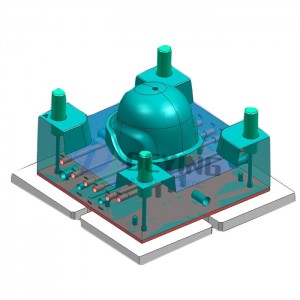

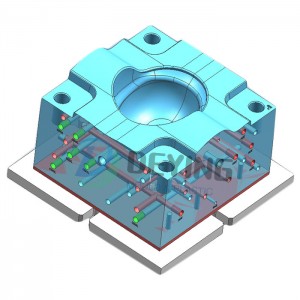

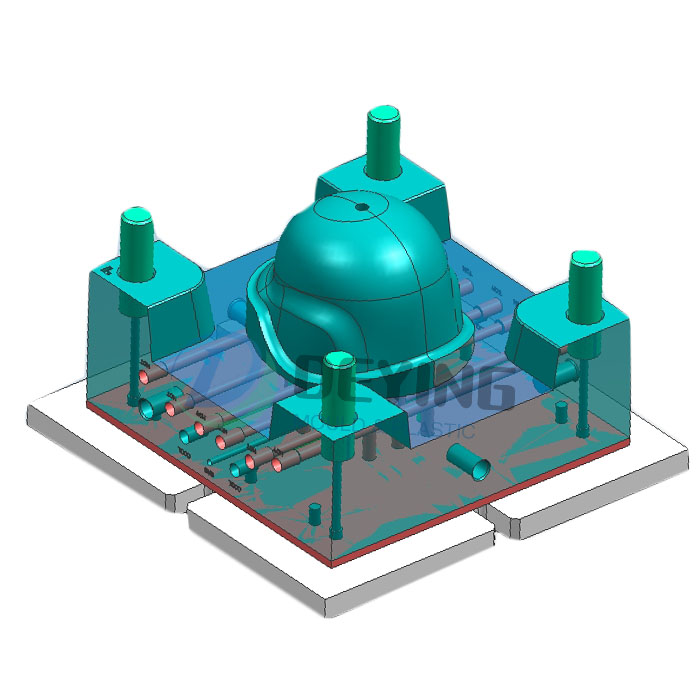

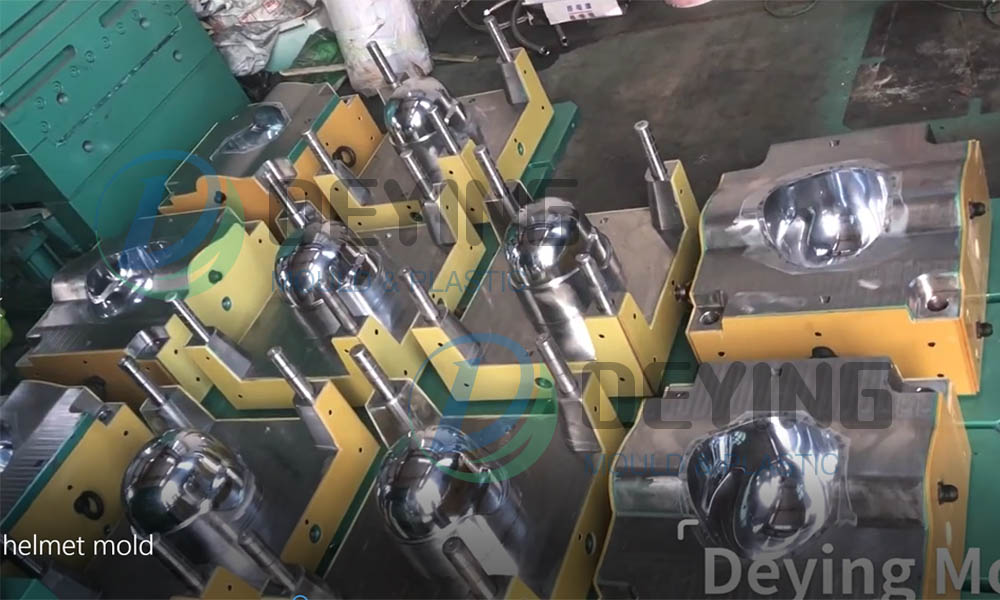

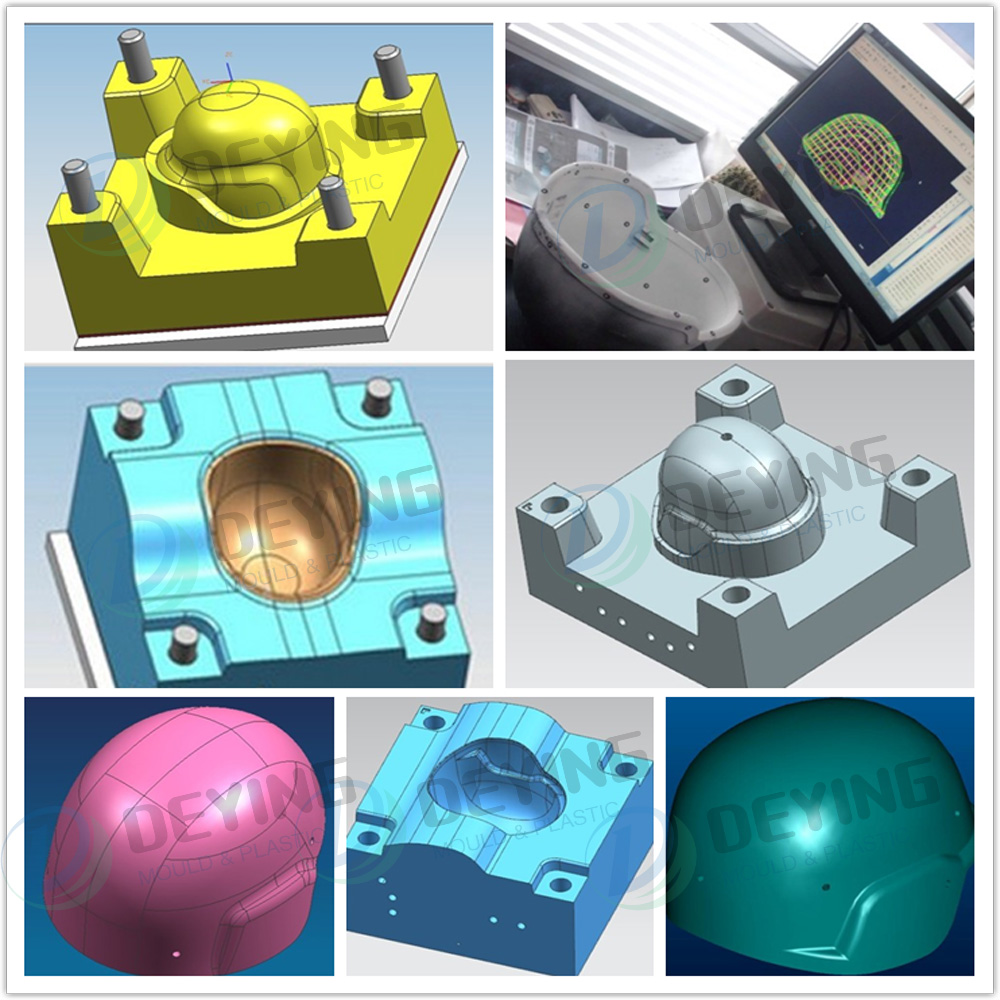

PASGT Full Cut compression ballistic Helmet Mold with dial function,compression mould for Level IIIA ballistic Helmet,we also production Riot Visor or NIJ Level IIIA Ballistic Visor mold

Our advantage:

1. All kinds of molds available.

2. Rapid prototyping available.

3. Safe and fast delivery.

4. Excellent quality and reasonable price.

5. OEM supported.

6. Quality service.

7. Customer's requested logo and welcome customer's design.

8. We have an rich experience and a strict management system for making the mould,professional workers

9.Provide fully 3D design

Our products involve in military products, electronic products, medical products, household items, daily necessities, SMC/BMC/FRP products, etc.

Please don't hestitate to contact us if you need any more information about us.

We will do our utmost to meet your requirments. Thank very much!

Composite molds vary greatly, depending on the industry and application, involving multiple fields such as automotive, electrical, sanitary ware, building materials, and aerospace. Compared with metal molds, composite material molds have many advantages, so what are the advantages of composite material molds?

1. The composite material mold is lighter, and the reduced weight helps in the transportation of the mold.

2. Lower specific heat capacity, less heat required during processing, and easier to control the increase and decrease of curing temperature, thereby shortening the time to pass through the autoclave.

3. The manufacturing and maintenance cost is low, and the composite material mold uses a common master mold to form multiple repeated molds.

As a mature composite mold manufacturer in China, DEYING manufactures various types of glass fiber composite molds (glass fiber reinforced plastic molds, such as SMC, BMC, GMT, LFT), carbon fiber composite molds, and LWRT composite molds.

The molds that DEYING has manufactured include: spoiler templates on trucks, fenders, bumpers, front panel molds, hoods, doors, bottom guards, roofs, seat backs, luggage molds, etc. and electrical appliances on cars. Boxes and bathroom door panels and basin molds, etc. The composite molds we produce have been effectively optimized, have a longer service life, lower manufacturing costs, and their products can achieve higher precision.

MB/Wechat/Whatsapp:+0086-13456489912

sophiemould@foxmail.com