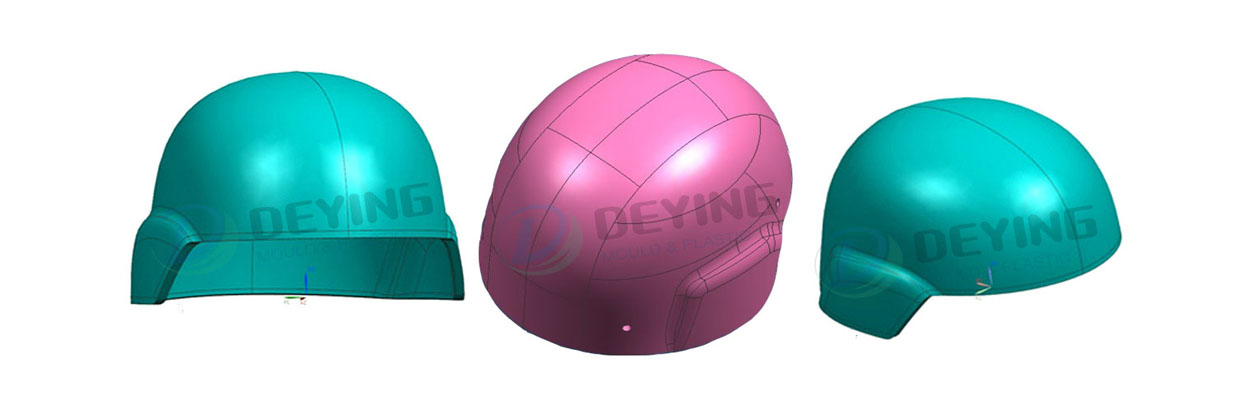

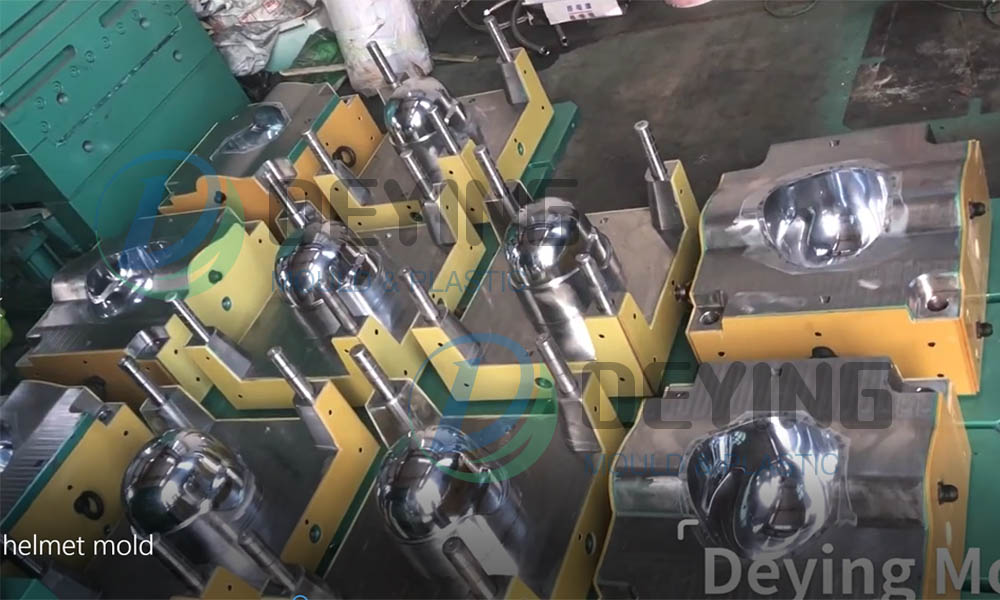

Deying is professional and earliest military products mold makers,smc anti-bullet Ballistic helmet mould selling for Global market

Our company has long cooperated with scientific research units and military industrial enterprises to explore the molding process and molds of composite materials, including carbon fiber molding dies and processes; UD/Kevlar bulletproof composite molding dies; PF phenolic resin and MF melamine resin molding dies and other compression molding Molds, applications include: automotive lightweight, bulletproof helmets and inserts, aircraft aerospace, insulated electrical and electrical fields and architectural decoration.

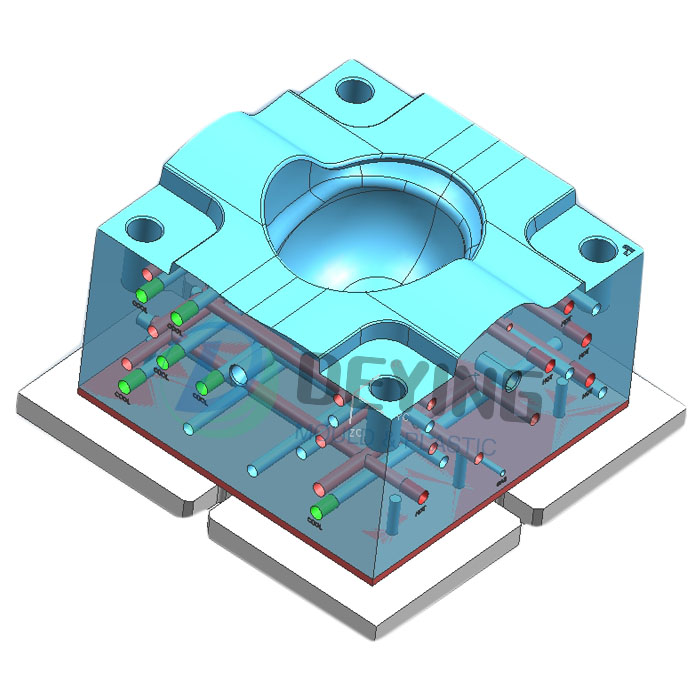

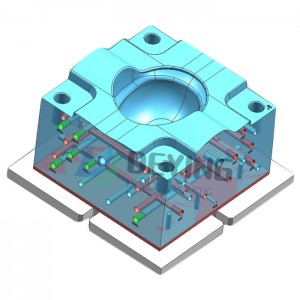

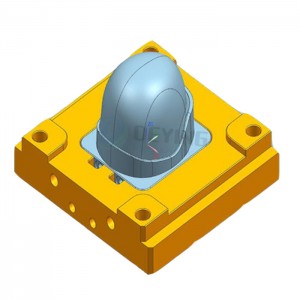

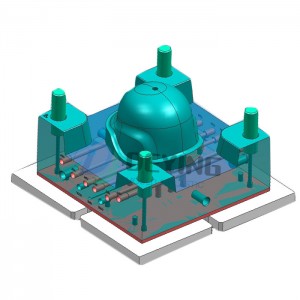

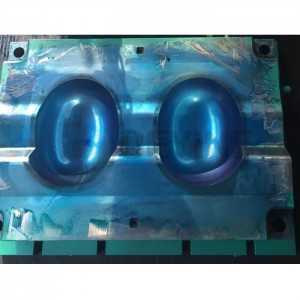

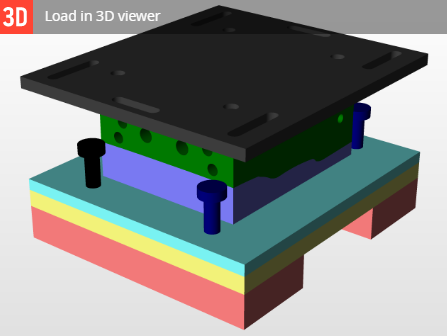

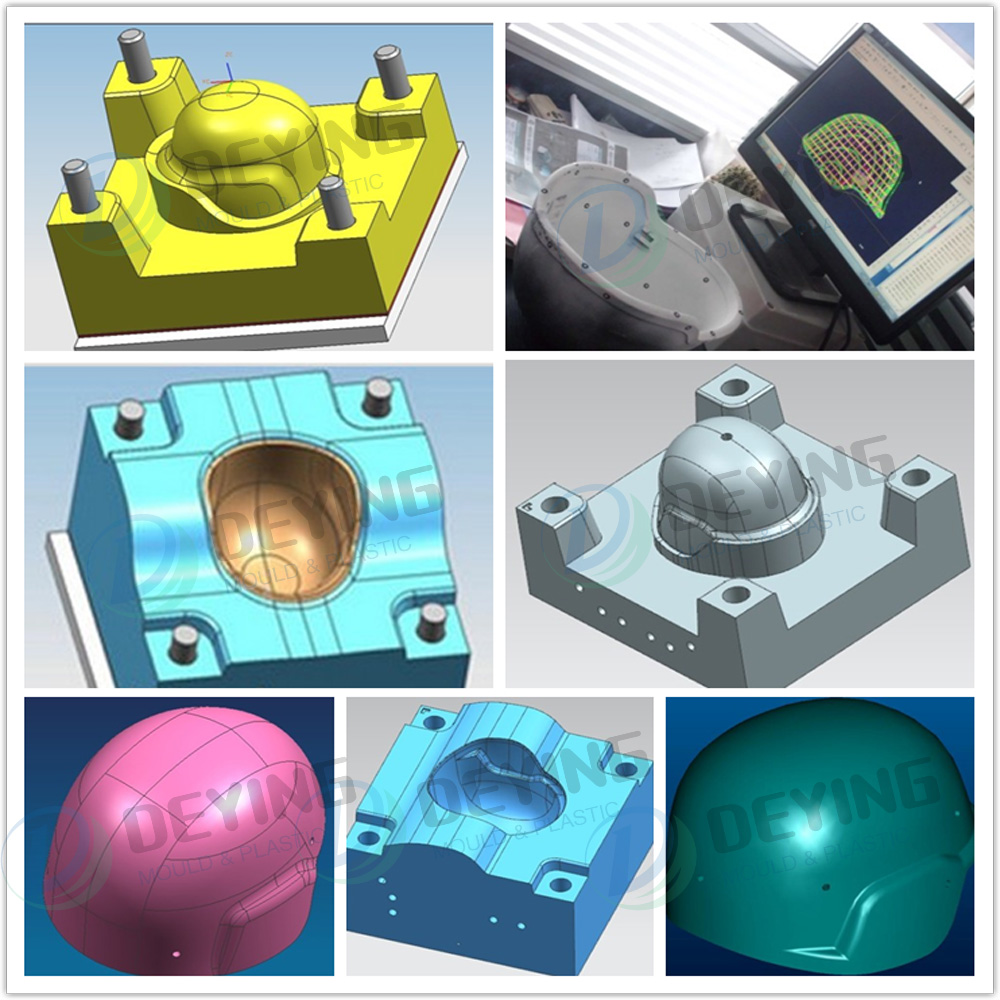

the design was made for compression molding assembly for ballistic helmet

Compression molding (also known as compression molding or compression molding) is an operation that first puts powdered, granular or fibrous plastic into a mold cavity at the molding temperature, and then closes the mold to press to shape and solidify it. Compression molding can also be used for thermosetting plastics, thermoplastics and rubber materials.

Scope of application

Mainly used as structural parts, connectors, protective parts and electrical insulation parts. It is widely used in industry, agriculture, transportation, electrical, chemical, construction, machinery and other fields. Because of the reliable quality of molded products, they have also been used in weapons, aircraft, missiles, and satellites.

MB/Wechat/Whatsapp:+0086-13456489912

sophiemould@foxmail.com