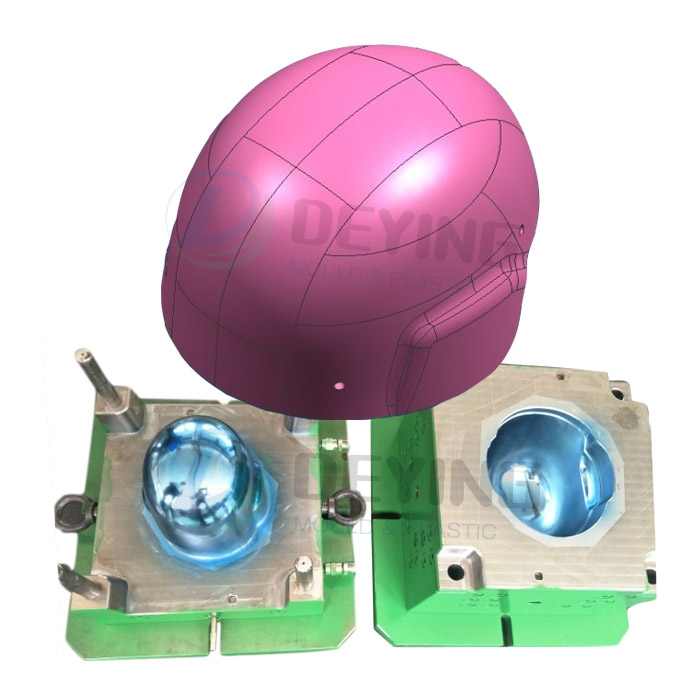

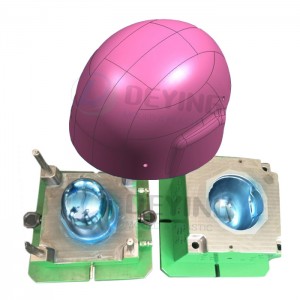

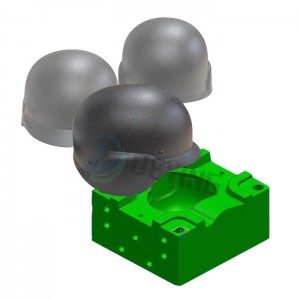

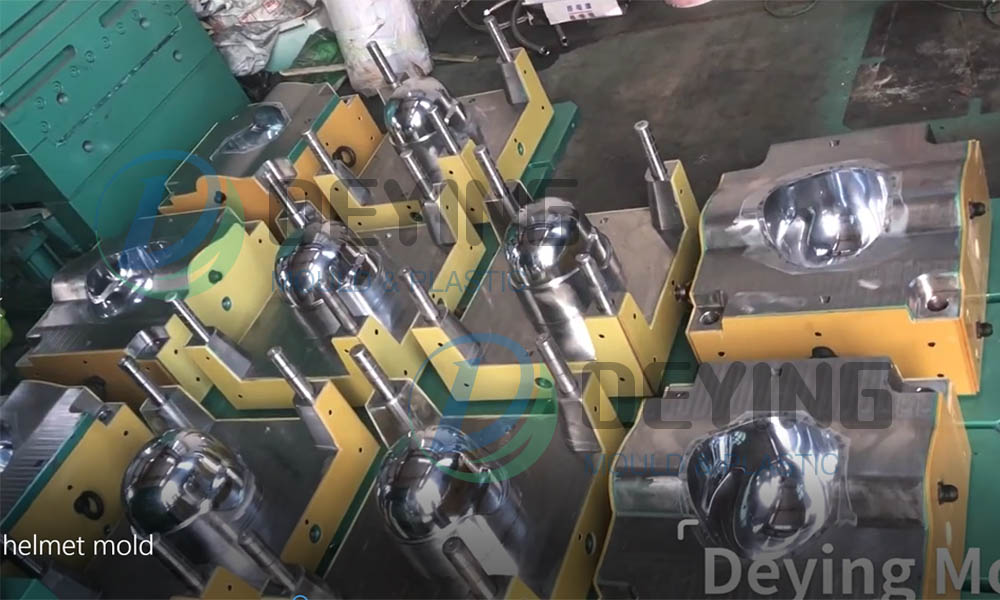

Deying Mould a professional production Tactical Bulletproof Helmet Moulds factory,has extensive experience in military field's product molds.Whether it is PE or Kevlar materials products, we can provide the perfect solution.

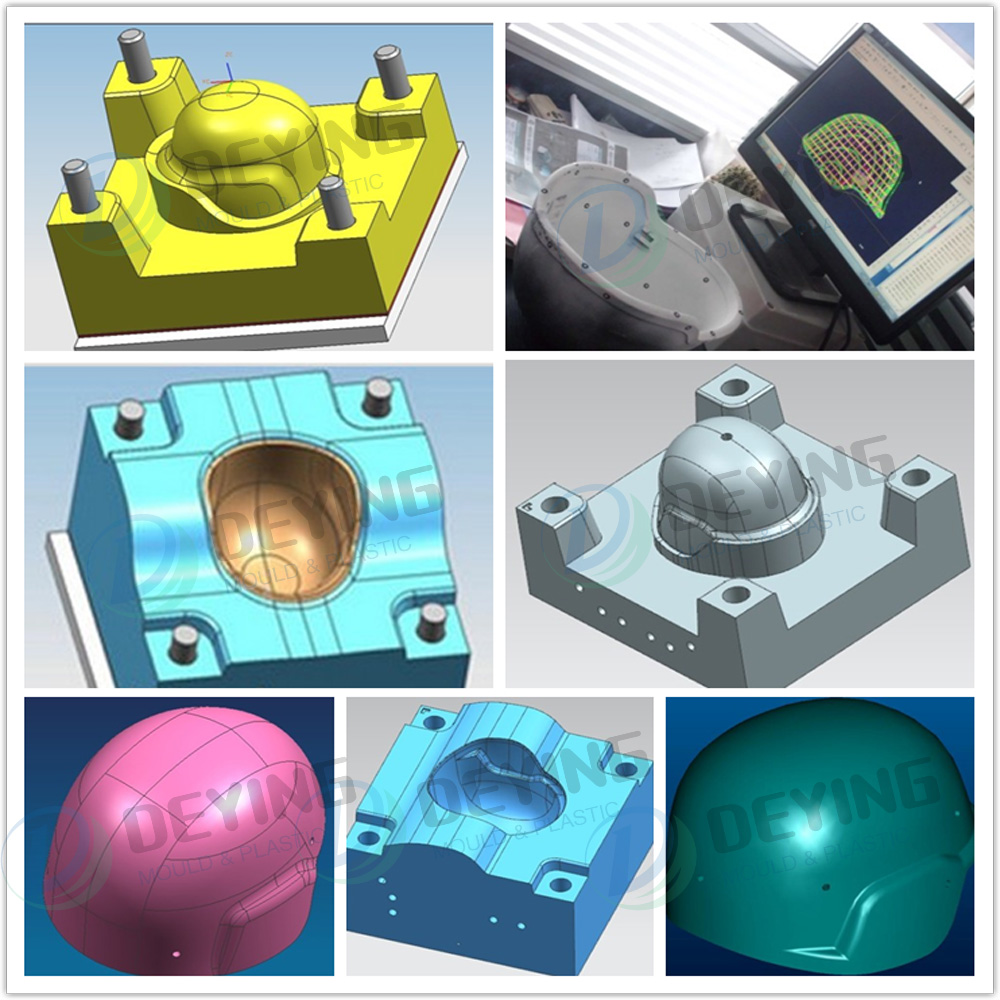

Deying is one of the largest manufacturers of ballistic helmet molds in China. Deying's unique mold forming technology enables customers to manufacture bulletproof helmets with low blunt trauma, typically 50% lower than other products. The helmet mold made by Deying Mould provides excellent comfort for the wearer of the bulletproof helmet series.

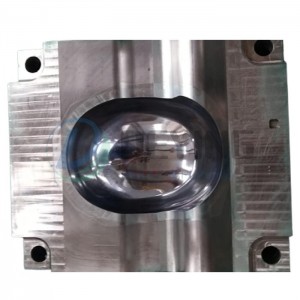

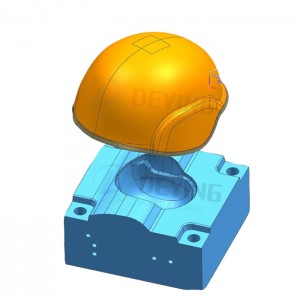

To make high-precision composite products, composite molds are the most important part of the entire manufacturing process. And the shape and appearance of the product need to be guaranteed by the mold. The composite material mold usually puts the composite material into a hot pressing mold, and then melts the composite material by heating the mold. The mold is equipped with an ejection mechanism to eject the molded product to separate it from the mold. Common heating methods for composite molds include oil heating, electric heating, and steam heating.

MB/Wechat/Whatsapp:+0086-13456489912

sophiemould@foxmail.com