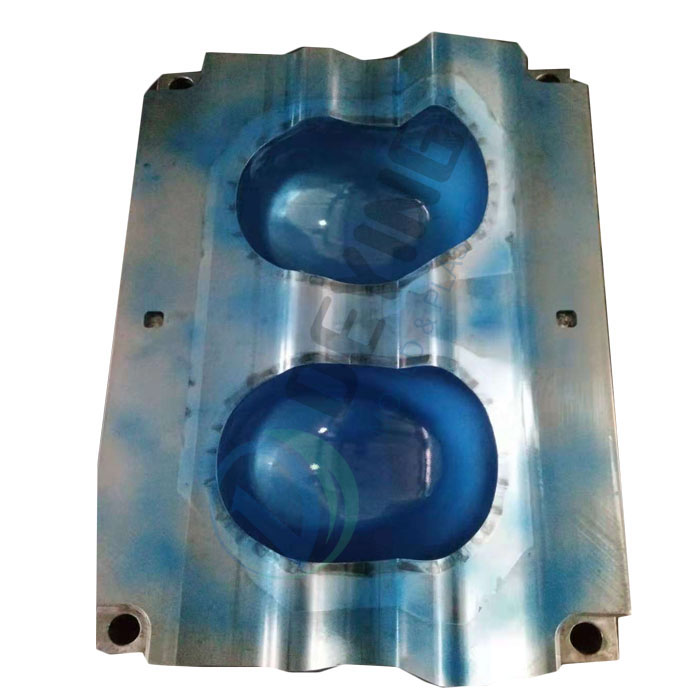

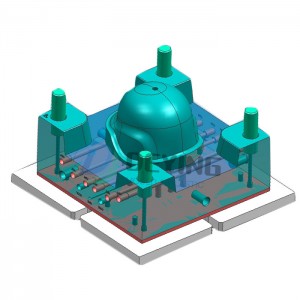

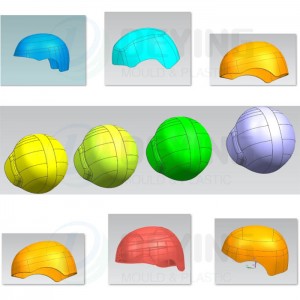

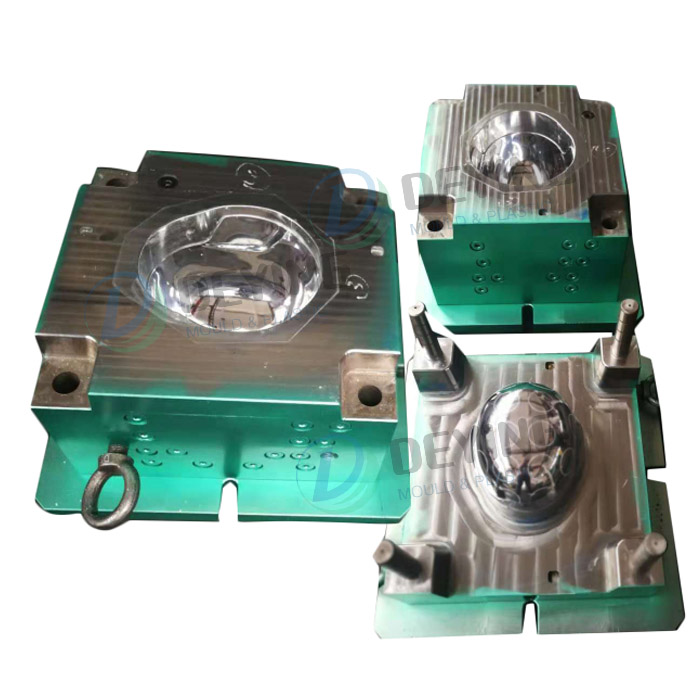

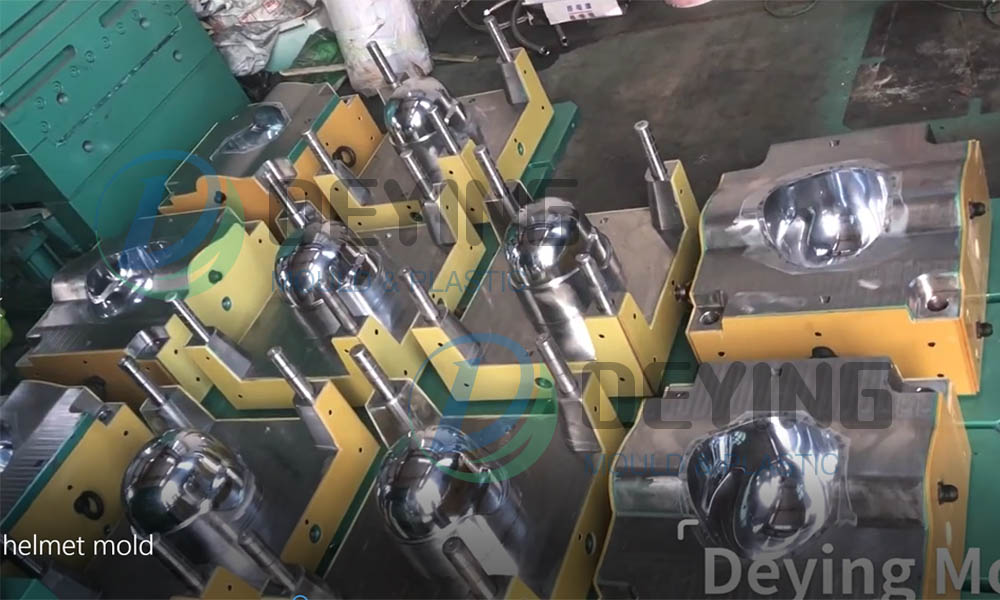

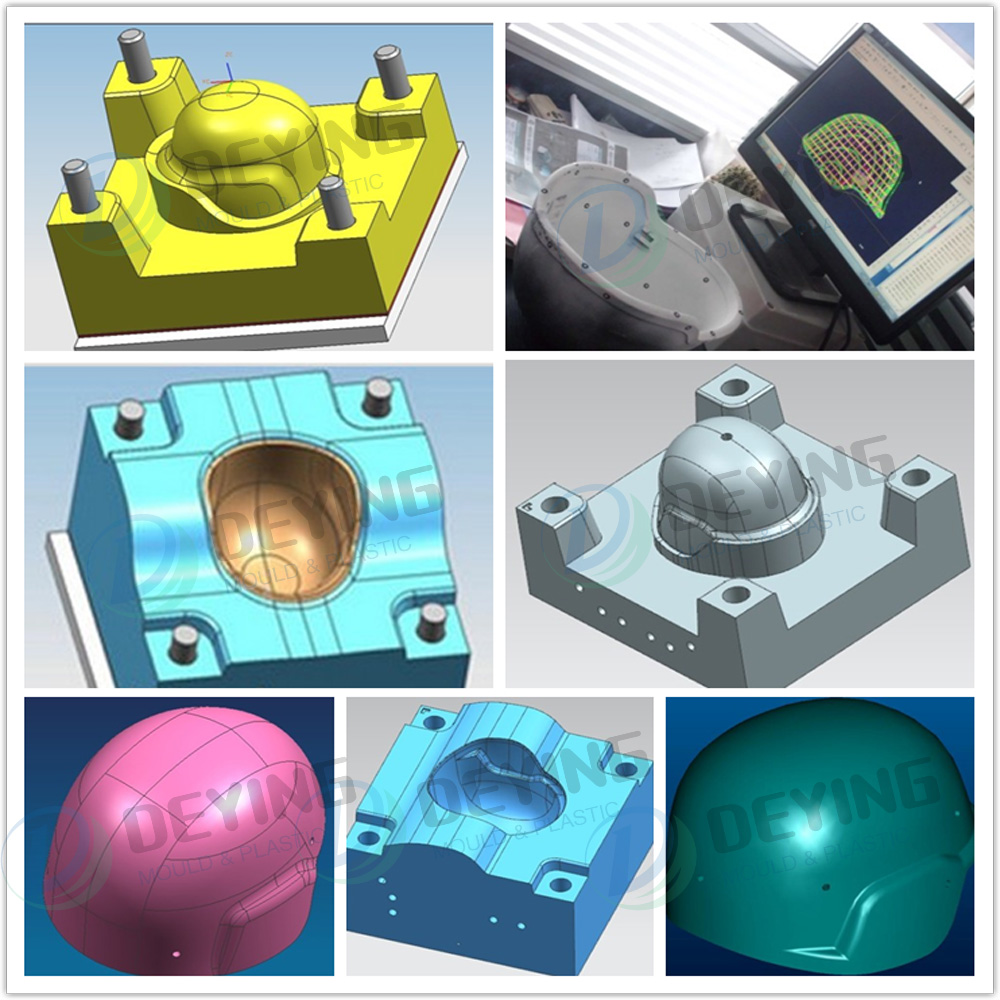

Deying Mold company own unique military product mold production technology, especially 2 cavities bulletproof helmet mold to help customers high efficiency production.

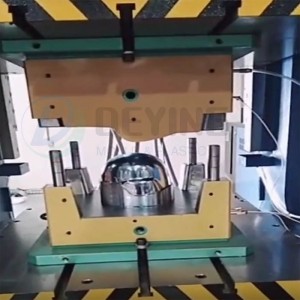

Polyethylene helmet compression moulds

ADVANTAGES OF COMPRESSION MOLDING

Compression molding is a popular technique for a number of reasons. Part of its popularity stems from its use of advanced composites. These materials tend to be stronger, stiffer, lighter, and more resistant to corrosion than metal parts, resulting in superior objects. Manufacturers accustomed to working with metal parts find that it is very simple to convert an object designed for metal into a compression molding part. Because it is possible to match metal part geometry with this technique, in many circumstances one can simply drop-in and replace the metal part altogether. Another advantage of compression molding is its ability to create very complex parts. While this technique can not quite reach the production speed of plastic injection molding, it does offer more intricacies in geometry than typical laminated composites. It also allows for longer fibers than plastic injection molding, resulting in stronger and stiffer materials. Therefore, compression molding can be seen as a middle ground between plastic injection molding and laminated compound fabrication.

With its ability to create complex parts with a huge variety of applications while keeping part cost and turnaround time a priority, compression molding is an advantageous process for manufacturers in a wide range of industries.

MB/Wechat/Whatsapp:+0086-13456489912

sophiemould@foxmail.com