Kevlar Bulletproof Helmet Compression Mould Suppliers and Manufacturer in taizhou,chinese Full Cut Carbon fiber Bulletproof ballistic Helmet mold making

Carbon fiber Helmet mold tips?

1.Material

A helmet which commonly referred to as "carbon fiber" was produced by impregnating a fiber as a support structure with a "binder" hardener resin and determining the strength and characteristics of the helmet.

The common glass fiber is the most economical and less resistant supporting component and weight is big & strength ratio is quite disadvantageous.

Carbon fiber is a long and thin wire consisting mainly of carbon atoms, and thousands of carbon fibers are entangled to form a fabric with very high tensile strength. To give an idea, for more durable and higher quality fibers, the tensile modulus or resistance that can withstand without breaking is greater than 140 M.psi.

The production is carried out by hot molding after precise delamination of the fabric and impregnation of the resin or by autoclaving.

2.How to produce ?

1.Cutting of the various sectors in carbon fabric and carefully check the sense of fibers.

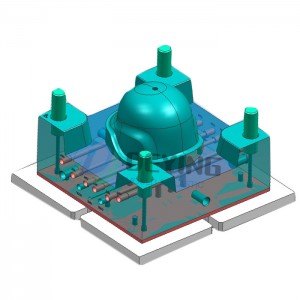

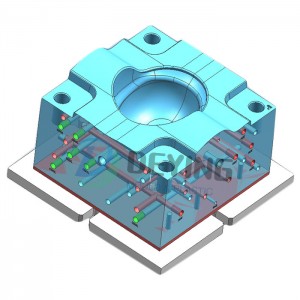

2.The operator inserts the various sectors into heated mold based on a pattern pre-established to tests which have determined the best resistance yield.This operation have to carried out by high precision and attention ,because it determines quality of helmet will be obtained.

3.Operator injects with a automatic system into heated mold to an exact temperature a precise dose of pre-mixed liquid epoxy resin, inserts the counter-mold which adheres precisely the resin measured on the whole surface of mold or of cap.

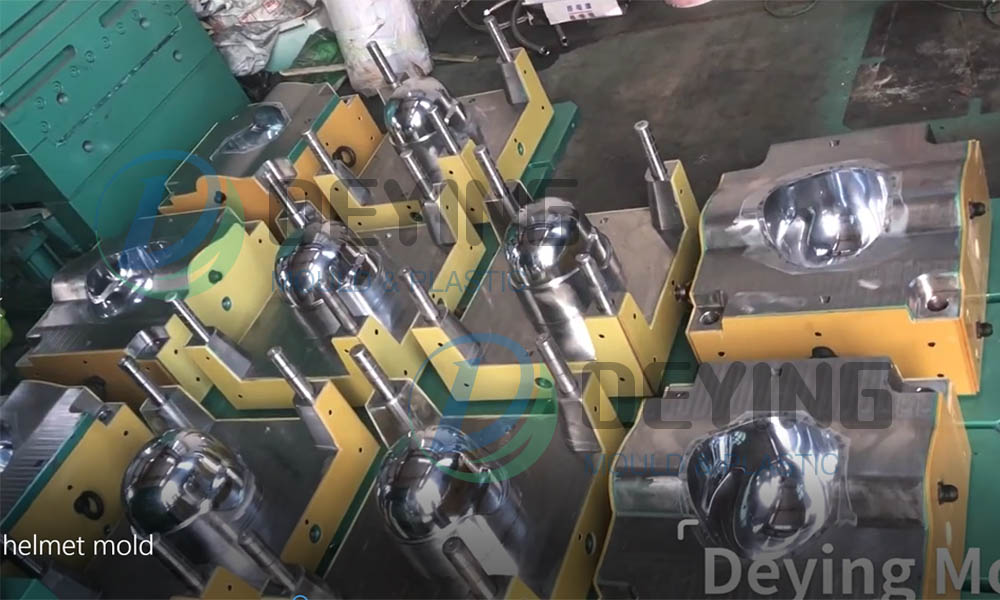

4.The molding cycle time to obtain a quality product is about 40 minutes .

5.The quality of helmet obtained often depends on the skill and experience of the person who produces it and controls it.

6.We're go on proceed to the milling of window and the holes of rough shell with a diamond-coated CNC cutter or with a water cut.

7.The last phase is that of grinding to eliminate the burrs, and then paint with a special low coefficient of thermal expansion paints in order to not have cracking over time due to the high stability of the shell.

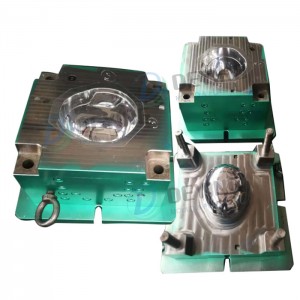

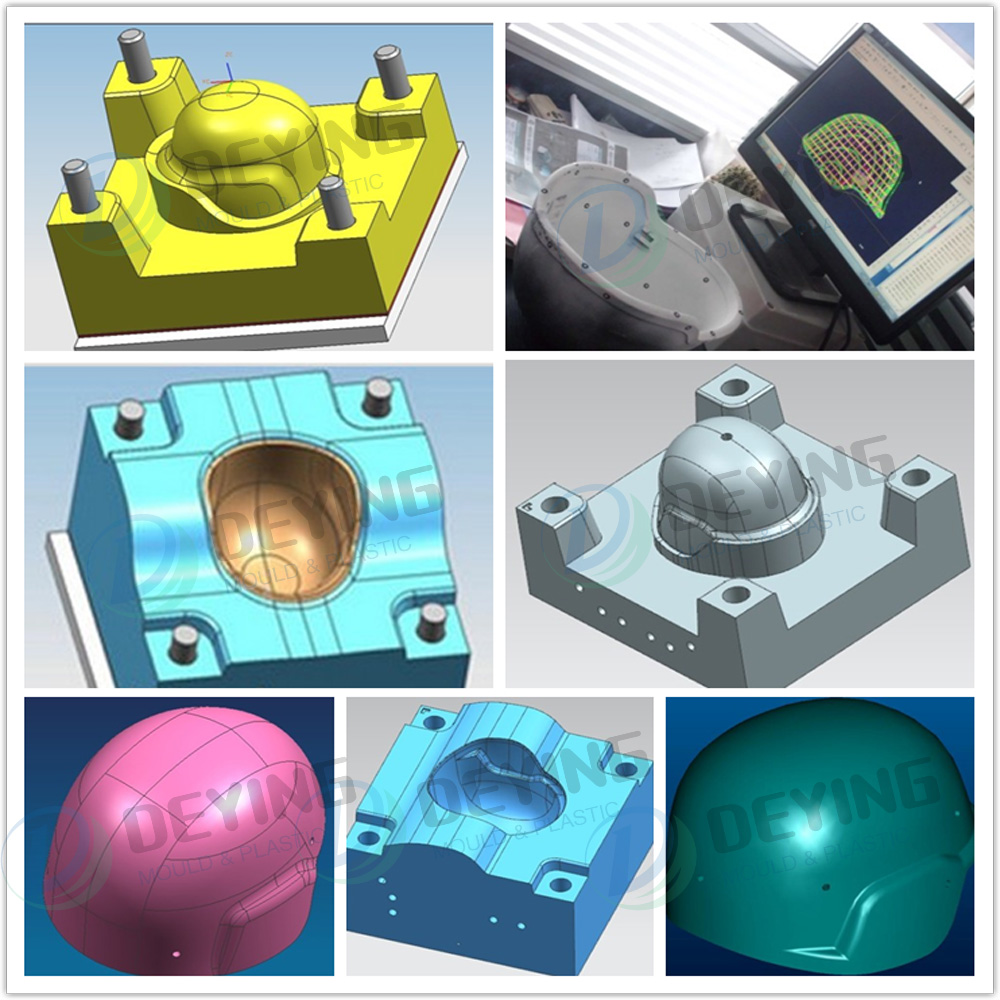

Production of Kevlar bulletproof helmet molds, EPS helmet molds, safety helmet helmet molds---DEYING Mould specializes in the production of Kevlar/PE bulletproof series mold

Mold name: Kevlar PE bulletproof helmet mold

Mold raw materials: H13,8418,8407,38CrMoAl,5CrNiMo,S50C,40Cr,P20, etc.

Plastic parts raw materials: Kevlar, UHMWPE, etc.

Mold base: LKM, LYM standard, self-made mold base (can be customized according to customer requirements)

Mold hardness: 28-55HRC

Heating system: electric heating, oil temperature heating, steam heating

Manufacturing cycle: 30-60 working days

Mold life: 100,000 times -500,000 times

Mould accessories: Jinghong, HASCO, DME, PUNCH, etc.

Mold design software: UG, PROE, Catia, Solidworks, AutoCAD

Packing: standard wooden box (according to customer requirements)

After-sales service: If there is any problem in the process of using the mold, we will send an experienced engineer to help you solve it

MB/Wechat/Whatsapp:+0086-13456489912

sophiemould@foxmail.com