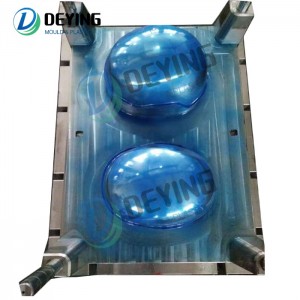

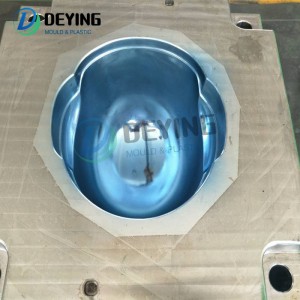

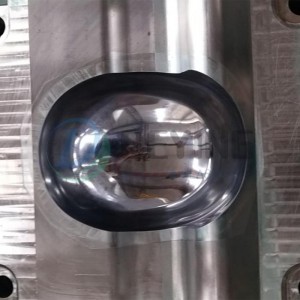

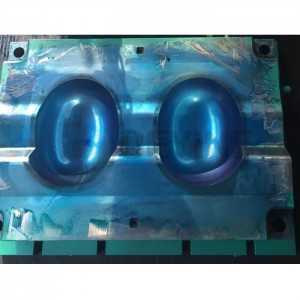

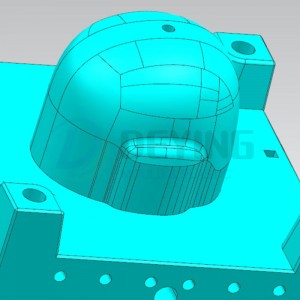

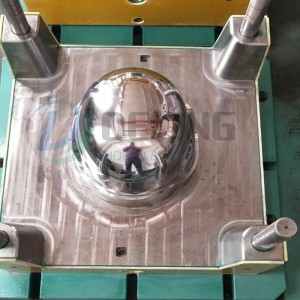

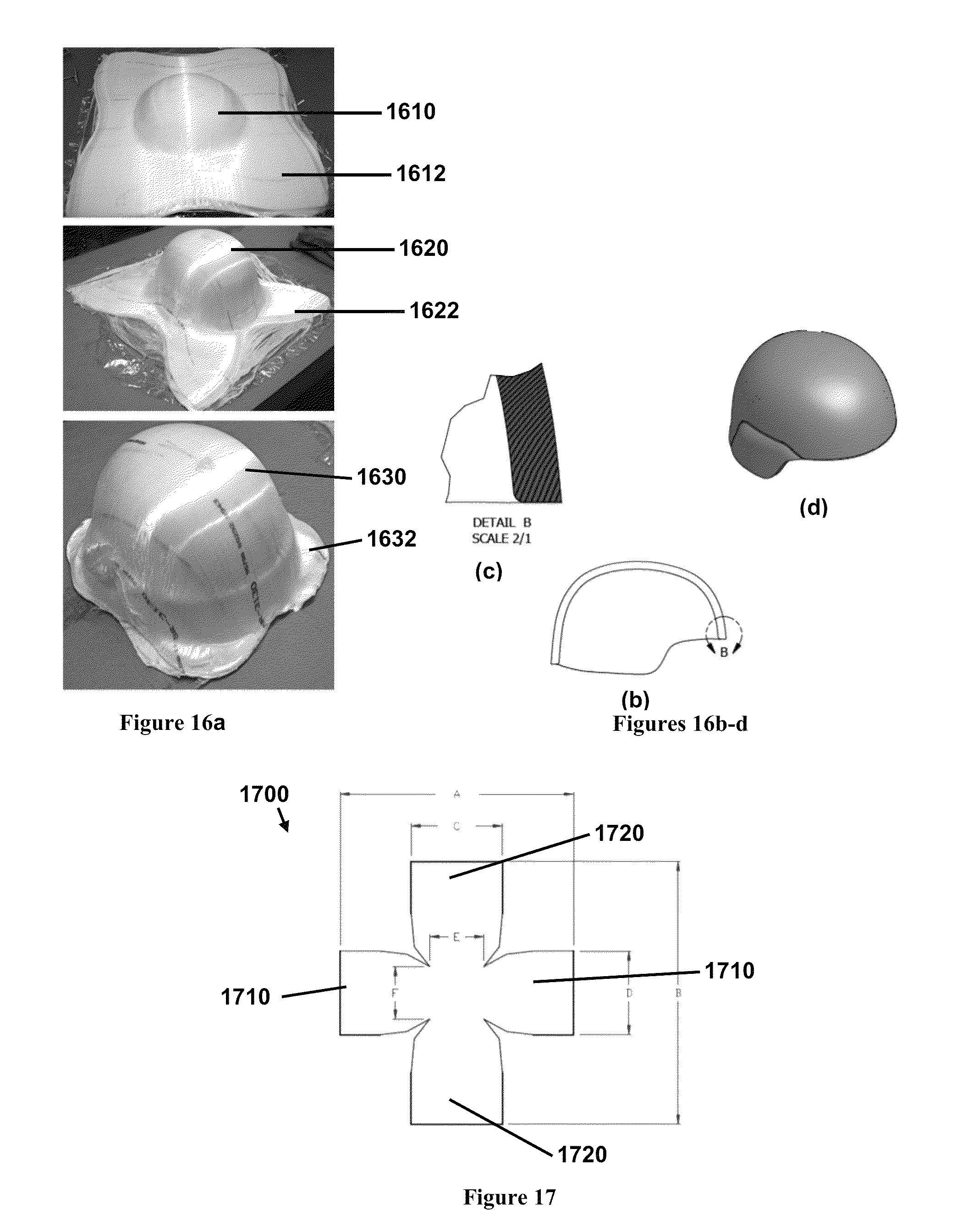

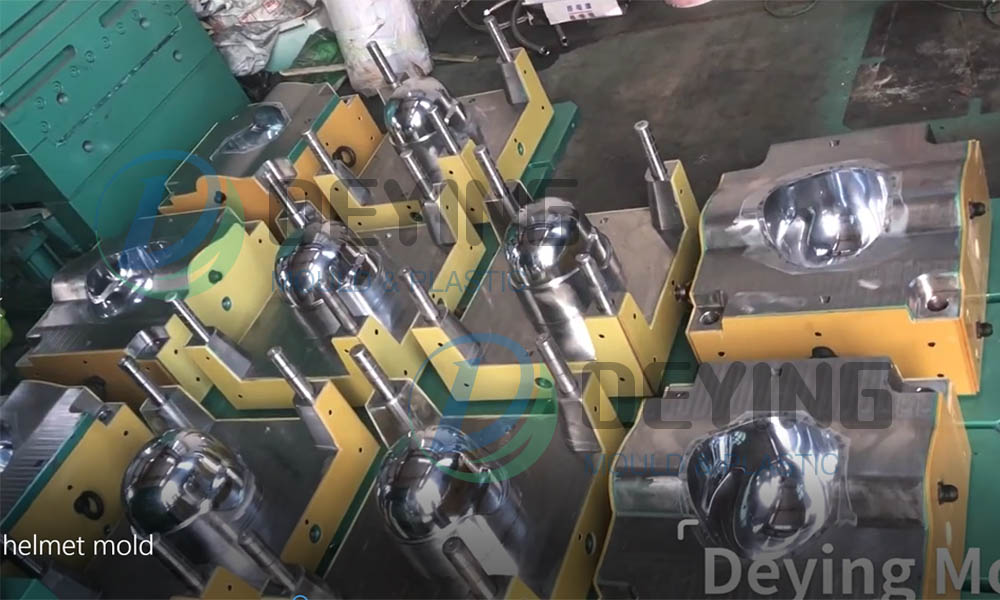

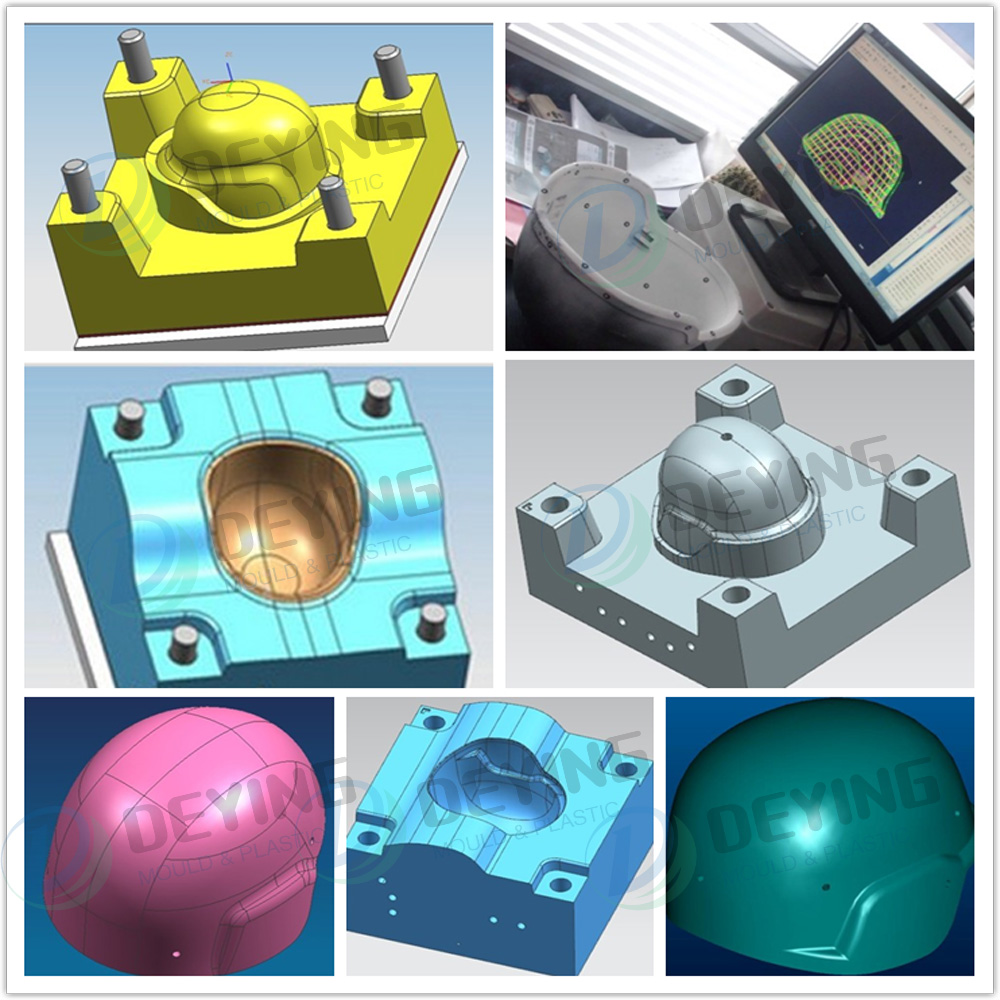

High Cut Ballistic Helmet mould is US Military shape and style .It is a lighter Helmet to ensure maximum comfort and flexibility.It also a version of the Advanced Combat Helmet mold

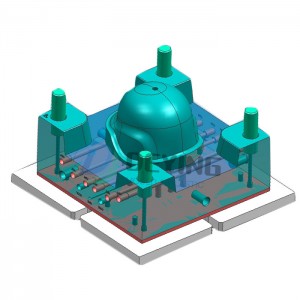

Quality gurantee ballistic helmet mold from china Reliable helmet mould suppliers

MICH Helmet (Modular Integrated Communications Helmet) also known as the Advanced Combat Helmet (ACH) is a ballistic combat helmet and is one of several used by military forces around the world. The MICH helmet is the primary combat helmet for use by Army and Law Enforcement.

MICH Ballistic Helmet can be provided with night vision support mount, Velcro pads and side rails for optional equipment.

Looking at just the weight factor, UHMWPE is by far the strongest fiber currently available on the market. They are 28% stronger, so vests made with these fibers are about 28% lighter. And, they’re substantially more flexible, which is another improvement.

MB/Wechat/Whatsapp:+0086-13456489912

sophiemould@foxmail.com