process for thermosets and thermoplastics are similar but also differ in important ways.

Compression moldings

Parts manufactured in the compression molding process range from one ounce in weight to over 100 pounds and can mimic the strength and complex geometries of metal, doing so with anti-corrosive and electrically insulative properties. Products take many forms, from thin-walled containers to thick solid shapes including kitchenware, electrical housings, helmets, and airplane and automotive components.

Thermosets and thermoplastics come in a wide range of material options that differ in terms of price and performance. As such, compression molded Examples of resins and fibers used in the compression molding process:

Thermoset resins: SMC, BMC, TMC, epoxy, phenolic, melamine and urea.

Thermoplastic resins: polypropylene, nylon, UHMWPE, HDPE, and high temperature materials such as PEEK, PEKK and PAEK.

Fiber types: fiber glass, aramid, standard modulus carbon fiber, as well as other grades of carbon fiber.

MB/Wechat/Whatsapp:+0086-13456489912

sophiemould@foxmail.com