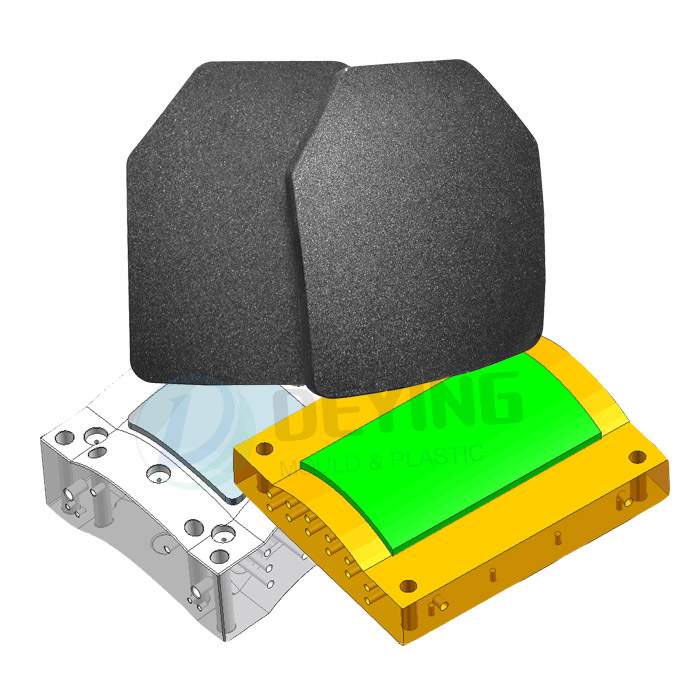

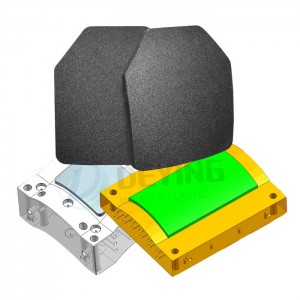

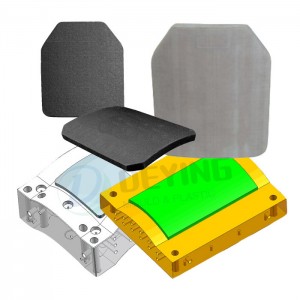

We are professional mould manufacturer for the PE and Kevlar armor plate moulds,2 layers, 3 layers, 6 layers are available,Professional Single curve Bulletproof plate molds Compression Moulds In Zhejiang Taizhou from DEYING

Hard body armor uses layers of firm, durable materials, such as steel, ceramics, ceramic composites, polyethylene, bullet-resistant fibers, and occasionally, materials like Kevlar. The vest carriers themselves are typically made from fabrics such as nylon.

Compression Molding process

1. Clean the mold: clean the resin and debris from the last use in the mold and keep the mold

The tool is clean and smooth.

2. Preheating of the mold: heat treatment of the mold.

3. Apply mold release agent: apply a certain amount of mold release agent to the groove of the mold to prevent subsequent

After heating, the molded product and the mold stick together.

4. Material preparation: prepare the raw materials of the carbon fiber to be made into products and calculate the raw materials

Material area, the number of sheets used.

5. Stacking: Stack the raw materials layer by layer, and pre-press the stacked materials at the same time.

Press into a compact body with regular shape and certain quality.

6. Into the mold: put the stacked raw materials into the mold, and put the plastic gas inside

Bag, mold clamping, put the whole into the mold clamping machine, add a certain constant to the internal plastic air bag

Pressure, constant temperature, set a constant time to cure.

7. Cooling and demoulding: Cool the mold after a period of hot pressing for a period of time,

Then, the mold is opened and demolded.

8. Processing and forming: The products after demoulding need to be cleaned, scrape off the remaining plastic with a steel brush or a copper brush, and blown off with compressed air to polish the formed products to make the surface smooth and clean.

MB/Wechat/Whatsapp:+0086-13456489912

sophiemould@foxmail.com