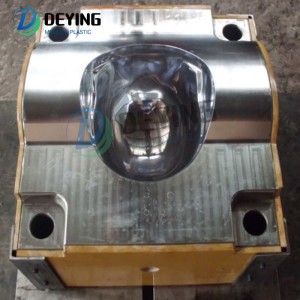

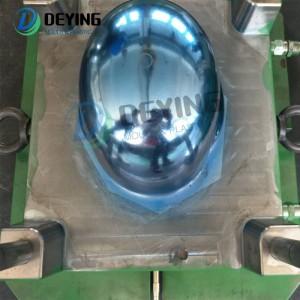

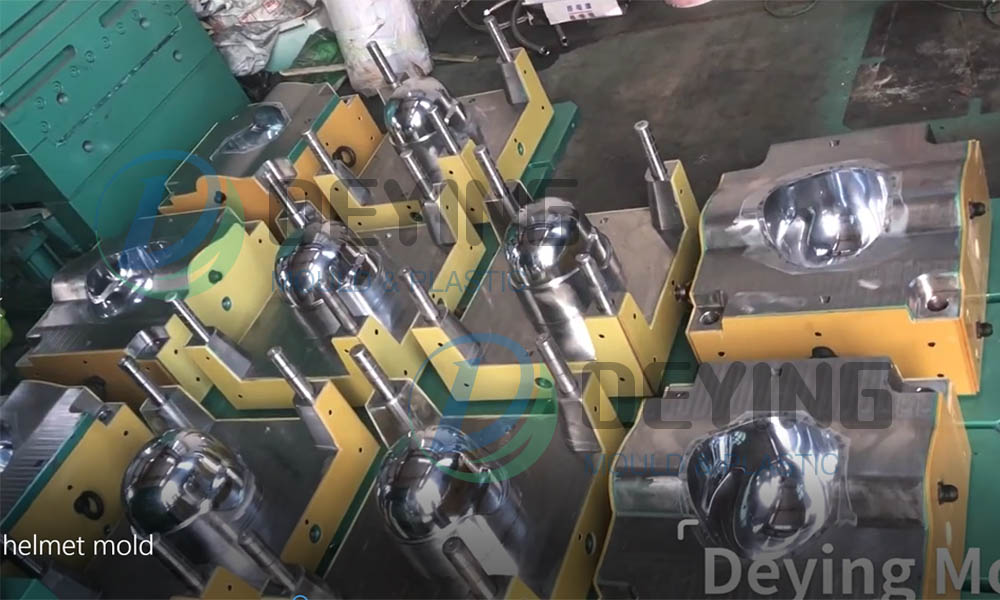

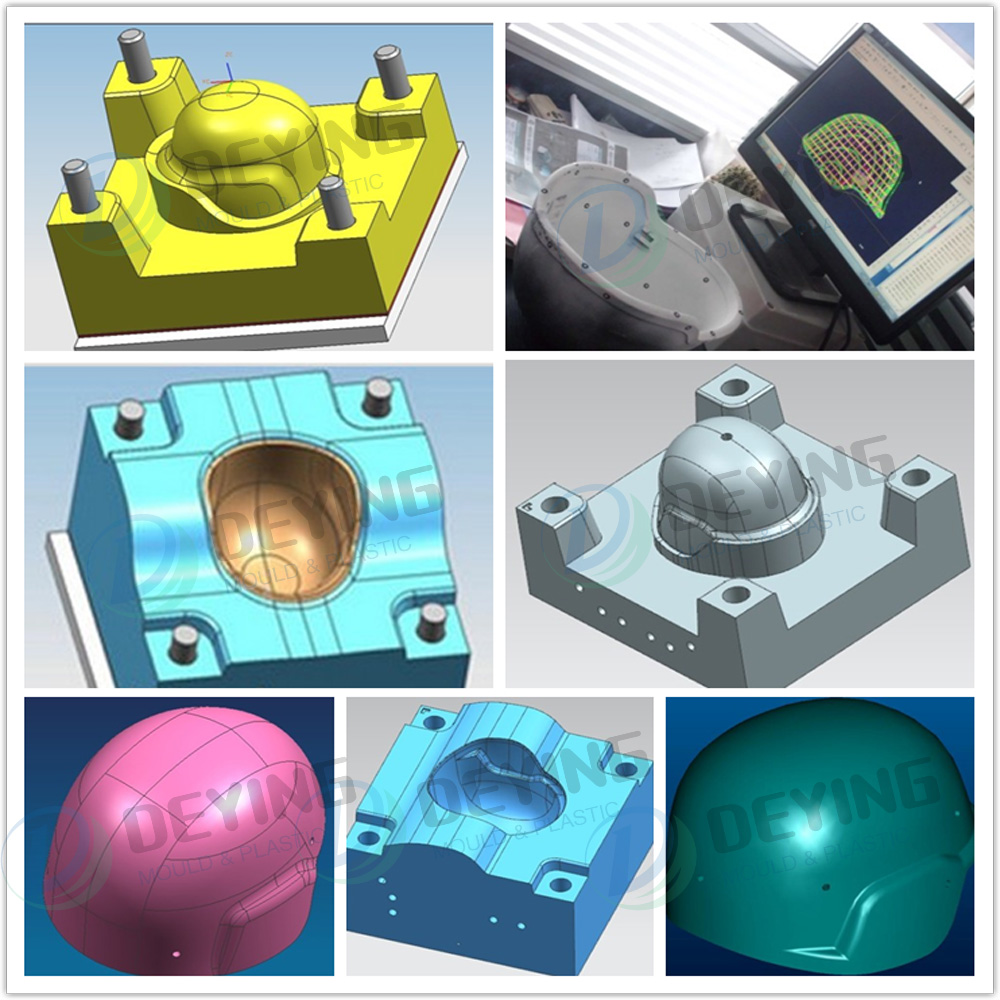

Compression Military Ballistic Helmet Mold in China all kinds of Moulds Making, best compression mold for bulletproof military helmet that are available in many different shapes and size.

Production by hydraulic press,PE helmet cycle time will 50-60 minutes,because it needs to heating and then cooling

A method for manufacturing a high performance thermoplastic matrix composite ballistic helmet includes forming/shaping a highly consolidated helmet preform free of wrinkles and with no cuts or seams from a flat stack of 0/90 uni-directional prepreg layers using a pressure forming process

The wrinkle free and no cuts pre-formed helmet shell is pre-heated and placed between match-metal dies in a compression molding press to be molded under constant pressure during heating at high temperature and cooling down below 200° F. in less than 45 minutes. Or molded under constant pressure at high temperature for less than 20 minutes and then the molded helmet is removed from the compression molding press and placed in a hydroforming machine to be cooled down in less than two minutes under a very high pressure while the thermoplastic matrix solidify during cooling down.

MB/Wechat/Whatsapp:+0086-13456489912

sophiemould@foxmail.com