-

compression molding Hot press forming moulds maker

Compression molding is a manufacturing process where a measured amount of molding material that’s generally preheated (typically referred to as a charge) is compressed into the desired form using two heated molds

-

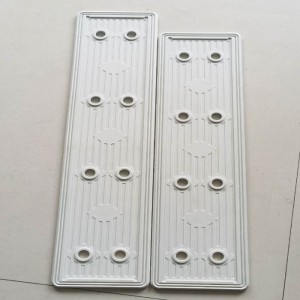

fiberglass mould for Various types of Connector

fiberglass mould for Various types of Connector The grid is interwoven by glass fiber and molded by resin casting. The glass fiber reinforced plastic grid sheet with many regular rectangular and square spaces has two-dimensional homogenous mechanical characteristics. Can be widely used in petroleum, chemical electronics, power, paper, printing and dyeing, electroplating, FRP grating Work platforms, equipment platforms, drilling platforms, walkways, etc. in marine exploration, sewage treatment... -

High quality compression SMC kitchen sink mould

DEYING Mould is a Taizhou mould manufacturer. We provide almost all series of sanitary ware moulds, such as SMC laundry tub moulds.

DEYING has mold finishing technology and mold mirror polishing technology. We have multiple SMC laundry tank mold production lines to ensure that your orders are completed on time and with good quality. For your SMC laundry tank, we will help you achieve efficient production. In addition, relying on DEYING’s accumulated years of FRP material technology, we ensure the service life, smoothness and use experience of your laundry tub, and help you enhance your market competitiveness.

-

China taizhou huangyan compression smc mold cable bracket support mould

SMC has the advantages of superior corrosion resistance, soft quality, easy engineering design, flexibility, etc. Its mechanical properties are comparable to some metal materials, and the products it manufactures have the advantages of good rigidity, deformation resistance, and wide operating temperature range.

At the same time, the size of SMC products is not easy to deform and has excellent heat resistance; it can maintain its performance well in cold and hot environments, and is suitable for outdoor anti-ultraviolet and waterproof functions.

-

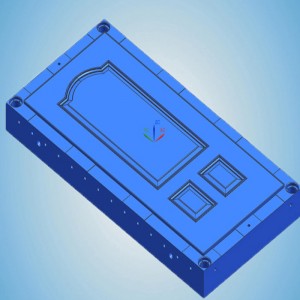

SMC Sheet molding compound compression mould

Sheet molding compound is a type of reinforced polyester containing glass or carbon fibers. The fibers, which are typically 1” or greater in length, are suspended in a bath of resin – usually epoxy, vinyl ester, or polyester.

SMC is a combination of long chopped glass strands, mineral fillers and liquid thermosetting resin in the form of a malleable sheet material. Processing of SMC of is typically done by compression or injection molding.

-

-

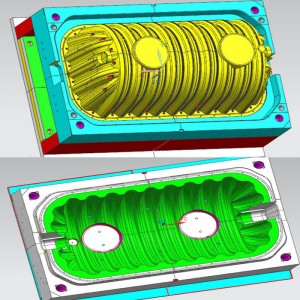

SMC Septic tank mould compression molding

SMC Septic tank mould compression molding fiberglass(FRP) septic tank is made of synthetic resin as matrix and FRP fiber reinforced material. FRP molded SMC septic tank mold advantages: 1. Unique design, pressure and impact resistance. The compressive and impact strength of FRP molded septic tanks is much higher than that of conventional square, cylindrical and spherical domes, and can be used in different situations without any other reinforcement measures. Moreover, the shape of the mechani... -

SMC BMC Compression Insulator block mould

SMC BMC Compression Insulator block mould maker BMC (DMC) dry-type transformer insulation blocks are used for insulation and fixing on dry-type transformers. It can ensure the stability and insulation performance of dry-type transformers during transportation and long-term operation, and can withstand transformers at work. The high temperature and hot air aging generated in the BMC dry type transformer insulating block is integrally molded by high temperature and high pressure. BMC dry-type t... -

smc dmc bmc compression mold for Busbar partition

smc dmc bmc compression mold for Busbar partition Busbar spacers are molded from DMC material With insulation, flame retardant, high strength, good finish, bright colors, long service life, etc. -

Compression mould for Welding clamp

Compression mould for Welding clamp Compression Molds production of DMC material (BMC material) production of electric welding pliers accessories Features: (1) DMC material (BMC material) welding pliers insulation accessories high temperature resistance: due to DMC material (BMC material) glass fiber material thermal deformation temperature in 240 degrees, so BMC welding tongs insulation parts can maintain good steel at high temperatures and can be used at 150 degrees for a long time. Moreov... -

Compression Moulding of Motor terminal

Compression Moulding of Motor terminal Since the motor generally generates heat when it is operated for a long time, the operating temperature of the motor is relatively high. Moreover, the motor must be used in various working conditions, and the use conditions are relatively complicated. Therefore, the motor wiring board material has obvious advantages in temperature resistance, insulation performance and mechanical performance. In the past, ceramic materials were generally used to make the... -

Circuit breaker housing mould

Circuit breaker housing mould In the early 1950s, polyester molding compounds gradually replaced molding compounds such as phenolic and urea-formaldehyde. Later in the UK it was officially referred to as the abbreviation of DMC, DoughMouldingCompound. DMC has the advantages of easy molding, low cost, coloring, and good electrical properties. In the field of electrical appliances, it is possible to manufacture components with complex structures, which are widely used. However, people have also...