-

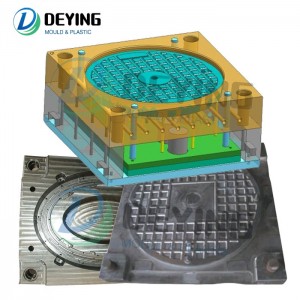

Sheet Molding Compound SMC used for Manhole Cover molds

The FRP manhole cover made by the FRP fiberglass manhole cover mold has a beautiful appearance, and the surface pattern of the manhole cover is exquisitely designed. It can be made into various patterns and colors to beautify the urban environment, which is both beautiful and durable.

-

Resin composite material manhole cover mould compression molds

The resin manhole cover has a long service life, and the quality of the resin manhole cover mold is also a decisive factor. The manhole cover adopts high-performance resin, glass fiber and special production process formula to ensure the penetration of the resin in the glass fiber and greatly enhance the bonding force between the two , So that the material does not produce internal damage under the action of cyclic load, thus ensuring the service life of the product

-

SMC Manhole Cover mold sheet moulding compound FRP manhole cover mould

Resin composite material manhole cover mold production process: it is made of unsaturated resin, glass fiber and other materials and reinforced steel framework through a special production process. After high temperature grinding and pressing, the material has no recycling value and it is very difficult to remove the steel bar ( The cost of removing the steel bar exceeds the value of the steel bar), so it has the function of active anti-theft.

-

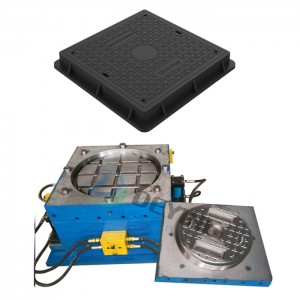

SMC Manhole Cover Compression Molding

DEYING MOULD is the earliest professional manufacturer of FRP molded manhole cover mold products in China. It has been engaged in the design, development and production of SMC/BMC/FRP mold products in the composite material industry for more than 20 years.

-

compression Mould Company Sewerage Manhole Cover molds

Compression molding manhole cover mold-compression mold manufacturing professional manufacturer DEYING mold compression molding is the operation of first putting powdery, granular or fibrous plastic into the mold cavity at the molding temperature, and then closing the mold and pressing it to shape and solidify .

-

SMC Sheet Used for Molded Manhole Covers molding Municipal Facilities mould

DEYING MOLD supplying Municipal manhole cover compression mould. Based on the tenet of “Quality First, Honest Management”, the company wholeheartedly welcomes friends from all walks of life to come and call to discuss cooperation.

-

Size 300*50 Cm Plastic Manhole Cover Mould for Sale

From the perspective of the development of the entire mold industry, although manhole cover molds have made great progress in terms of quality and quantity, both in technology and ability, there is still a big gap compared with the international advanced level, especially in In terms of domestic and foreign exchanges and cooperation, further efforts are needed.

-

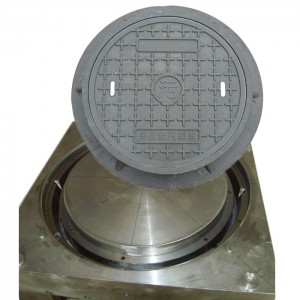

Heavy Duty D400 Dn650 SMC Manhole Cover molding

Manhole cover mold manufacturing industry is a basic industry for municipal building materials and social development. The national manhole cover mold industry is developing rapidly, and the high-tech content is also increasing. The production of manhole cover molds has developed from simple and single to the current precise and complex

-

SMC Sheet Molding Compound mould for Manhole Cover

SMC is a sheet molding compound, which is a kind of mixed polymer resin. The raw materials include glass fiber, minerals, and fillers. Most manhole covers are now produced using SMC materials

-

Heavy Duty 600X600 Sewer Manhole Cover Frame moulds

The new type of manhole cover mold has stronger corrosion resistance and longer life, which effectively reduces investment for customers and improves production efficiency.s.

-

SMC Watertight Manhole Cover mold Composite compression Frame mould

The main function of the manhole cover mold is to improve the quality of drilling and increase the yield. It is an indispensable plate in the current printed circuit board CNC drilling process.

-

Fiberglass Rectangular Manhole Covers and Frames molding

The demand for manhole covers in village construction has greatly increased, and the development of society is more and more inseparable from manhole cover molds. Therefore, manhole cover molds were once sold well, and various types of manhole cover molds have also become the focus of attention.

-

SMC Composite FRP Manhole Cover molds Manufacture in China

Use the correct heat treatment to produce excellent manhole cover molds. The mold temperature rises from time to time. During the production process. When the mold temperature is overheated, it is easy to produce mucous membranes and cause the moving parts to fail.

-

Anti-Theft Manhole Covers molding with Frame mould

Composite manhole covers are widely used. The rare manhole cover molds are mainly divided into the following types: plastic manhole cover molds, composite material manhole cover molds, etc.

-

Drain Inspection Manhole Cover Mould with frame molds

The rapid development of manhole cover molds has driven the entire manufacturing industry to a new stage. At the same time, the gradual decline of low-end molds and the large demand for high-tech molds have caused companies to increase their investment in technology and gradually enhance the technological level of products.

-

SMC FRP Manhole Cover Compression Mould from taizhou huangyan

Fully consider the traffic flow of the road where the manhole cover is located, the durability requirements, the saving of raw materials and the convenience of manufacturing equipment, etc., the manhole cover industry norms. The composite manhole cover mold should be divided into three different use levels to adapt to different roads and sites .

-

Factory Produced Plastic Moulds for Manhole Covers

The development of the manhole cover mold has become the pillar that it contains.In today’s increasingly fierce competition, mold companies want to survive and develop better, they need to carry out differentiated marketing and market segmentation development, to create new highlights and new development outlets for mold products.

-

Customized FRP SMC Steel Mold for Manhole Cover or Frame

The manhole cover mold is released quickly, and can be separated at the time during the production process, and can be continuously produced without interruption, which is dozens of times higher than the production of other molds. It has a long service life and is made of special materials, which can be used continuously for tens of thousands of times

-

Customized SMC Composite Manhole Cover Mouldings

DEYING MOLD is an enterprise specializing in the design and manufacture of new manhole cover molds. It has been engaged in the development and manufacture of new composite manhole cover molds for more than seven years. It has rich production experience and is sold at home and abroad, and is well received by users!

-

Plastic Sewage Manhole Covers mouldings

DEYING MOLD factory manhole cover mold is the main product in the market, which can be customized and designed according to the needs of customers. At present, new mold products have become the main force in the market, and our products are suitable for the needs of various manhole cover manufacturers. They are well received by customers.

-

compression manhole cover molding for fire inspection hydroelectric

The manhole cover mold occupies the dominant position in the entire mold industry. This is because the development of molds in recent years has been very rapid. The relevant domestic departments have strongly supported the mold industry, and the application of mold products is very broad, which provides for the development of the manhole cover mold industry Very good market.

-

Manufacturers supply sewage meter well molds

The production of manhole cover molds has moved from the traditional manual production method led by master locksmiths to the era of modern industrial production that generally adopts digital and information design and production technologies

-

Professional SMC and BMC Watertight Manhole Cover Moldings

DEYING Manhole Cover Mould Factory is a professional manufacturer of manhole cover moulds, with many years of mould sales experience. The various products produced by our factory have reached the review and quality verification of the relevant national departments. Our factory has its own R&D team to make its products continue to mature and walk in the forefront of the industry.

-

SMC Manhole Cover Telecom Cover Moulds

The SMC manhole cover mold has a very good decorative effect, and the design is very strong. Different patterns can be designed on the surface to beautify the environment. It has very strong wear resistance and corrosion resistance. The FRP manhole cover mold has a high load capacity and no noise will occur when the vehicle passes in. , Has a strong service life, very good sealing, can effectively prevent harmful gas leakage and reduce environmental pollution.